Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Europe style for China Rolling Slat Door Frame Making Machine, By 10 years effort, we attract customers by competitive price and excellent service. Moreover, it’s our honest and sincerity, which help us always be clients’ first choice.

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for China Rolling Slat Door Frame Making Machine, PU wall panel machine, Roll Forming Machine, Roller Shutter Door Forming Machine, Roller Shutter Door Machine, Roller Shutter Slat Roll Forming Machine, rolling shuter machine price, rolling shutter machine manufacturer, Rolling Shutter Machine Price, shuter cover machine, Shutter Door Roll Forming Machine, shutter door roll forming machines, shutter slat door machine, shutter slat roll former, slat roller door machine, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a “people-oriented, meticulous manufacturing, brainstorm, construct brilliant” organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we’re planning to be happy to serve you.

https://www.youtube.com/watch?v=lBUci80mMfw&list=PLnd3xD0RwH9Ti05FCZpcKzaIIYk73K9LZ&index=13&t=0s

Description:

Roller Shutter Door Roll Forming Machine produce stainless steel rolling shutter doors and color steel rolling shutter doors. We use punching press to make different hollow-carved designs. If you ask, we can also produce PU Rolling Shutter Door Roll Forming Machine, which machine can make fire resistance and thermal insulation rolling shutter doors.

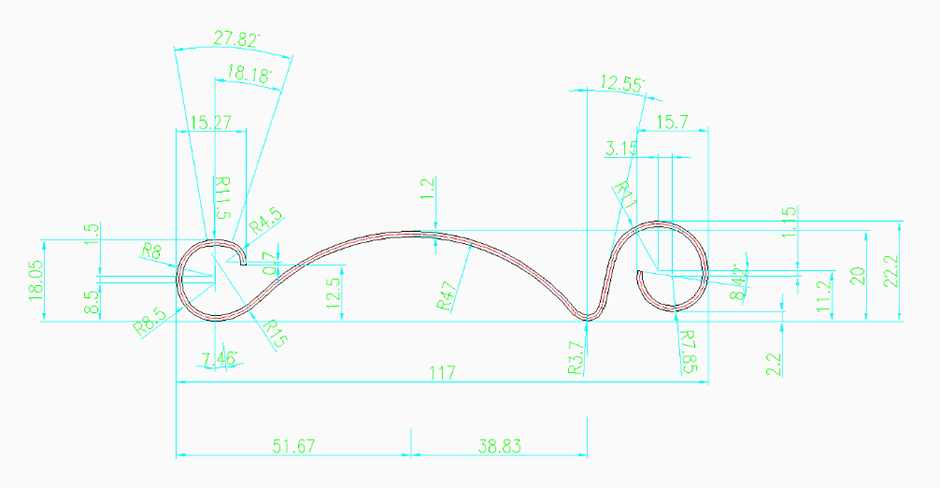

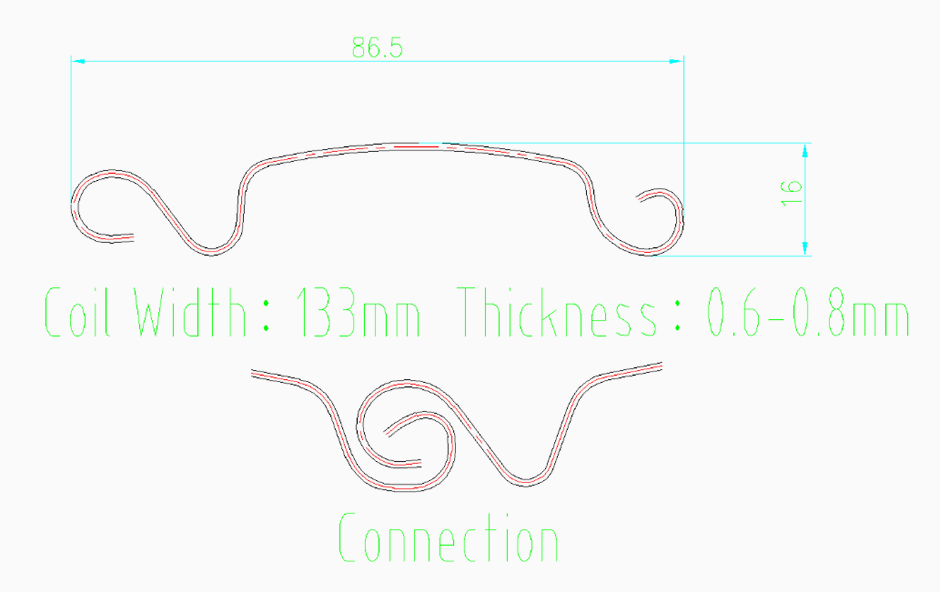

Profile:

Technical specification:

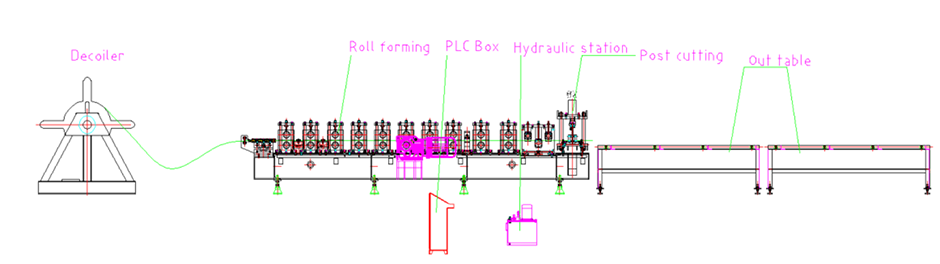

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table