Usually customer-oriented, and it’s our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for Factory Customized China Highway Guardrail Roll Forming Machine Produce Highway Guardrail, Our merchandise are new and old clients consistent recognition and trust. We welcome new and aged consumers to call us for long run company relations, common advancement. Let’s speeding in the dark!

Usually customer-oriented, and it’s our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for Cable Tray Manufacturing Process, China highway guardrail roll forming machine, crash barrier roll forming machine, Guardrail Forming Machine, guardrail machine, guardrail machine manufacturers, guardrail machine suppliers, Guardrail Roll Forming Machine, highway crash forming machine, Highway fence roll forming machine, highway guardrail machine, Highway Guardrail Roll Forming Machine, Highway protection fence making machine, Highway safety fence machine, W-Beam machine, W-Beam roll forming machine, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our items or have an OEM order to fulfill, remember to feel free to contact us now. Working with us will save you money and time.

Description:

This Highway Guardrail Roll Forming Machine can be designed as two waves or three waves profiles in one machine just need to add some stations at the end of the machine. We adopt the universal joint driving system. The Max.thickness can reach at 4.0mm.

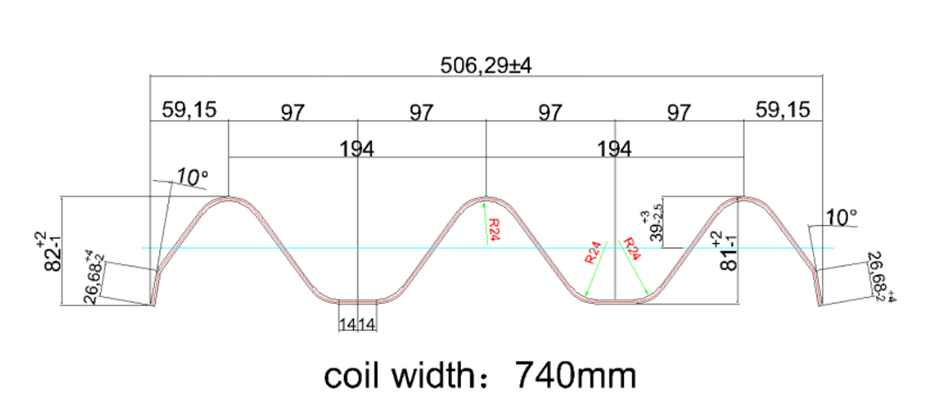

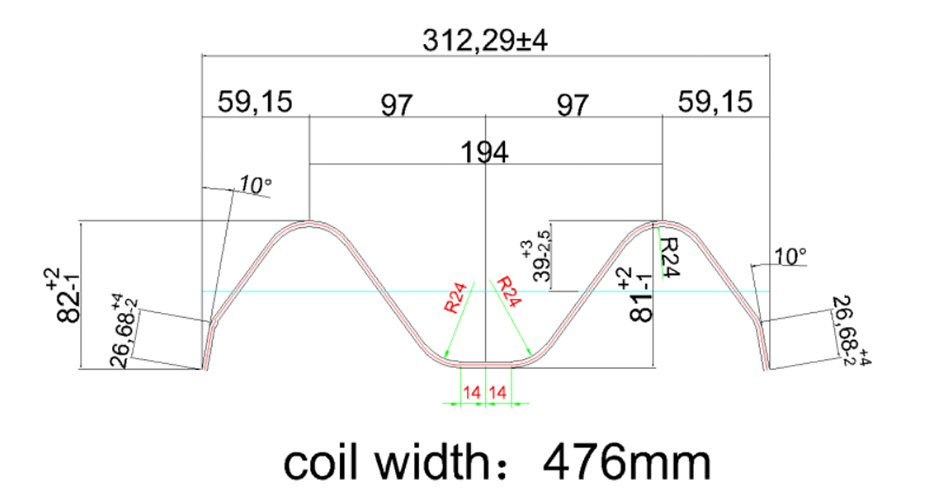

Profile:

Technical specification:

|

Two Waves/Three Waves Highway Guardrail Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):2-4 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

15 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Gearbox drive | Chain drive |

|

9 |

Rollers’ materail |

Cr12 | GCr15 or #45 Steel |

|

10 |

Station structure |

Forged Iron station | Wall panel stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

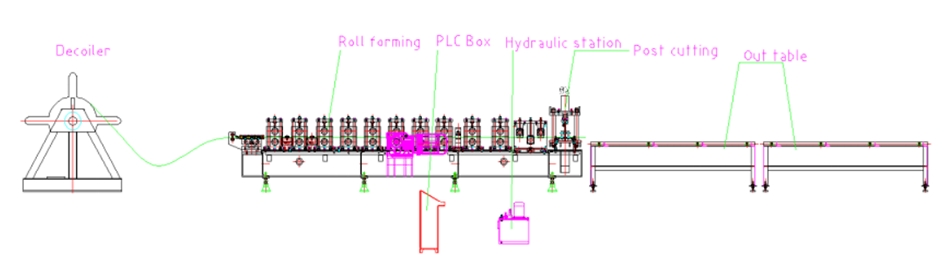

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Factory best selling China Maquinas PARA Hacer ...

-

New Arrival China China Maquinas PARA Doblar Ca...

-

Wholesale OEM/ODM China High Precision C Solar ...

-

PriceList for Ibr Panel Double Layer Roll Formi...

-

China Supplier China Yufa Hydraulic Cutting Aut...

-

China Wholesale China Perfiladora De Chapa Acan...