Factory supplied Shutter Door Machine - Rolling Shutter Slat roll forming machine – Linbay Machinery Detail:

Description:

Roller Shutter Door Roll Forming Machine produce stainless steel rolling shutter doors and color steel rolling shutter doors. We use punching press to make different hollow-carved designs. If you ask, we can also produce PU Rolling Shutter Door Roll Forming Machine, which machine can make fire resistance and thermal insulation rolling shutter doors.

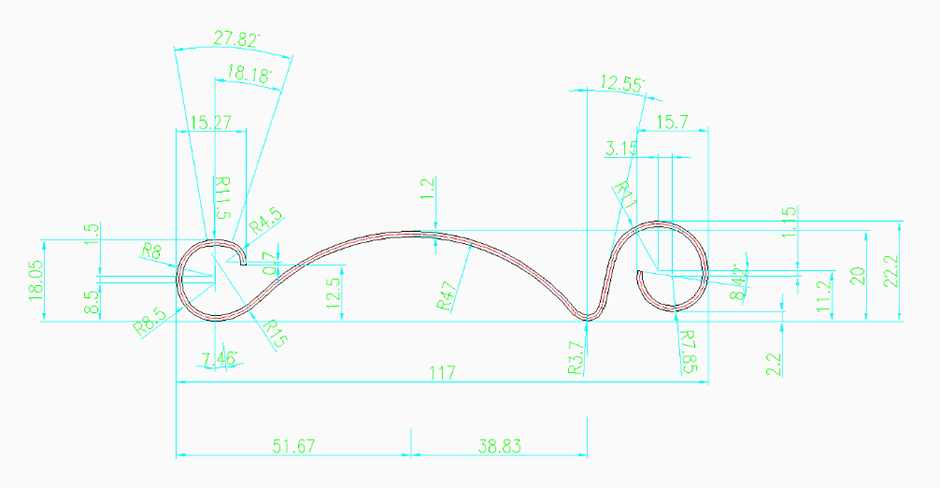

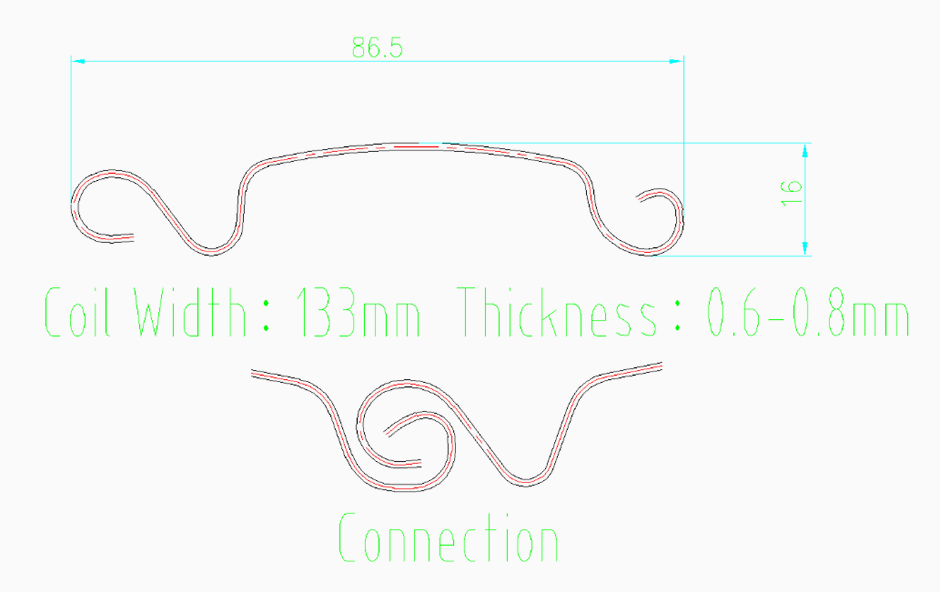

Profile:

Technical specification:

|

Roller Shutter Door roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.0-2.0 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

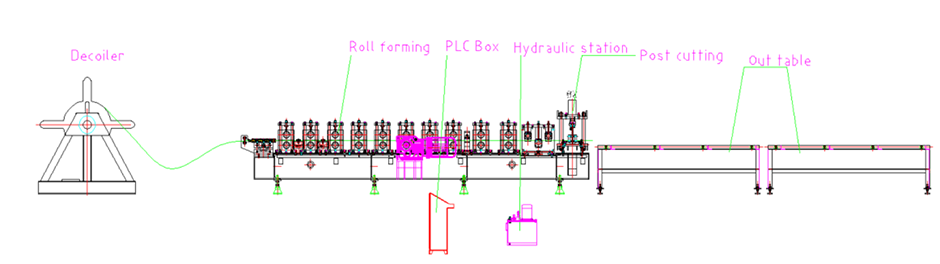

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Understanding Roll Forming Machines

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Factory supplied Shutter Door Machine - Rolling Shutter Slat roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Colombia, United Kingdom, Iraq, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

Send your message to us:

-

Wholesale ODM Metal Roll Forming Machine - Dow...

-

Best Price for Galvanized Cold Roll Forming Mac...

-

China wholesale Corrugated Machine Price - Cab...

-

ODM Manufacturer Floor Machine - Roofing Tile ...

-

Online Exporter Cold Rolling Steel Bar Making M...

-

Wholesale OEM/ODM Gutter Making Roll Forming Ma...