We now have a highly efficient workforce to deal with inquiries from consumers. Our goal is “100% consumer fulfillment by our product or service excellent, selling price & our crew service” and get pleasure from a great popularity among clientele. With lots of factories, we can offer a wide vary of 18 Years Factory China High Speed Metal Stud and Track Roll Forming Machine, You would not have any communication problem with us. We sincerely welcome clients all over the world to get hold of us for organization cooperation.

We now have a highly efficient workforce to deal with inquiries from consumers. Our goal is “100% consumer fulfillment by our product or service excellent, selling price & our crew service” and get pleasure from a great popularity among clientele. With lots of factories, we can offer a wide vary of c channel bending machine, C Channel Forming Machine, C Channel Machine, C Channel Roll Forming Machine, c channel rolling machine, c stud roll forming machine, channel machine manufacturer, channel roll former, China Metal Stud and Track Roll Forming Machine, High Quality Stud and Track Machine, roll former c channel, Roll Forming Machine, Now the competition in this field is very fierce; but we are going to still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. “Change for the better!” is our slogan, which means “A better world is before us, so let’s enjoy it!” Change for the better! Are you ready?

Description

The Stud and Track Roll Forming Machine, as known as Hat Shape Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Roll Forming Machine, Wall angle Roll Forming Machine, Ceiling Roll Forming Machine Light Steel Keel Roll Forming Machine etc. can produce studs, tracks and many other shapes derived form Shape C.

The thickness is normally can be formed at 0.25-1.2mm .

If you need to more efficiency then we recommend you adpot the Flying shear with No-stop system .

The Max. whole line speed can be reach at 40m/min.

If you want to produce more than one profile in one machine, we recomend you the double rows forming machine and triple rows forming machine to save space and economy.

Technical Specifications

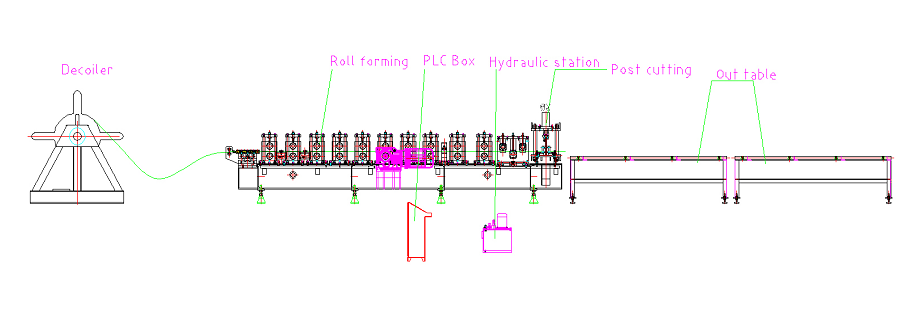

Flow Chart

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table