VIDEO

Perfil

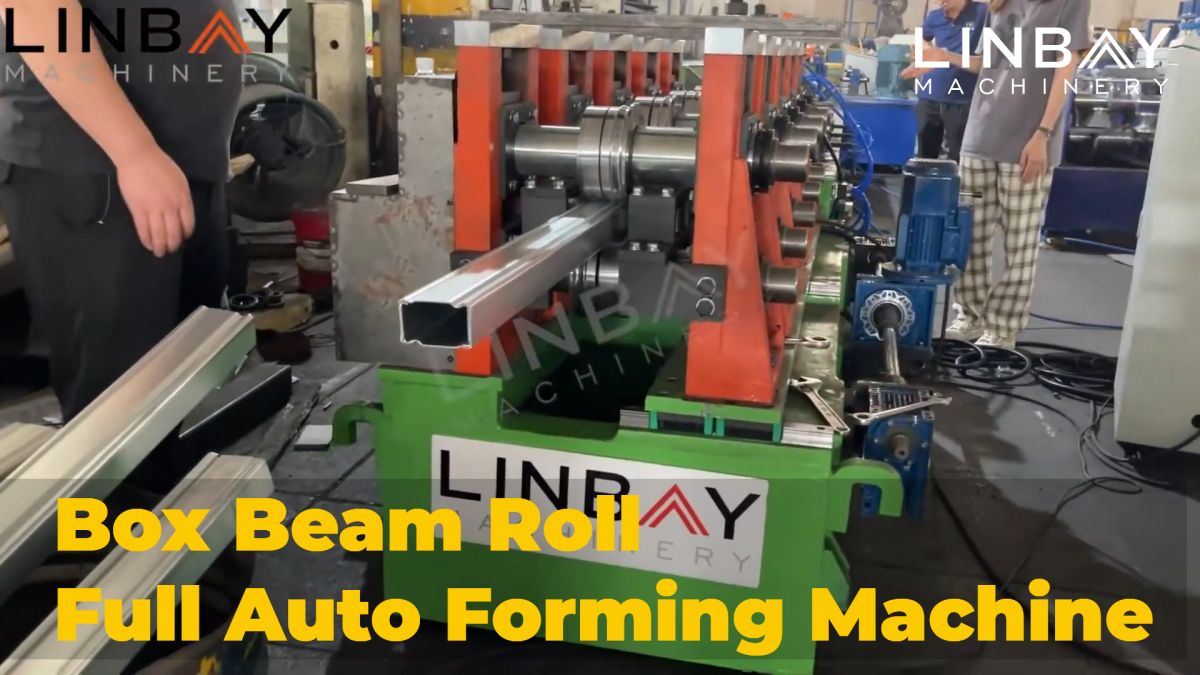

The box beam stands as a robust option tailored for heavy-duty applications. Specifically, we present a two-piece type box beam for your consideration. Typically forged from cold-rolled or hot-rolled steel with a thickness ranging from 1.5 to 2mm, it undergoes precise roll forming before being coated to ensure a balance of visual appeal and enduring strength. The assembly involves securely joining two pieces of formed C-shape steel profiles, resulting in a sturdy tube structure. For the production of box beams, the cold roll forming machine emerges as the preferred choice, offering efficiency and precision.

Real case-Main Techinical Parameters

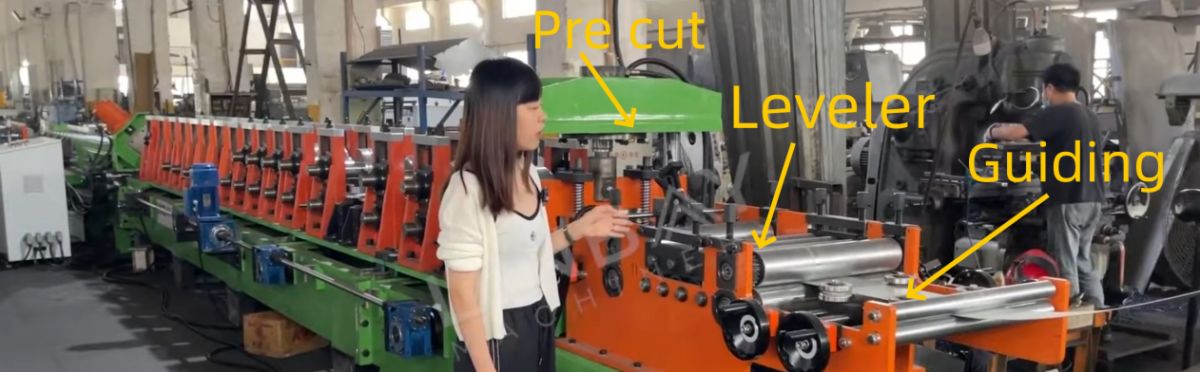

Guiding rollers are pivotal in upholding alignment between the steel coil and the machinery, effectively averting distortion of the box beam. They also play a vital role in the forming process, preventing rebound deformation of the steel coil. The straightness of the box beam holds considerable sway over product quality and the load-bearing capabilities of the entire shelf. Strategically positioned along the forming line, guiding rollers ensure meticulous alignment. Measurements of each guiding roller's distance to the edge are meticulously documented in the manual, enabling seamless adjustments based on this data, even in the event of minor displacements during transportation or production.

Leveler

Following the preceding stage, the steel coil progresses to the leveling process. Here, the leveling machine diligently eliminates any curvature present in the steel coil, thereby improving its flatness and parallelism, consequently enhancing the quality of the final product - the box beam. Equipped with 2 upper and 3 lower leveling rolls, the leveling machine ensures meticulous precision in preparing the steel coil for subsequent manufacturing steps.

Hydraulic Pre-Cut

This production line incorporates a hydraulic pre-cutting device, simplifying the replacement of steel coils with varying widths and thicknesses, while simultaneously minimizing coil waste.

Roll Forming Machine

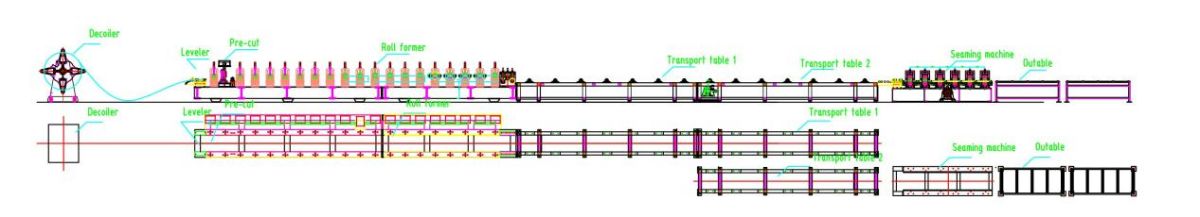

Flow chart

Manual decoiler--Guiding--Leveler--Hydraulic pre cut--Roll forming machine--Flying hydraulic cut--Platform--Seaming machine--Out table

Main Techinical Parameters

1.Line speed: 0-4 m/min, adjustable

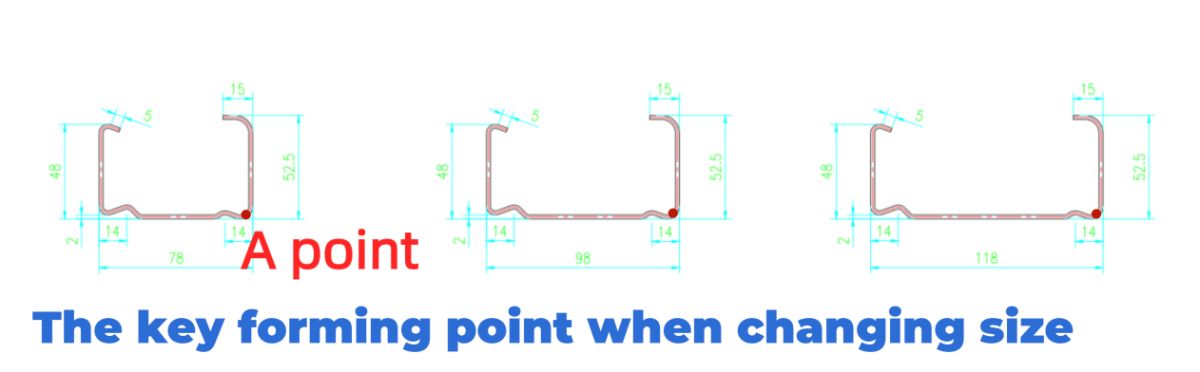

2.Profiles: Multiple sizes-same height of 50mm, and different width of 80, 100, 120mm

3.Material thickness:1.5-2mm

4.Suitable material:Hot rolled steel, cold rolled steel, galvanized steel

5.Roll forming machine: Cast-iron stru

cture and chain driving system.

6.No. Of forming station: 18

7.Cutting system: Hydraulic cutting,roll former doesn’t stop when cutting.

8.Changing size: Automatically.

9.PLC cabinet: Siemens system.

Real case-Description

Manual Decoiler

The manual decoiler is outfitted with a braking system meticulously engineered to regulate the tension of the unwinding roll and ensure a smooth unwinding process. To mitigate the risk of sudden recoil, particularly for steel coils exceeding 1.5mm in thickness, a press arm is employed to securely hold the steel coil in place. Furthermore, steel protection leaves are strategically installed to prevent coil slippage during unwinding. This thoughtful design not only enhances safety but also offers high cost-effectiveness, ensuring reliable and efficient operation.

In this scenario, a manual decoiler without its own power source is employed. For more substantial production speed requirements, we offer an optional hydraulic decoiler powered by a hydraulic station.

Guiding

At the heart of the entire production line lies the roll forming machine, an indispensable component. Constructed from a solid piece of cast iron, this machine boasts a robust structure and is driven by a reliable chain system. Its versatility enables the production of various sizes with consistent height. Operators effortlessly input planned dimensions on the PLC control screen, triggering automatic adjustments of forming stations to precise positions. Typically, experienced workers require approximately 60 minutes to execute the complete dimension-changing process, encompassing both the automatic movement of forming stations and the manual replacement of the steel coil.

The A point acts as a pivotal forming point for width adjustments. As roll forming stations move along the rails, they dynamically shift the position of this critical forming point, enabling the production of box beams with varying widths.

For the material of forming rollers, Gcr15 is chosen—a high-carbon chromium-bearing steel renowned for its exceptional hardness and wear resistance. These rollers undergo chrome-plating to enhance their longevity, while the shafts, crafted from 40Cr material, undergo heat treatment for added durability.

Flying Hydraulic Cut

After undergoing the roll forming process, the steel coil gradually conforms to a C-shaped profile. It is then precisely cut to the required length by a hydraulic cutting machine, maintaining a cutting length error within 1mm. This cutting process efficiently minimizes steel coil wastage and synchronizes with the production speed of the roll forming machine, ensuring seamless and uninterrupted operation.

Platform

The initial C-profile is conveyed to the upper platform and then pushed onto the lower platform. Subsequently, the second C-profile is carefully pushed onto the middle slope, where a flipping device rotates it. This action aligns and neatly stacks the two C-profiles vertically.

Guiding rollers ensure alignment of the two C-profiles, and pneumatic push rods push them into the seaming machine.

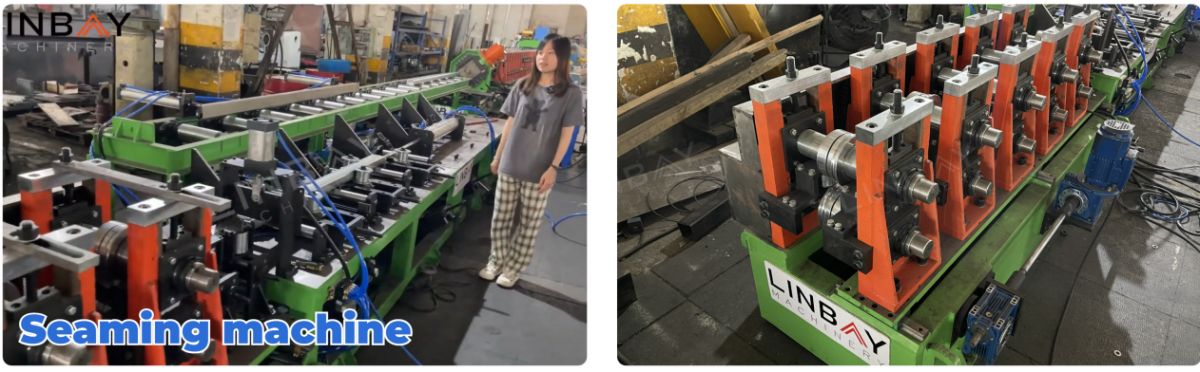

Seaming machine

The seaming machine mirrors the structure of the roll forming machine, boasting a cast-iron structure and chain driving system. It autonomously adjusts the seaming station positions according to the box beam's width. This innovation eliminates the need for a welder, as traditionally, a worker was required to weld the two C-profiles into a box beam post-roll forming.

Encoder & PLC

The roll forming machine is equipped with a Japanese Koyo encoder, which accurately converts coil length into electrical signals for the PLC control cabinet. This precision guarantees cutting errors are limited to 1mm, ensuring high-quality box beams and reducing waste. Operators can control production speed, set dimensions, cutting length, and more via the PLC screen. The cabinet also stores commonly used parameters and offers protection against overload, short circuit, and phase loss. Language settings on the PLC screen can be customized to suit customer preferences.

Hydraulic Station

Our hydraulic station, equipped with cooling electric fans, efficiently dissipates heat, ensuring extended and reliable operation with a low failure rate.

Warranty

Upon shipment, the nameplate clearly indicates the delivery date, providing a two-year guarantee for the entire production line and an impressive five-year warranty for rollers and shafts.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table