We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for High Quality China Hydraulic Cutting Type Dual Solar Panel Bracket Roll Forming Machine, Adhering towards the business philosophy of ‘customer 1st, forge ahead’, we sincerely welcome clients from at home and abroad to cooperate with us supply you with very best services!

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for China Building Machine, Cold Bending Machine, Construction Machinery, double row roll forming machine, galvanized forming machinery, metal steel roll forming machine, roll former, Roll Forming Machine, roll forming machine china, roll making machine, solar rack, solar rack former, solar rack forming machine, Solar Rack Roll Forming Machine, solar racking, solar racking forming machinery, solar racking manufacturer, solar racking solutions, solar racking suppliers, solar racking system, steel roll making machine, “Create Values,Serving Customer!” is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

Description

Strut channel roll forming machine is also called like seismic support roll forming machine or seismic channel roll forming machine, its product is used to mount, brace, support, and connect lightweight structural loads in building construction. Our strut channel roll forming machine is suitable to produce strut channels with 12 gauge(2.6mm) or 14 gauge(1.9mm) thick sheet metal (normally range 2-2.5mm), raw material could be Hot-rolled and cold rolled steel, Hot-dip galvanized sheet, Pre-Galvanized Steel, Mill(Plain/Black) Steel, Aluminum, Stainless Steel etc. And according to slot type, our machine could produce solid channel, slotted channel, half slotted channel, long slotted channel, punched channel, punched and slotted channel etc.

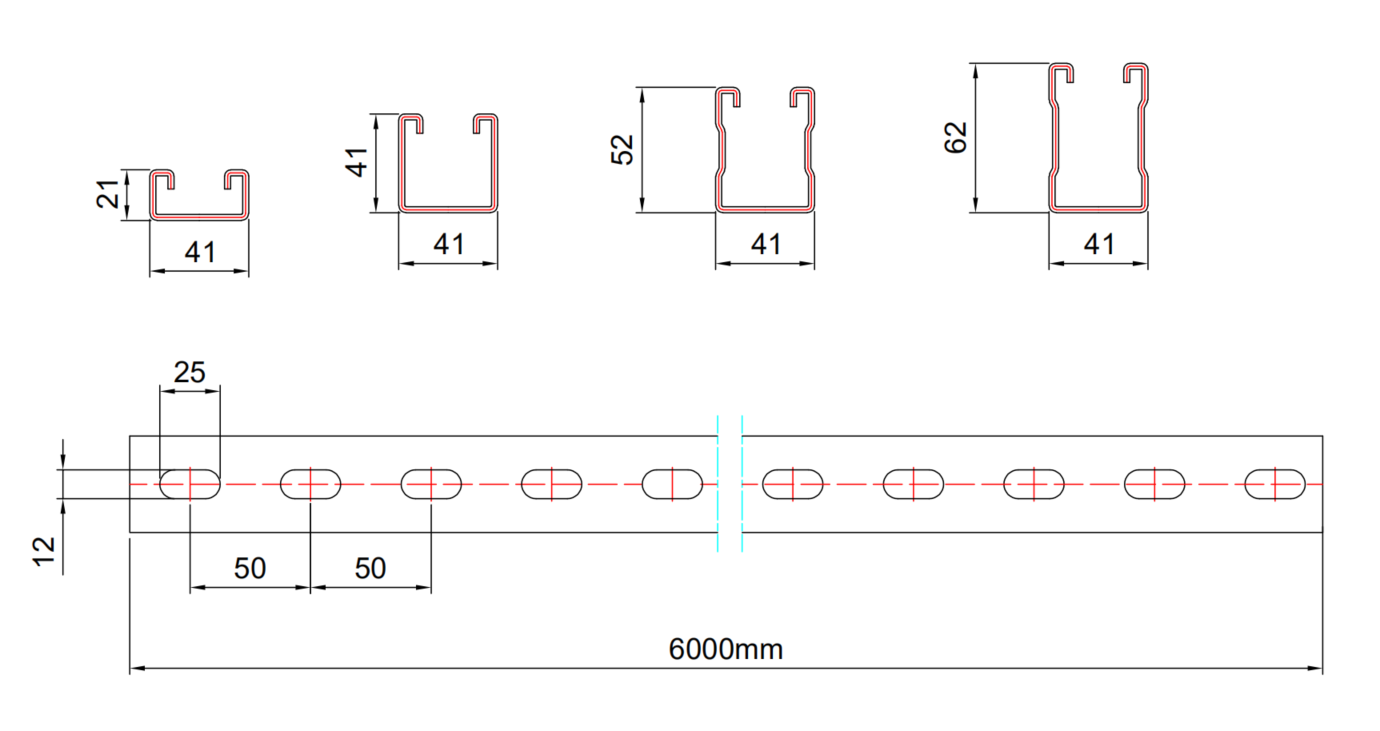

Linbay has many experience at solar photovoltaic stents roll forming machine. We exported to Saudi Arabia, Turkey, Iraq, India, Kuwait, Qatar, Pakistan, Argentina etc. We have made the strut channel profile, and American standard profile as well. The most popular size of strut channel profile is 40*21, 41*41, 41*62, and our roll forming machine could produce 3-5 sizes(eg: 41×21, 41×41, 41×62) in one machine (by manually change spacers), the working speed can reach 16m/min.

Now we have two workshops producing solar photovoltaic stents and we export it to USA. If you come to visit us, we would like to show you the producing line.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

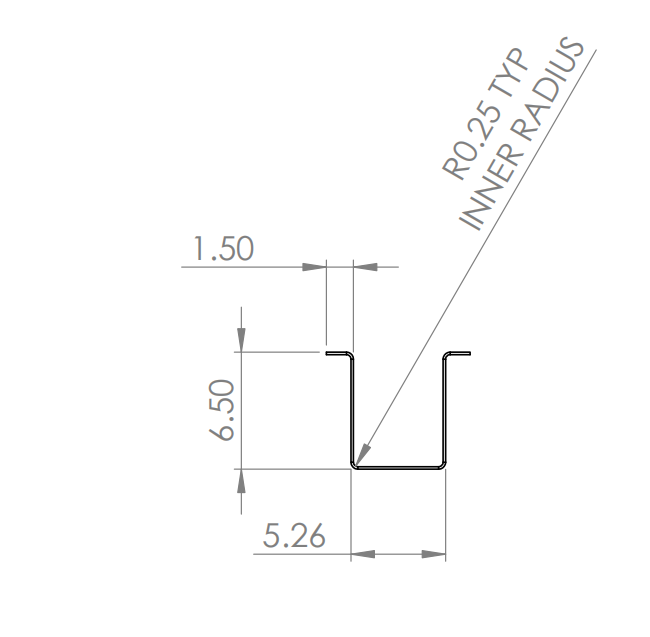

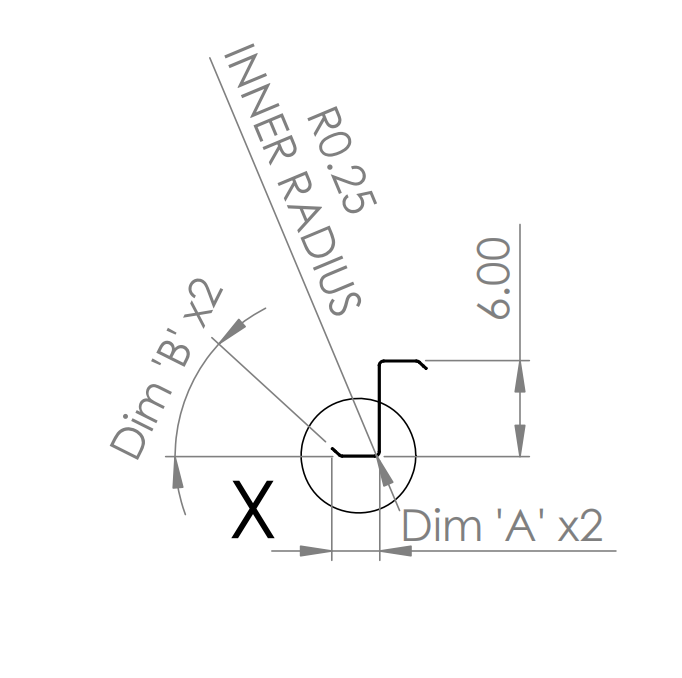

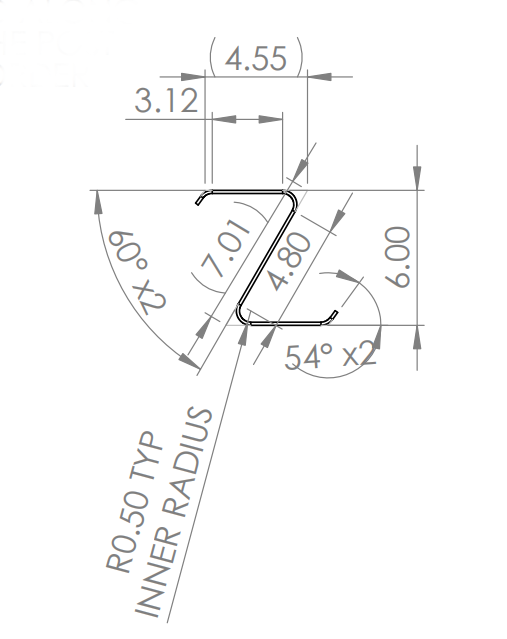

Profile drawings

Real Case A

Description:

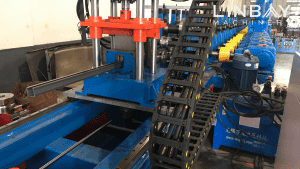

This solar photovoltaic stents roll forming production line is very efficient and higher yield. In this case, we produce 5 different sizes totally and production speed is up to 16m/min. Besides, we recommend burr-free saw cutting to reduce steel wastage and manufacturing cost, reasonable range of burr improves the quality of profile and price, bringing greater benefits to customers. We also adopts the flying saw cutting system to optimize production. This is the best configuration of solar photovoltaic stents roll forming machine.

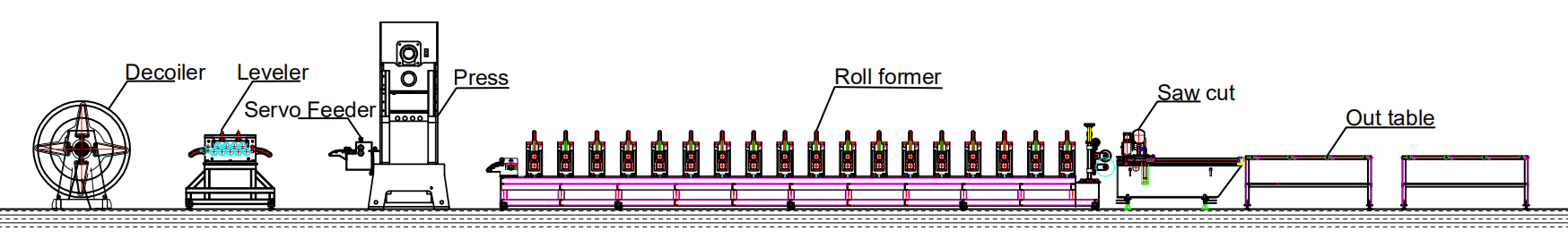

Flow Chart::

Hydraulic decoiler-Levler-servo feeder-Press- Roll former-Flying saw cut-Out table

Profile drawings

Technical specification

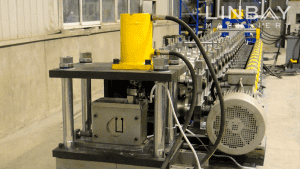

Machine Pictures

Q&A

1. Q: What kinds of experience do you have in producing solar photovoltaic stents roll forming machine?

A: We have experience of exporting our solar photovoltaic stents roll formers to Saudi Arabia, Turkey, Iraq, India, Kuwait, Qatar, Pakistan, Argentina etc. We have produced solid channels, slotted channels, punched channels, standard channels, American standard racks etc. We are confident to solve your solar racking problem.

2. Q: How many sizes can be made in one machine?

A: One machine could produce one same width with different heights like 41×21, 41×41, 41×62, 41×82 or 27×18, 27×30.

3. Q: What is delivery time of solar photovoltaic roll forming machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. if you want a higher speed like 40m/min, we give you a solution with rotary punch system, which punch speed is up to 50m/min.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table