Description

Cut to Length lines is used for uncoiling, straightening, gauging, cross-cutting to length and stacking work. It performs a variety of operational functions including cut sheet leveling, edge trim (if required), cut to length and stack sheets and plates. The machine is suitable for cold rolled steel and hot rolled carbon steel, stainless steel PPGI, GP, Aluminium and all kinds of coated metal materials. The advantage of Linbay's Cut to Length line is: 1. High degree of automation; 2. Simple and reliable operation; 3. High precision of length; 4. High flatness of sheet material; 5. Neat stacking.

Linbay Machinery is professional to make slitting machines and cut to length machines, we have exported to Iraq, Malaysia, Saudi Arabia, Egypt, Australia, Salvador,India, Sri Lanka, USA etc. We have rich experience, powerful technical force and a perfected quality control system.

Linbay has different model for our customers to choose according to your condition. CTL1250 is suitable for thick panel and small coils, CTL1600 is a standard automatic cut to length machine, working speed is 60m/min, suitable for 0.3-3mm thickness carbon steel and galvanized steel, which is most customers' first choice. We export a large amount of this model every year, so the production cost is lower and price is competitive.

Linbay adopts pneumatic shearing machine, but now we have a new tech which is equipped with a flying hydraulic cutting machine. This device is special for thick panel cut to length line to make speed up.

Also Linbay offers cut to length machine for thickness panels, up to 12mm like model CTL2000PRO. Model CTL2000PRO has a end trim device to slit the flange of coil. We offer a variety of customized cut to length machines for you. Please contact us for more details.

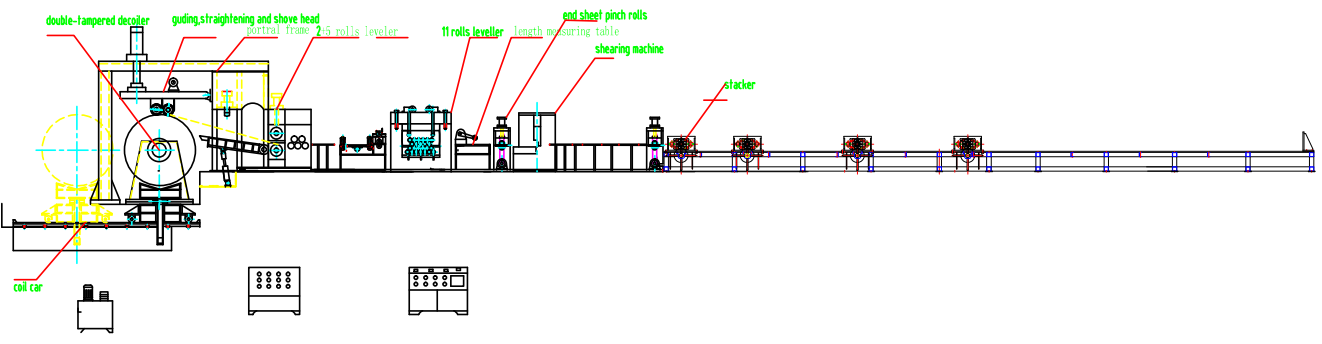

Machine flow chart

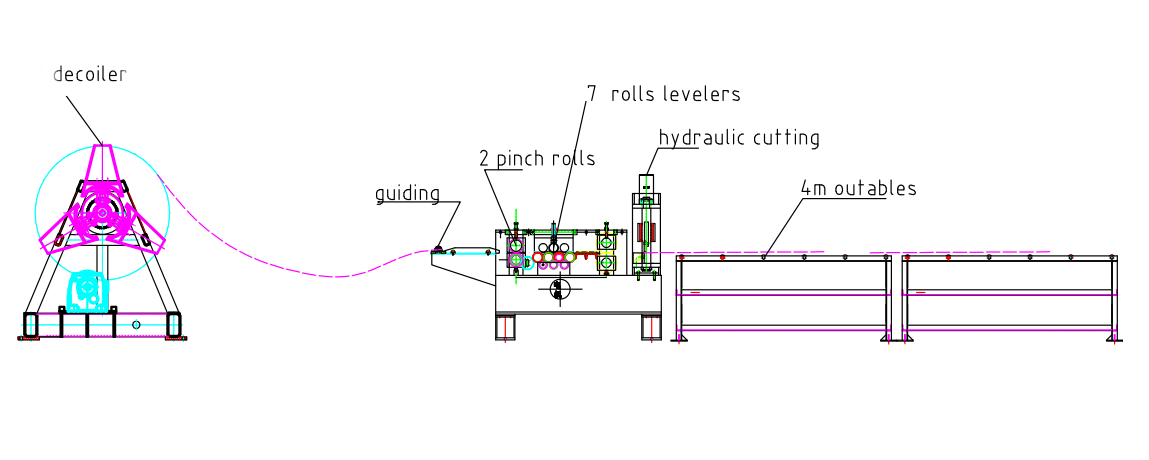

Model CTL1250

Hydraulic decoiler--Guiding--2 pinch rollers+7 leveling rollers--2 pinch rollers--Hydraulic cut--Out table

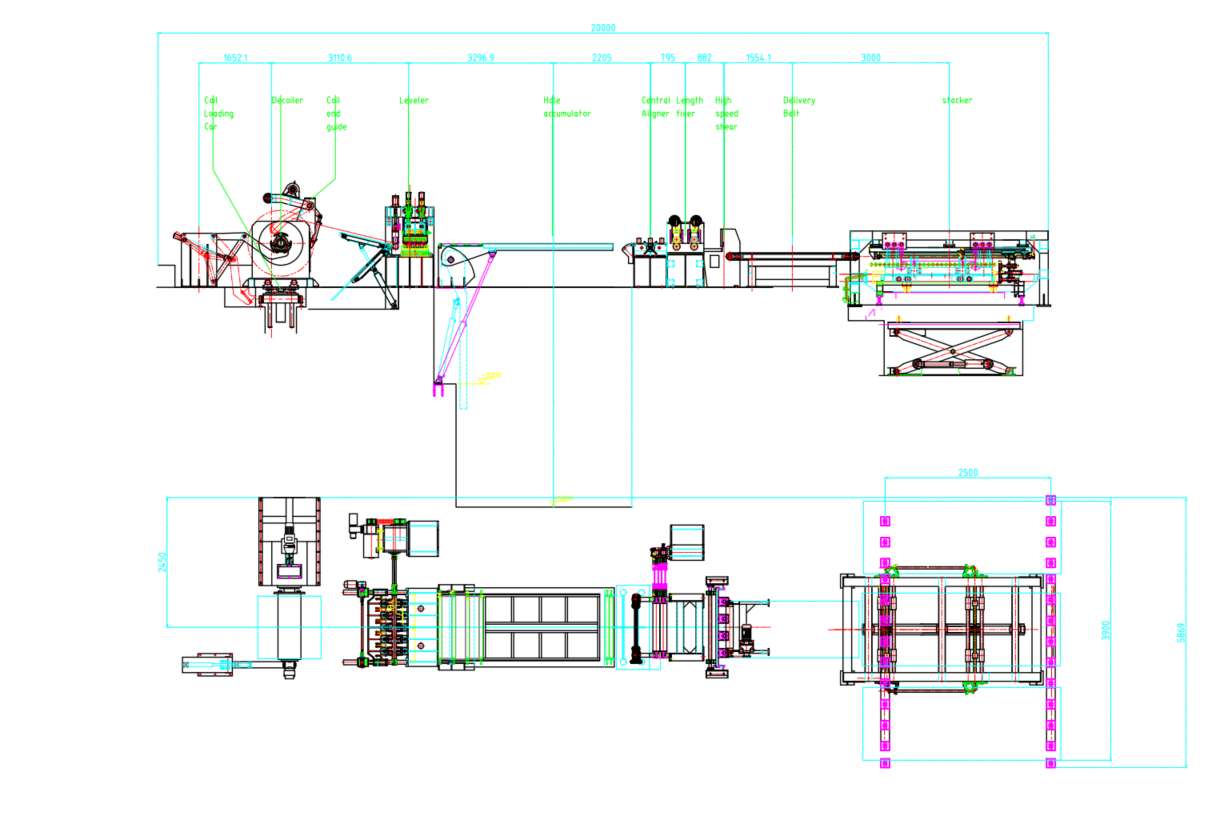

Model CTL1600

Hydraulic decoiler&support arm&coil car--Shovel head&press head--2 pinch rollers+15 leveling rollers--Loop--Center aligner--Length encoder--High speed pneumatic shearing machine--Transportation belt--Auto stacker

Model:CTL1600C

Hydraulic decoiler&support arm&coil car--Shovel head&press head--Center aligner--15leveling rollers--Pinch rollers--Pneumatic shearing machine--Transportation belt--Auto stacker

Model:CTL1600 PRO

Portal frame hydraulic decoiler&coil car--Shovel head&press head--2 pinch rollers+5 leveling rollers--Center aligner--11 leveling rollers--Length encoder--Pinch rollers--Pneumatic shearing machine--Transportation belt--Auto stacker

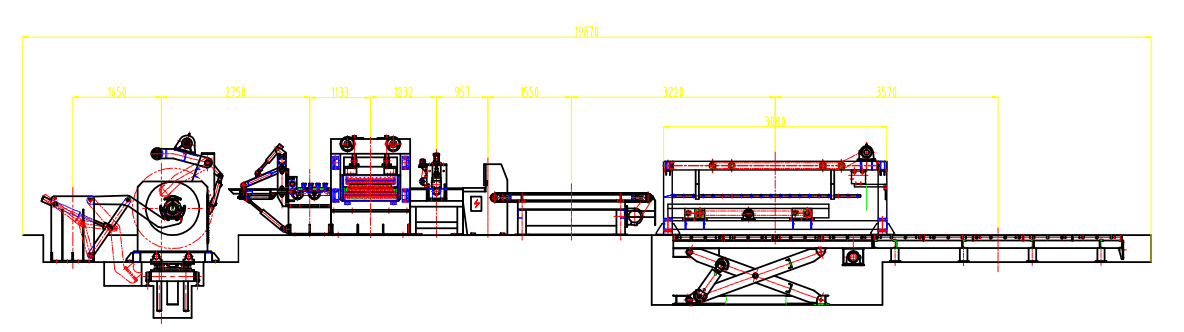

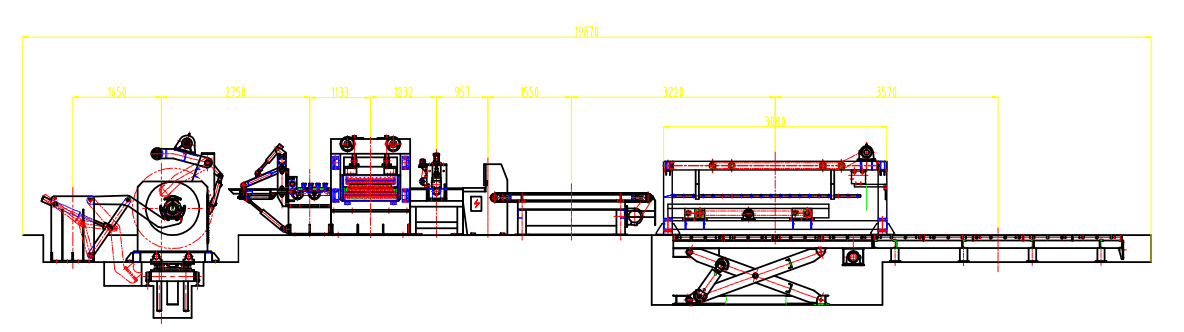

Model:CTL2000

Hydraulic decoiler&coil car--Shovel head&press head--2 pinch rollers+5 leveling rollers--Loop--Pinch rollers--Center aligner--17 leveling rollers--Length encoder--Pneumatic shearing machine--Transportation belt--Auto stacker

Model:CTL2000 PRO

Portal frame hydraulic decoiler&coil car--Shovel head&press head--Center aligner--slitting machine--Scrap recoiler--2 pinch rollers+11 leveling rollers--Pneumatic shearing machine--Transportation belt--Auto stacker

Technical Specifications

Machine Pictures

CTL1250

CTL1600

CTL2000

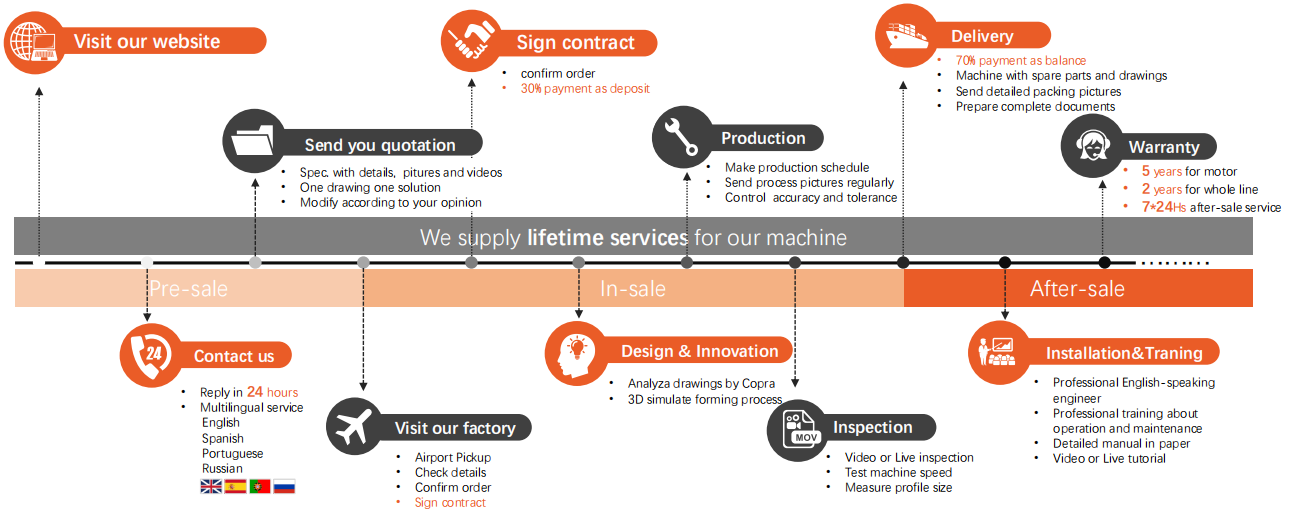

Purchase Service

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table