video

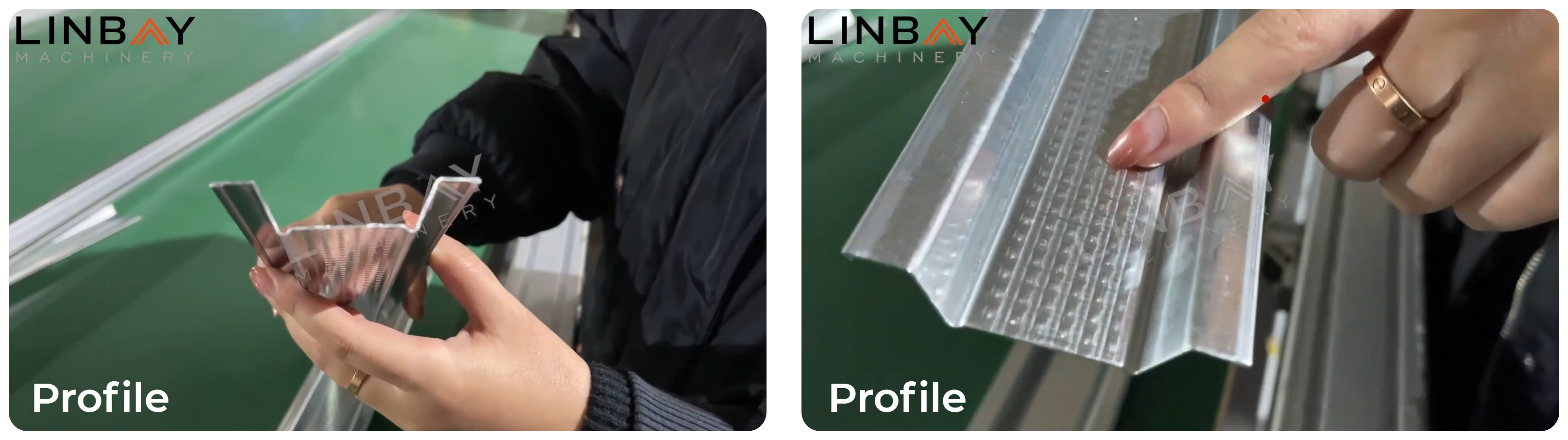

Profile

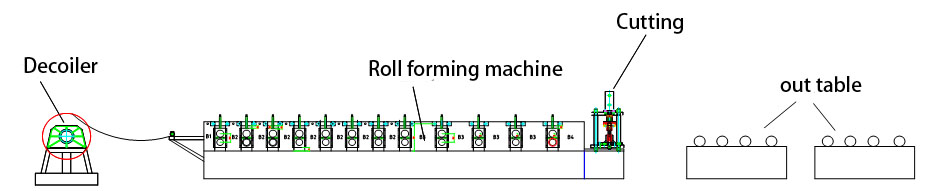

Flow chart

Manual decoiler-Roll former-Hydraulic cut-Out table

Manual decoiler

This is a 3-ton manual decoiler without power. Steel coils are lead by the roll forming machine. Depending on the customer's budget, there is also the option of a hydraulic decoiler powered by a hydraulic station, enhancing the efficiency of the decoiling process and the entire production line.

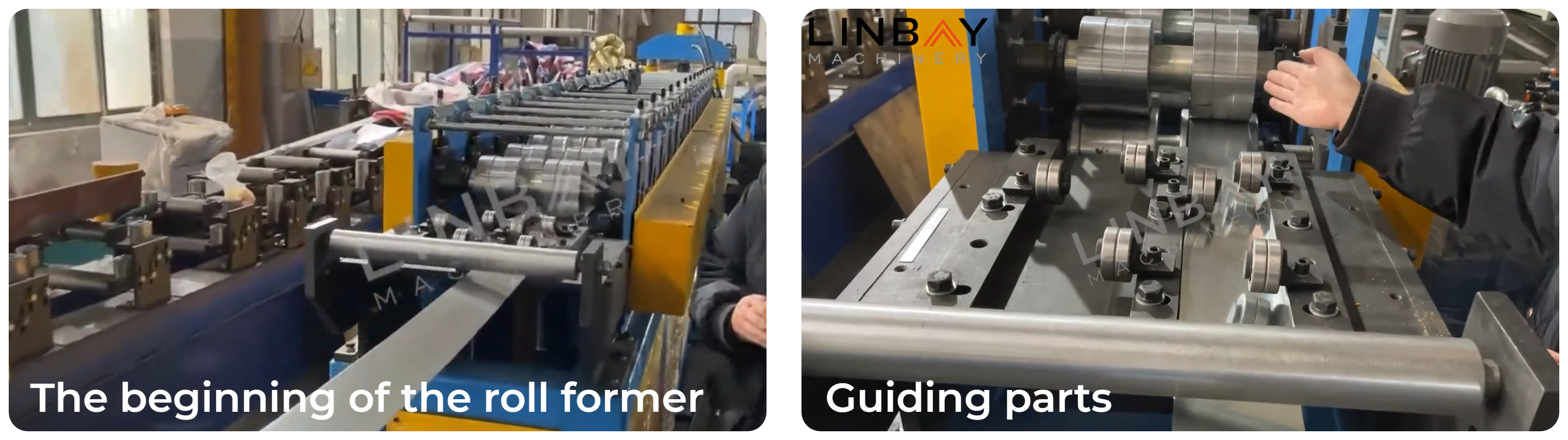

Guiding parts

Steel coils pass through guiding bars and guiding rollers before entering the roll former. Multiple guiding rollers are strategically placed to maintain alignment between the steel coil and the machine, ensuring the profiles formed remain distortion-free.

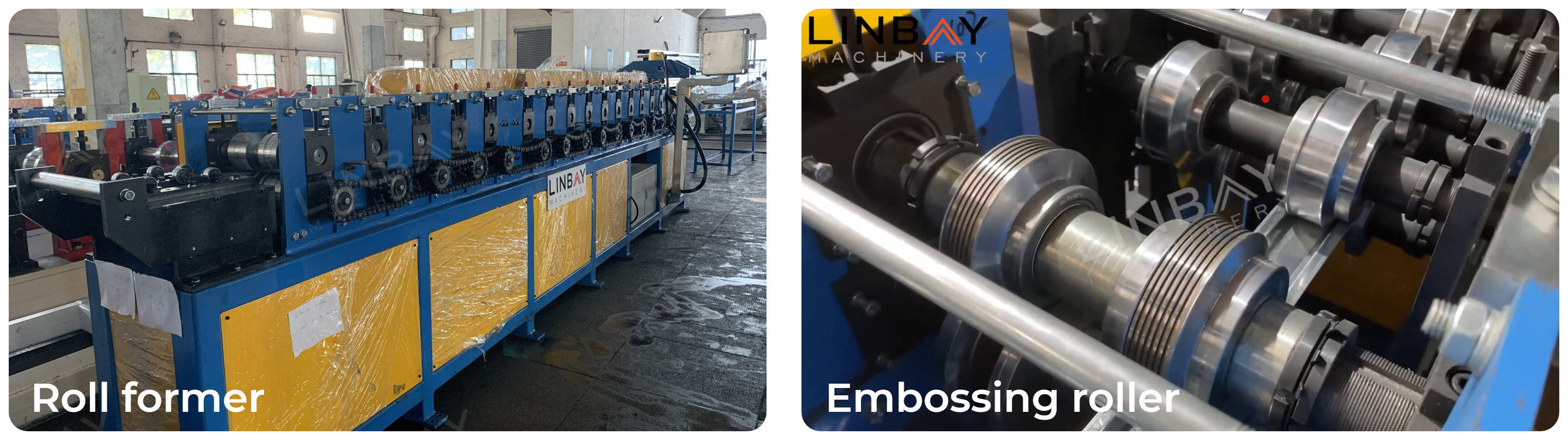

Roll former

This roll forming machine features a wall panel structure and a chain driving system. Notably, it has a dual-row design, enabling the production of two different sizes of omega profiles on a same machine. As the steel coil enters the roll former, it passes through a total of 15 sets of forming rollers, ultimately producing omega profiles that match the customer's specifications.

To meet this customer's requirements, we've incorporated an embossing roller for creating patterns on the profile surface. It's important to note that for this dual-row structure to be effective, the height, thickness, and number of forming stations for the two sizes need to be similar.

Hydraulic station

Our hydraulic station is equipped with cooling fans to help maintain the temperature and efficiency of continuous operation.

Encoder&PLC

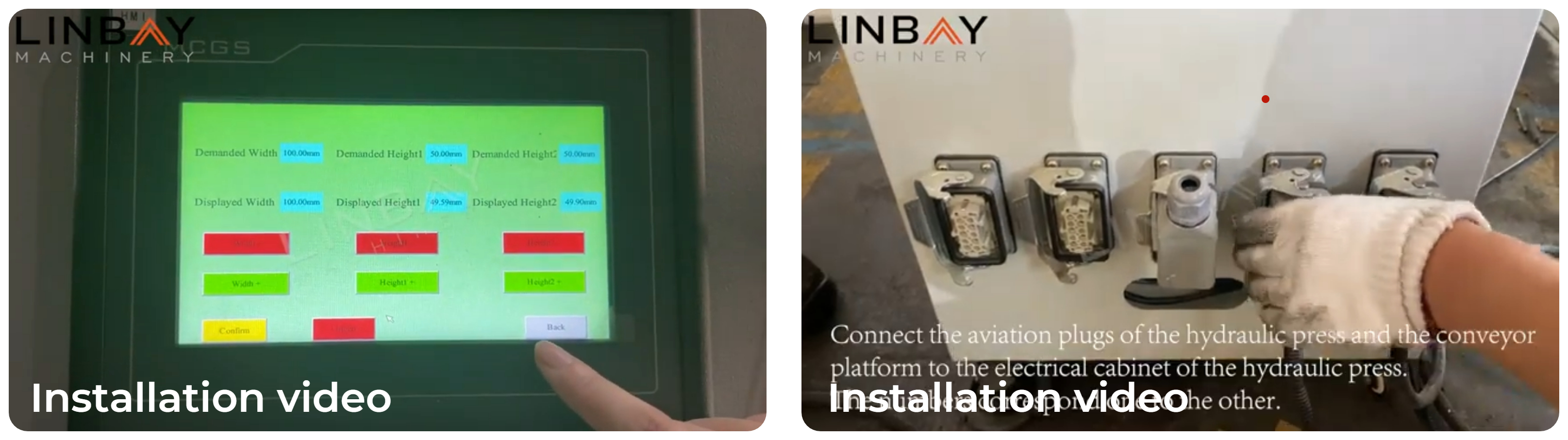

The PLC control cabinet is portable and doesn't take up much space in the factory. Workers can control production speed, set dimensions, and cutting lengths through the PLC screen. The production line includes an encoder, which converts sensed steel coil length into electrical signals relayed to the PLC control panel. This precision control keeps cutting errors within 1mm, ensuring high-quality products and minimizing material waste due to inaccurate cutting.

Before shipping, we debug the machine with suitable steel coils until both rows of forming channels consistently produce quality profiles.

We also provide installation manuals, user guides, and instructional materials in English, Spanish, Russian, French, and other languages. Additionally, we offer video resources, video call assistance, and on-site engineering services.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table