Our enterprise insists all along the quality policy of “product high-quality is base of organization survival; customer gratification will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” and also the consistent purpose of “reputation very first, purchaser first” for Factory Customized China 1.5mm-2mm Galvanized Steel Hydraulic Punching Gearbox Drive Vineyard Post Roll Forming Machine, All items arrive with good quality and ideal after-sales solutions. Market-oriented and customer-oriented are what we now have been being immediately after. Sincerely sit up for Win-Win cooperation !

Our enterprise insists all along the quality policy of “product high-quality is base of organization survival; customer gratification will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” and also the consistent purpose of “reputation very first, purchaser first” for China Vineyard Trellis Post Roll Forming Machine, stake vineyard machine, steel vineyard post roll former, Vineyard post roll forming machine, Vineyard Trellis Post Making Machine, It is our customers’ satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Description

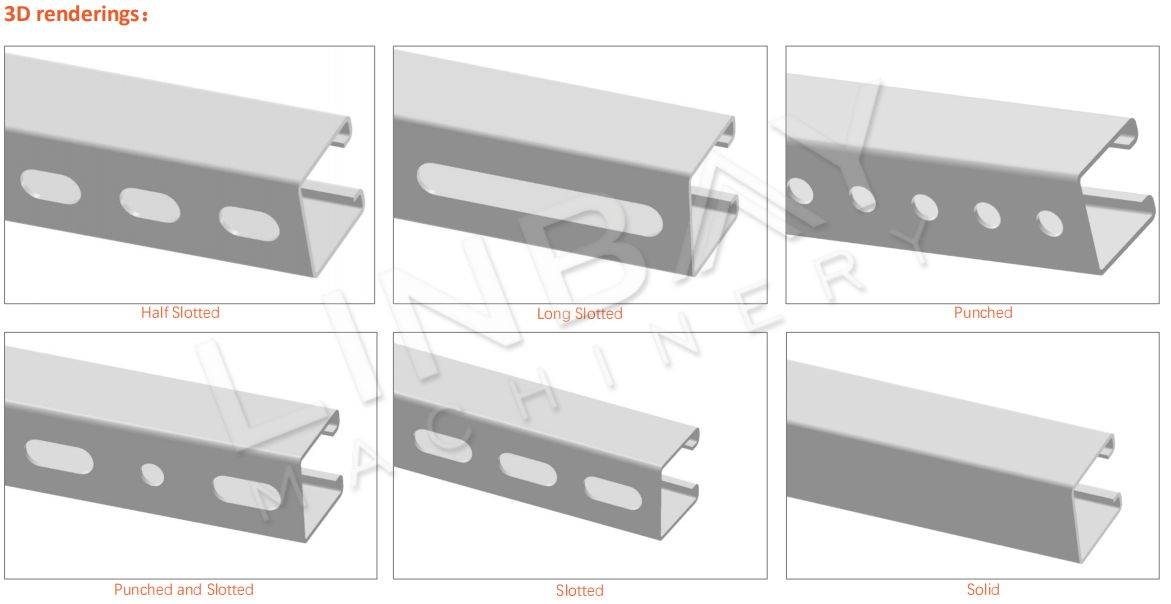

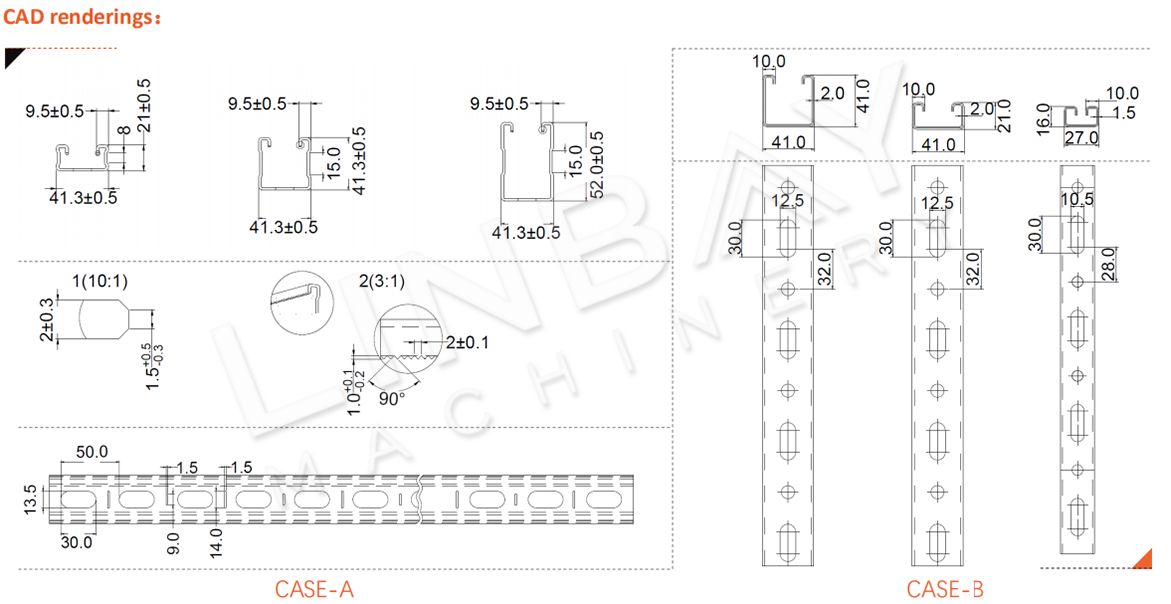

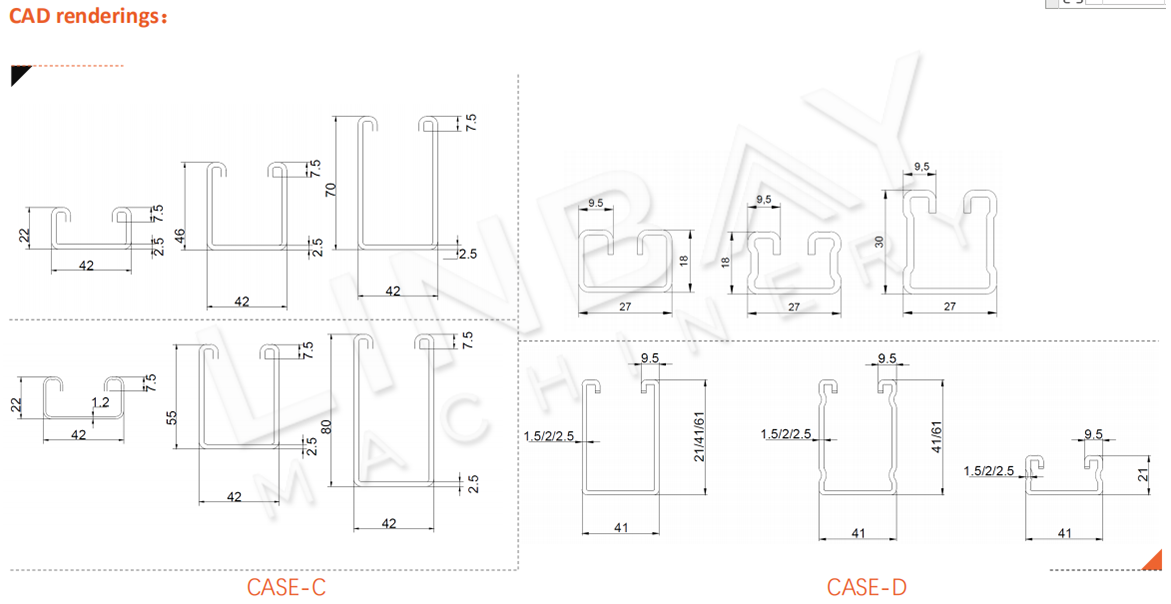

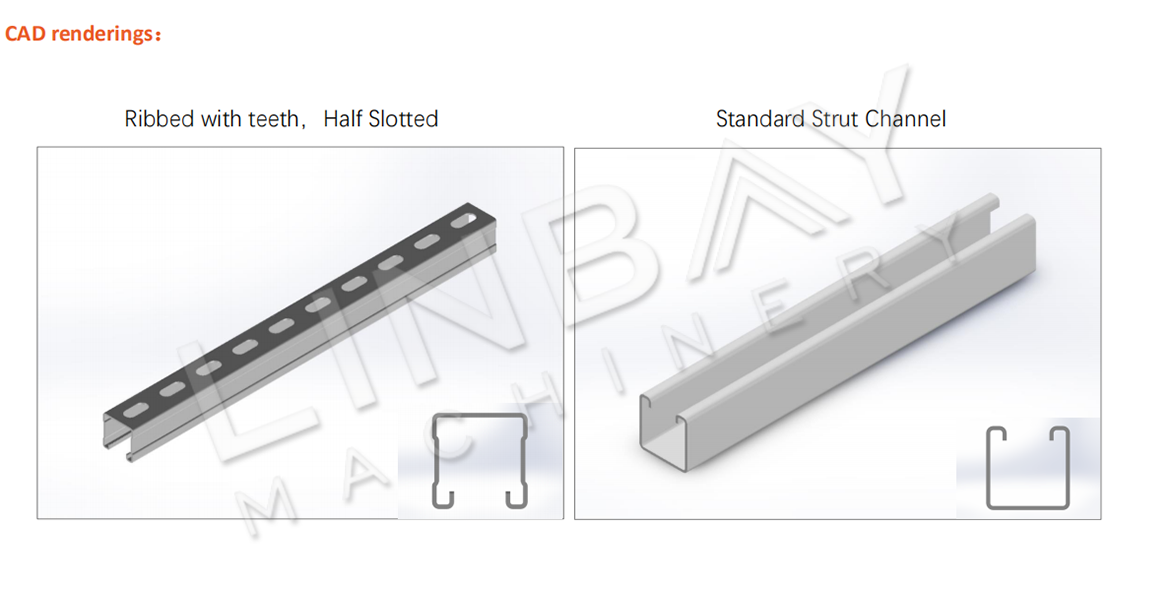

Strut channel roll forming machine has two main application: One is also called like seismic support roll forming machine or seismic channel roll forming machine, its product is used to mount, brace, support, and connect lightweight structural loads in building construction. Other is called solar rack roll forming machine or photovoltaic (PV) rack roll forming mahcine, its product is used in PV support bracket. Our strut channel roll forming machine is suitable to produce strut channels with 12 gauge ( 2.6mm ) or 14 gauge ( 1.9mm ) thick sheet metal ( normally range 2-2.5mm ), raw material could be Hot-rolled and cold rolled steel, Hot-dip galvanized sheet, PreGalvanized Steel, Mill ( Plain/Black ) Steel, Aluminum, Stainless Steel etc. And according to slot type, our machine could produce solid channel, slotted channel, half slotted channel, long slotted channel, punched channel, punched and slotted channel etc.

Application

Real Case A

Description:

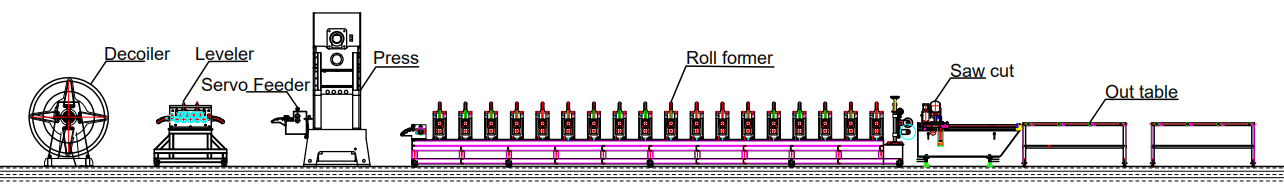

This strut channel production line is suitable for making many sizes of strut channels. In this case, we produce 5 different sizes totally. Therefore, we recommend burr-free saw cutting to reduce blade’s cost and changing blades time. If you want a non-stop cut, we could also turn this shear into flying one to increase working speed.

Real case B

Description:

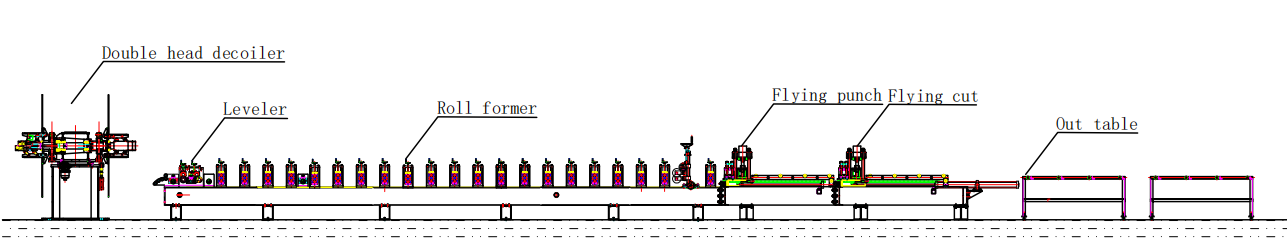

This strut channel production line is made for our Pakistani customer finished in 2018. This is a similar line of SAMCO, Canada using flying hydraulic punch and flying hydraulic cut, it means non-stop punch and non-stop cut. Normal working speed reach 20m/min. Also we suggest you a rotary punch, whose speed can realize 40m/min if you want a higher-yield production line.

Whole Production Line of Vinyard Post Roll Forming Machine

Technical Specifications

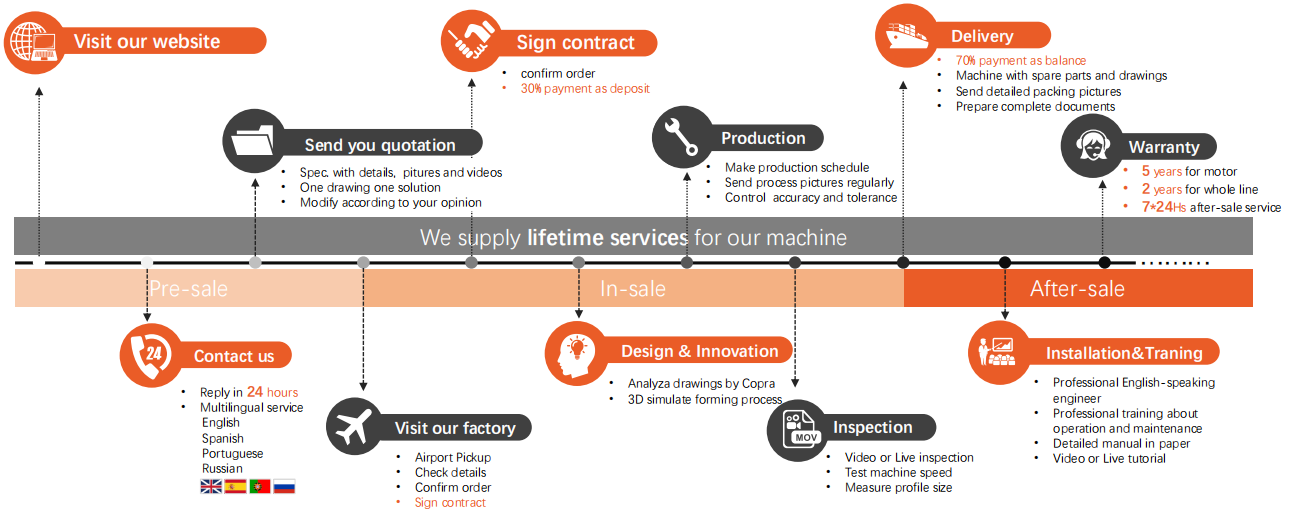

Purchase Service

Q&A

1. Q: What kinds of experience do you have in producing strut channel roll forming machine?

A: We have experience of exporting our strut channel roll formers to Pakistan, Mexico, Peru and Malaysia etc. We have produced solid channels, slotted channels, punched channels, standard channels etc. We are confident to solve your strut channel problem.

2. Q: How many sizes can be made in one machine?

A: One machine could produce one same width with different heights like 41×21, 41×41, 41×62, 41×82 or 27×18, 27×30.

3. Q: What is delivery time of strut channel machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. if you want a higher speed like 40m/min, we give you a solution with rotary punch system, which punch speed is up to 50m/min.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table