We believe that extended time period partnership can be a result of high quality, worth added service, wealthy knowledge and personal contact for Factory Price Galvanized Ridge Roofing Sheet/cap Gutter Roll Forming Machine, To significantly improve our assistance quality, our company imports a large number of international advanced devices. Welcome clients from your home and abroad to simply call and inquire!

We believe that extended time period partnership can be a result of high quality, worth added service, wealthy knowledge and personal contact for Galvanized Ridge Roofing Sheet/cap Gutter Roll Forming Machine, Roof Panel Ridge Cap Cold Roll Forming Machine, Roof Panel Ridge Cap Tile Machine, Our company sticks to the principle of “high quality, reasonable price and timely delivery”. We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent products and services. Welcome to join us!

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

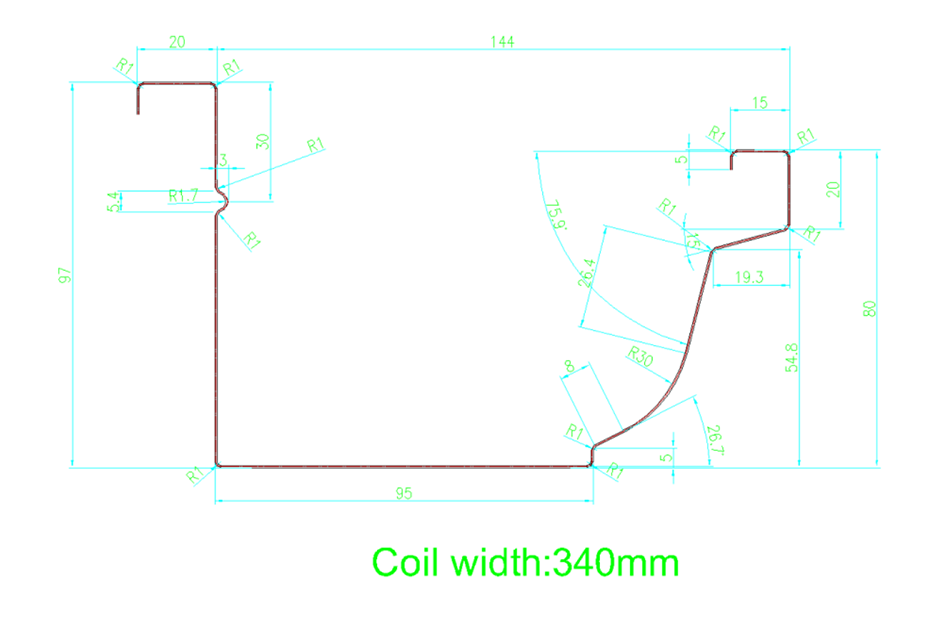

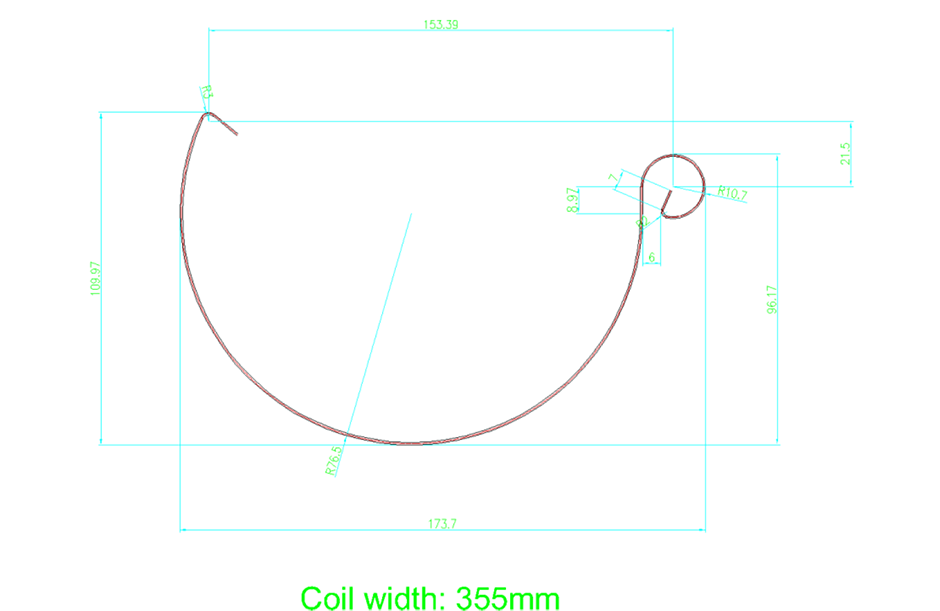

Profile:

Technical specification:

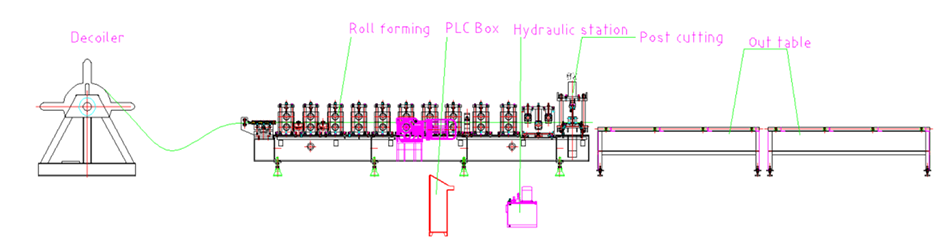

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table