With a positive and progressive attitude to customer’s curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of High Performance Superior Quality Roll Shutter Door Roll Forming Machine, We would like to take this opportunity to establish long-term business relationships with clients from all over the world.

With a positive and progressive attitude to customer’s curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of popular rolling shutter slat roll forming machine, price rolling shutter slat roll former, rolling shutter slat making machine China, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

Description:

Roller Shutter Door Roll Forming Machine produce stainless steel rolling shutter doors and color steel rolling shutter doors. We use punching press to make different hollow-carved designs. If you ask, we can also produce PU Rolling Shutter Door Roll Forming Machine, which machine can make fire resistance and thermal insulation rolling shutter doors.

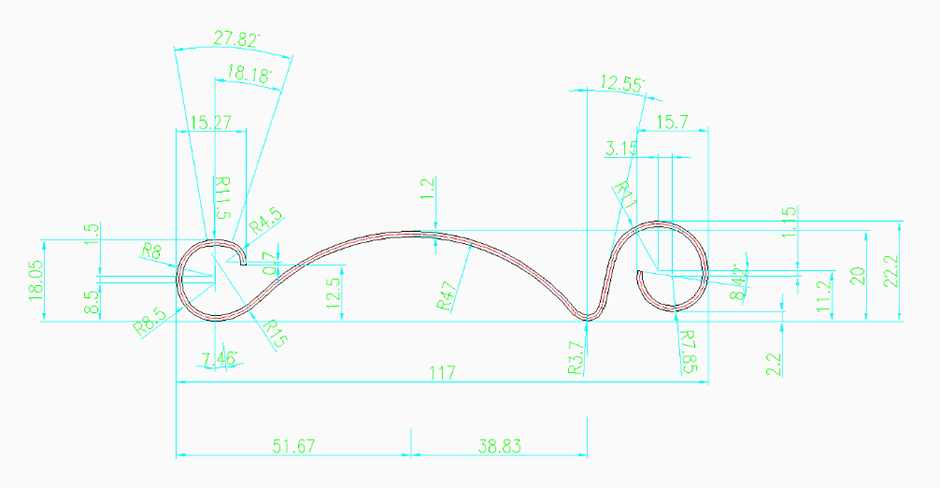

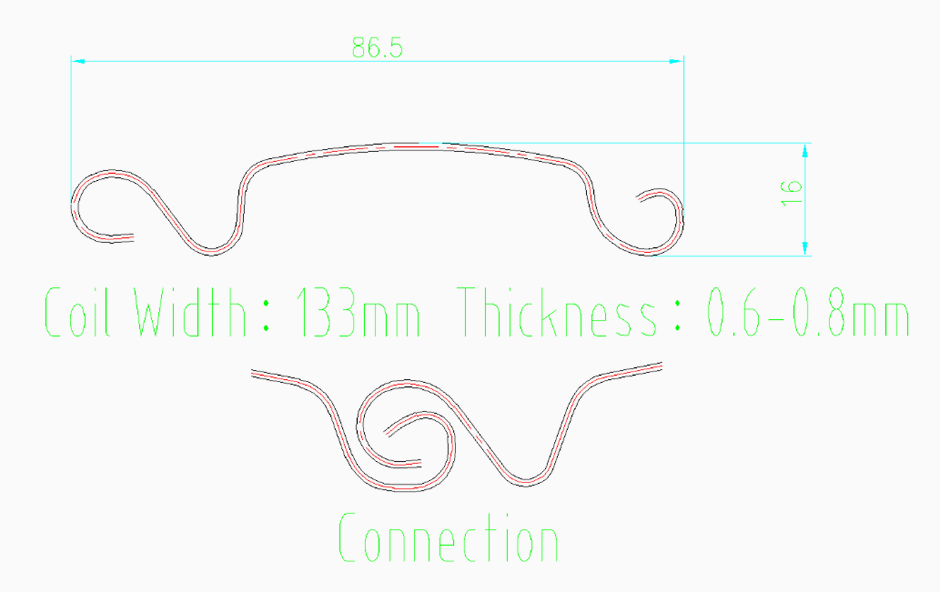

Profile:

Technical specification:

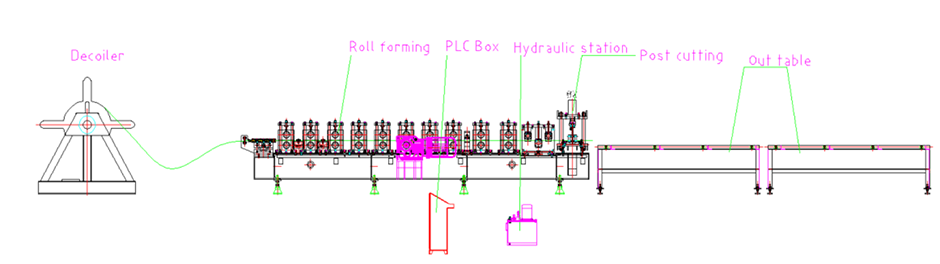

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table