We’re commitment to offer you the competitive price ,remarkable products excellent, also as fast delivery for Factory For China Excellent Quality Highway U post Roll Forming Machine, We’ve been in search of for extensive cooperation with truthful shoppers, accomplishing a completely new cause of glory with buyers and strategic companions.

We’re commitment to offer you the competitive price ,remarkable products excellent, also as fast delivery for China Highway Beam Roll Forming Machine, crash barrier roll forming machine, Guardrail Forming Machine, guardrail machine, guardrail machine manufacturers, guardrail machine suppliers, Guardrail Roll Forming Machine, highway guardrail machine, Highway Guardrail Roll Forming Machine, Highway protection fence making machine, Highway safety fence machine, W-Beam machine, W-Beam roll forming machine, our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

Description

We had experience of Russian type Guardrail, there are four lines totally:① two wave guardrail roll forming machine, ② U post roll forming machine,③ connection punching line and ④end wind punching line.

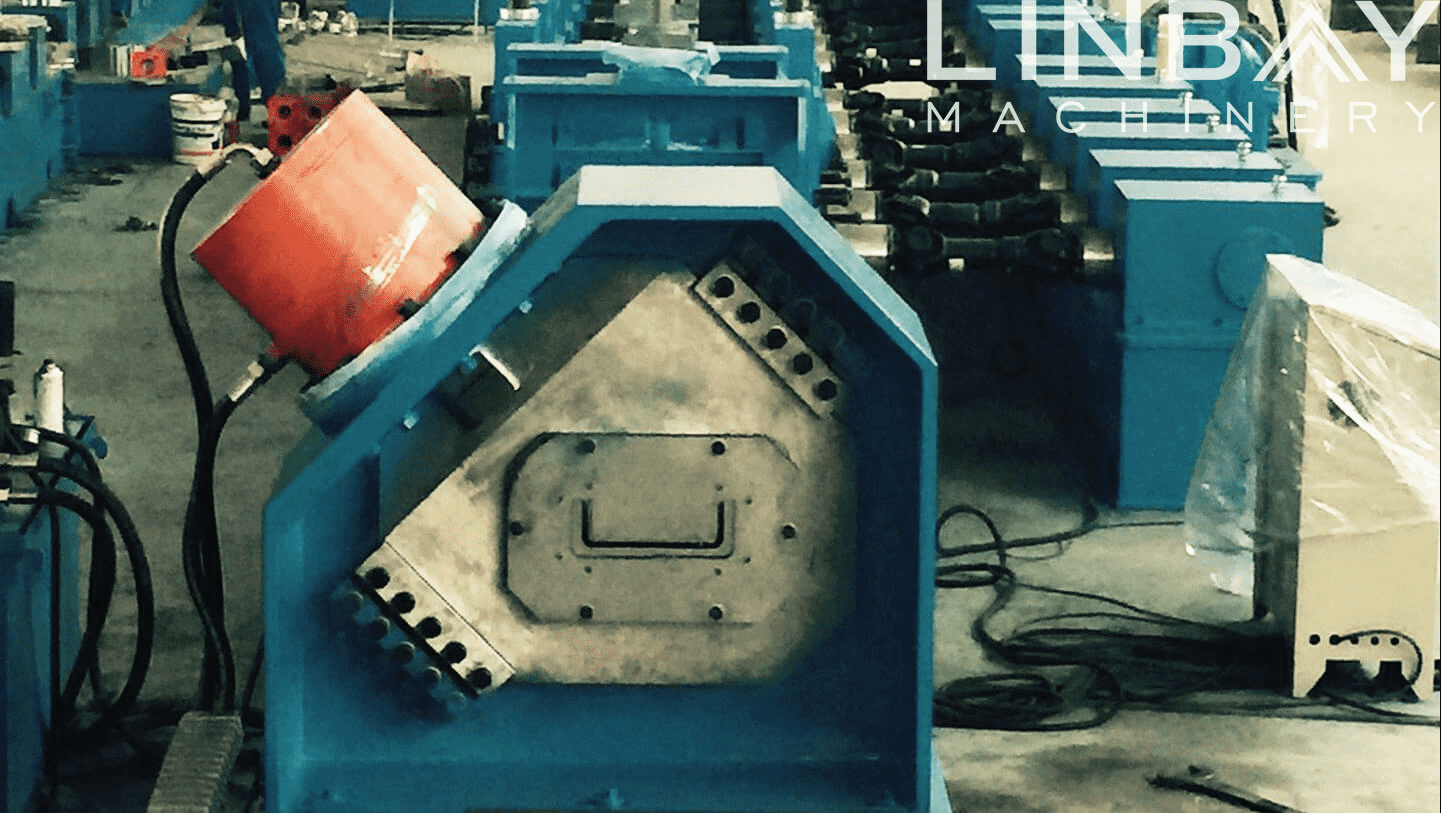

This U Roll Forming Machine can be designed for thickness 4-5mm, it is widely used as post of guardrail. We use forged iron stands(see picture) and gearbox driving to make sure this machine can longly work in a stable situation.

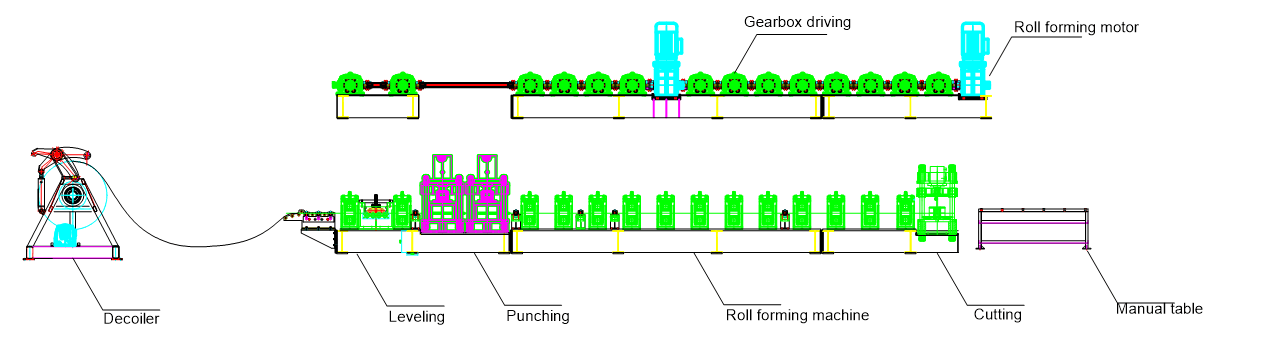

The flow chart of U post roll forming machine:

Hydraulic decoiler-Leveling-Punching-Roll forming machine-Cutting-Out table

Technical Specifications

|

Two Waves/Three Waves Highway Guardrail Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):4-5 |

|||

|

Yield strength: 250 – 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

15 |

Or according to your requirement |

|

3 |

Forming station |

10-12 |

According to your profile |

|

4 |

Decoiler |

Hydraulic decoiler |

|

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Siemens |

Panasonic |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

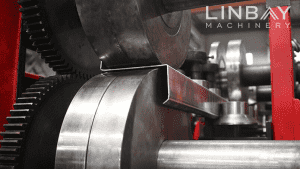

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

Cr12 |

GCr15 or #45 Steel |

|

10 |

Station structure |

Forged Iron station |

Wall panel station Or torri stand structure |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

More Pictures

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table