Descripción

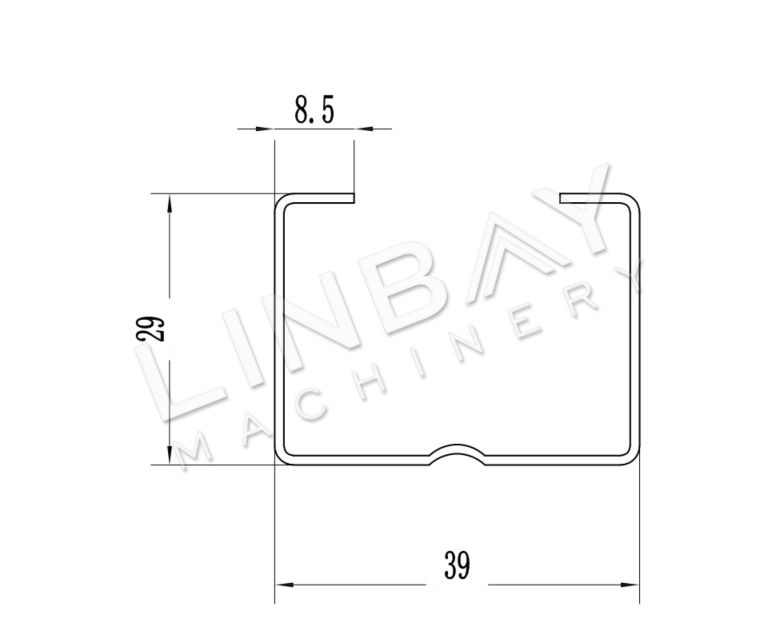

C profile is widely used at many different industries. For example, C profile steel can be used as purlin in construction or stud in drywall system, also can be used as ladder rung at cable ladder system, besides it is also bracing at shelf system(in Spanish it is called riostra). When it is bracing, the thickness is around 0.9-2mm, 25mm*12.5mm small size, and we can also make any size according to your drawing. Normally the raw material is galvanized steel or hot rolled/cold rolled steel.

Linbay Machinery produce bracing roll forming machine, we have exported it to Vietnam, India, Argentina, Chile, Colombia etc. We have lots of experience. The production line has a speed around 10-15m/min, including the cutting and punching. One machine can make several sizes, and it’s easy to change sizes by manually changing the spacers, here is the video you can check how it works: https://youtu.be/QrmTuq0h50s

Linbay Machinery is professional roll forming machine manufacturer, we offer you high-quality equipment and best port-sales service. Now the online installation during COVID-19 is free.

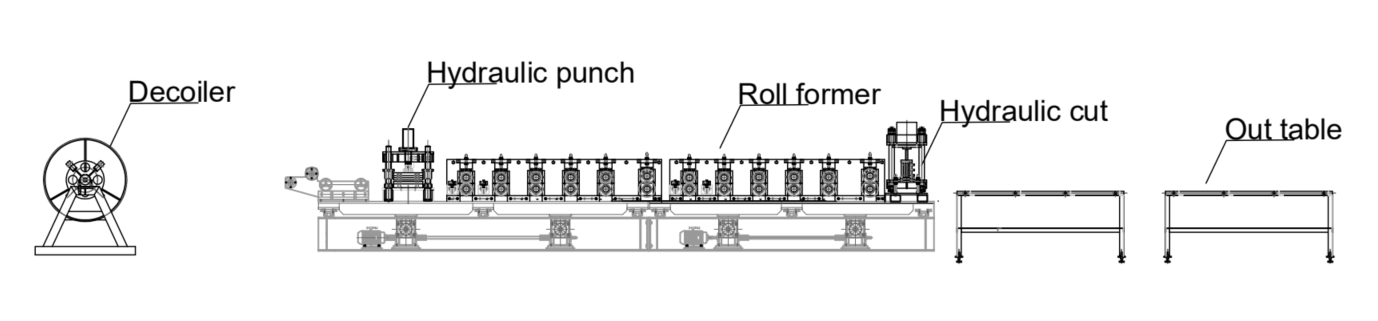

Flow chart:

Decoiler--Hydraulic punch--Roll former--Hydraulic cut--Out table.

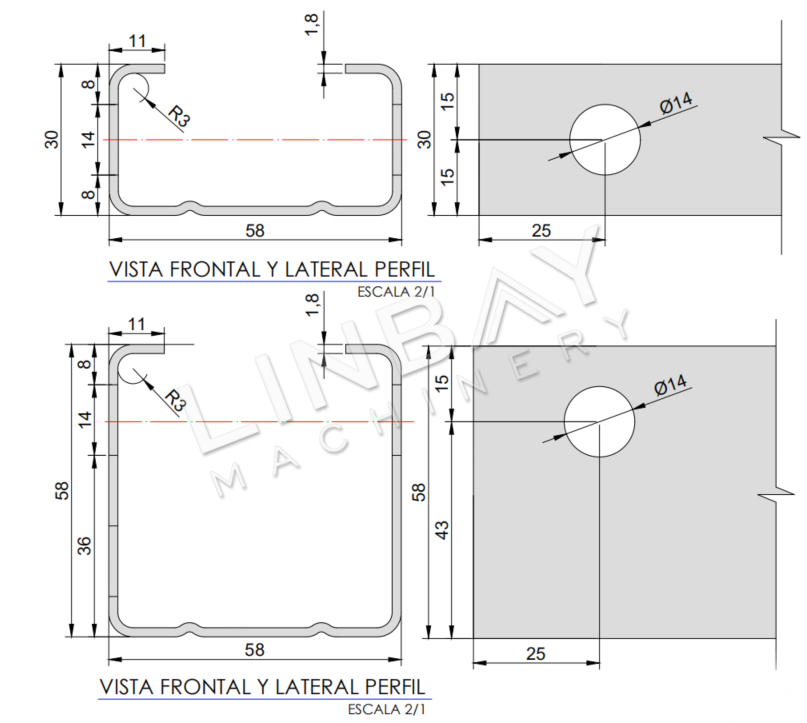

Profiles

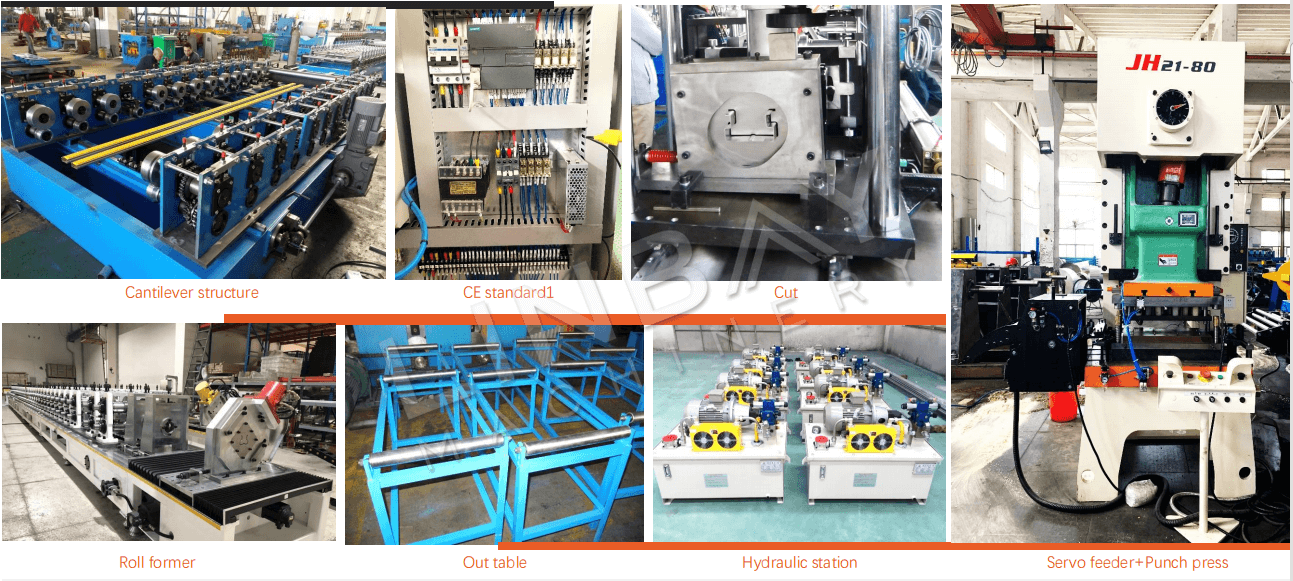

Whole Production Line of Pallet Upright Rack Roll Forming Machine

Machine Pictures

Technical Specifications

How does LINBAY MACHINERY make installation during COVID-19?

The installation of roll forming machine during COVID-19 is for free!

Hereby LINBAY will explain how we do the installation of our roll forming machine.

First, we adjust the machine in our plant, we will ask which size you are going to produce first, we put the machine in the size it is going to produce and adjust all the correct parameters before the shipment, so you do not need to change anything when you got this machine.

Second when we disassemble the machine for debug, we take videos so that you know how to connect them. Each machine has its video. In the video, it will show how to connect the cables and tubes, put the oils, put together the physical structures etc ...

Here is an example of that video: https://youtu.be/p4EdBkqgPVo

Third, when you receive the equipment, you will have a wahtsapp or wechat group, our engineer (He speaks English and Russian) and I (I speak English and Spanish) will be in the group to support you in any doubt.

Fourth, we send you a manual in English or Spanish so that you understand all the meanings of the buttons and how to start the machine.

We have a case that my client from Vietnam received his machine on November 25, and put it on brand at night, and started producing on November 26. And besides this, we have achieved many successes in installing more complicated machines. There is no problem with the installation of your machine. LINBAY offers the best quality and the best service for our clients, especially in this situation. You don't have to wait until the COVID pass. You can produce the profiles right away with our machines.

Purchase Service

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

1-300x168.jpg)