All we do is usually connected with our tenet ” Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for 2019 Good Quality China 2015 Stud and Track Roll Forming Machine, We sincerely welcome abroad buyers to consult for that long-term cooperation plus the mutual advancement.

All we do is usually connected with our tenet ” Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for c channel bending machine, C Channel Forming Machine, C Channel Machine, C Channel Roll Forming Machine, c channel rolling machine, c stud roll forming machine, channel machine manufacturer, channel roll former, China Stud and Track Roll Forming Machine, roll former c channel, Roll Forming Machine, Stud Roll Forming Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade items in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Description

The Stud and Track Roll Forming Machine, as known as Hat Shape Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Roll Forming Machine, Wall angle Roll Forming Machine, Ceiling Roll Forming Machine Light Steel Keel Roll Forming Machine etc. can produce studs, tracks and many other shapes derived form Shape C.

The thickness is normally can be formed at 0.25-1.2mm .

If you need to more efficiency then we recommend you adpot the Flying shear with No-stop system .

The Max. whole line speed can be reach at 40m/min.

If you want to produce more than one profile in one machine, we recomend you the double rows forming machine and triple rows forming machine to save space and economy.

Technical Specifications

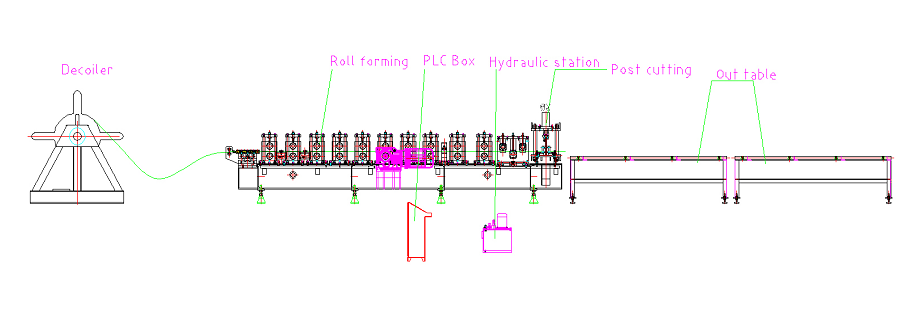

Flow Chart

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table