Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Cheap PriceList for China Fully Automatic DIN Rail Steel Structure Cold Rolling/Roll Forming Machine, Quality is factory’s life , Focus on customers’ demand is the source of company survival and development, We adhere to honesty and good faith working attitude, looking forward to your coming !

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for cable ladder forming machine, Cable Tray, China Cold Roll Forming Machine, cold bending roll machinery, Din rail, din rail forming machine, din rail forming machiney, din rail making machine, din rail production line, din rail roll former, electrical enclosure bos, electrical enclosure frame, electrical junction box, Galvanized Steel Roll Forming Machine, ladder cable tray roll former, metal steel forming machinery, stainless steel roll forming machine, Steel Roll Forming Machine, steel roll making machine, With the highest standards of product quality and service, our products and solutions have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We’ve been very happy to serve customers from all over the world!

Description

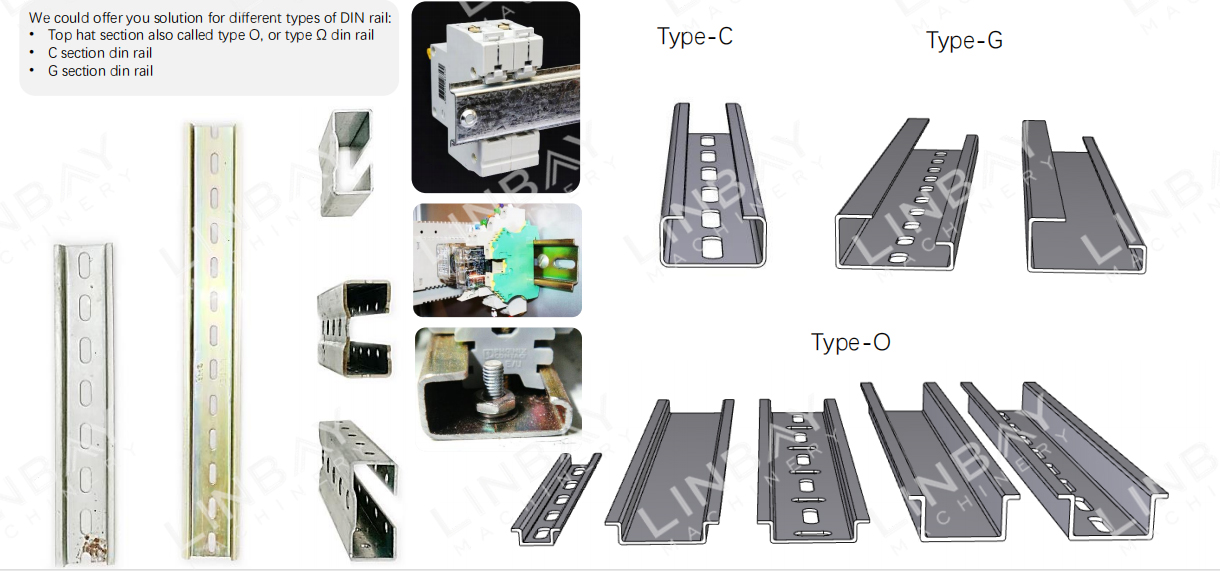

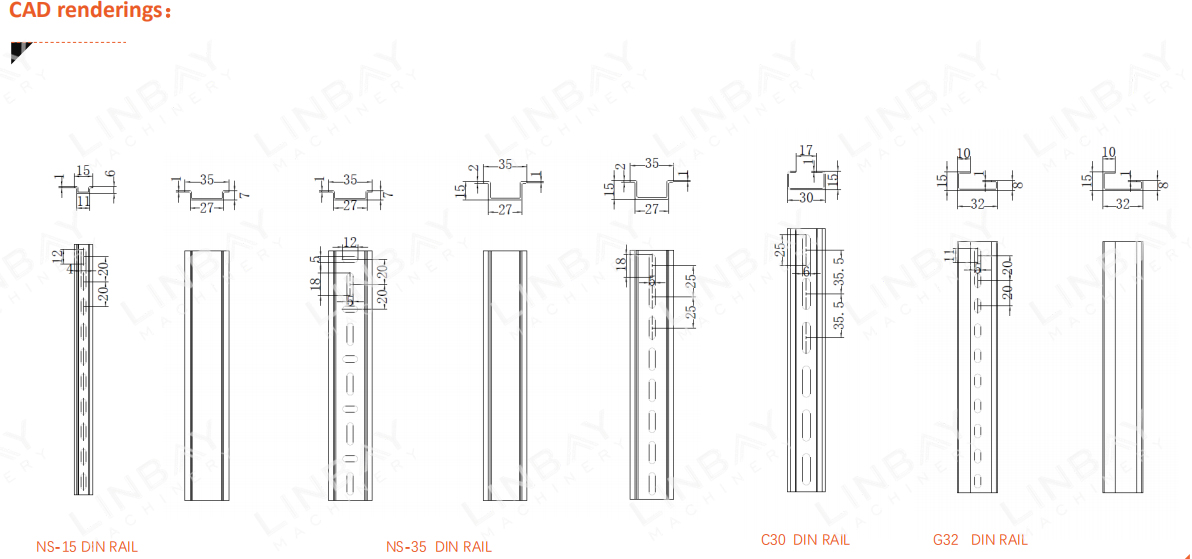

Din rail roll forming machine is to produce DIN rail for electrical cabinet, which is widely used for mounting circuit breakers and industrial control equipment inside equipment racks. Machinable materials usually are Zinc-plated steel, Aluminum, Stainless steel etc with sheet thickness 1 – 1.5mm.

Normally Din rail roll forming machine produce one size, but in our Argentine case we offer a double row roll forming machine, it could be more economic and competitive when you need produce two or more size, also we could make triple-row if you have one more size. Line working speed could reach 30m/min.

Our machine could produce DIN rails meet different standard and series in different countries:

⚫ IEC / EN 60715 – 35×7.5

⚫ IEC / EN 60715 – 35×15

⚫ EN 50022 in Europe

⚫ BS 5585 or BS 5584 in British

⚫ DIN 46277 in German

⚫ AS 2756.1997 in Australia

⚫ USA series: TS35, TS15

⚫ Argentina series: NS35

⚫ C section series: C20, C30, C40, C50

⚫ G section series: EN 50035 G32

Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Application

3D-Drawing

Real Case A

Description:

This DIN rail roll forming machine could make 4 types of NS35 Series Din rail, very economic and competitive. In this case, we use a double row structure to produce 2 different sizes, no need to change any parts of machine, everyone could operate it with no difficulty. We could also offer you a faster line, whose line speed can reach 30m/min.

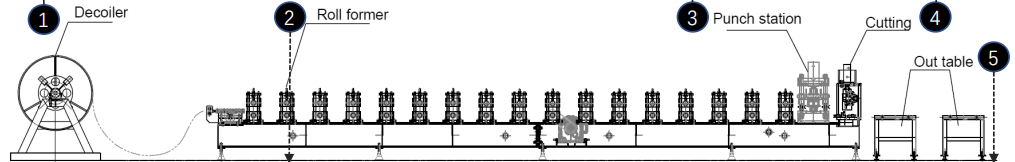

Whole Production Line of Din Rail Roll Forming Machine

Technical Specifications

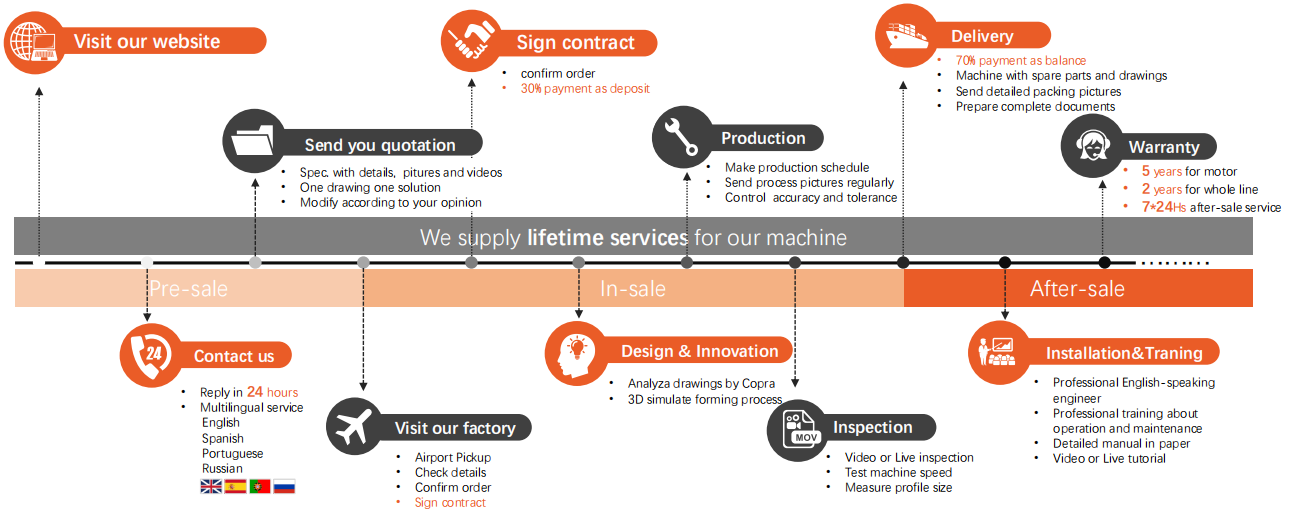

Purchase Service

Q&A

1. Q: What kinds of experience do you have in producing DIN rail roll forming machine?

A: We have experience of exporting our Din rail roll formers to America, Mexico, Russia and Philippines etc. We have produced variety of Din rail roll forming machines which can produce such as Top hat rail (IEC/EN 60715, TS35), C section rails (C20, C30, C40, C50), G section rails (EN 50035, BS 5825, DIN46277-1).

2. Q: How many sizes can be made in one machine?

A: We can produce double-row, even triple -row DIN rail roll forming machine, so it can produce two or more sizes.

3. Q: What is delivery time of din rail roll forming machine?

A: 30 days to 50 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. if you want a higher speed like 40m/min, we give you a solution with rotary punch system, which punch speed is up to 50m/min.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching molds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will

handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table