We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for Factory Cheap Hot China Double Layer Metal Color Steel Roofing Sheet Roll Forming Machine, To much better expand industry, we sincerely invite ambitious individuals and corporations to hitch as an agent.

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for China Roof Panel Machine, corrugated roof panel, corrugated wall panel, Double Layer Roll Forming Machine, double layer roof forming machine, downspout pipe roll forming machine, downspout pipe round, downspout pipe square, gutter roll former, K span, K span MIC 120, ridge cap, ridge cap production line, Roll Forming Machine, roof panel, Roof Panel Machinery, roof tile, roof tile cold bending machine, Standing Seam Roll Forming Machine, trapezoidal roof panel forming machiney, trapezoidal wall panel roll forming machine, wall panel, Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

Description

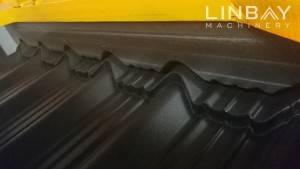

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

Technical Specifications

Flow Chart

Manual decoiler–feeding–roll forming–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table