Description

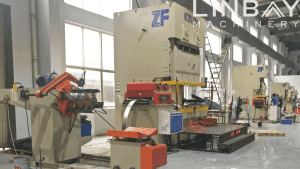

We have experience of exporting our guardrail roll formers to Russia, Saudi Arabia, Turkey, Indonesia etc. And we have a Chinese government project. We provide machine and guardrails to our government. You could see our producing line in new factory, if you visit us.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

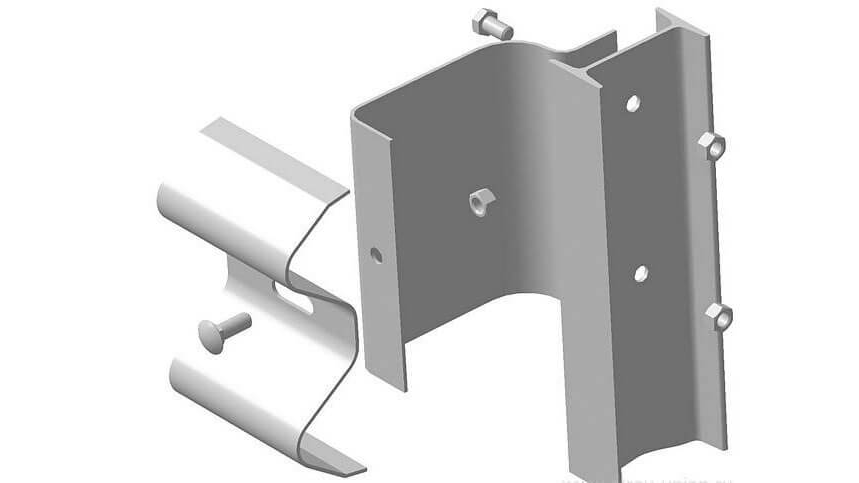

Real Case A

We had experience of Russian type Guardrail, there are four lines totally:① two wave guardrail roll forming machine, ② U post roll forming machine,③ connection punching line and ④end wind punching line.

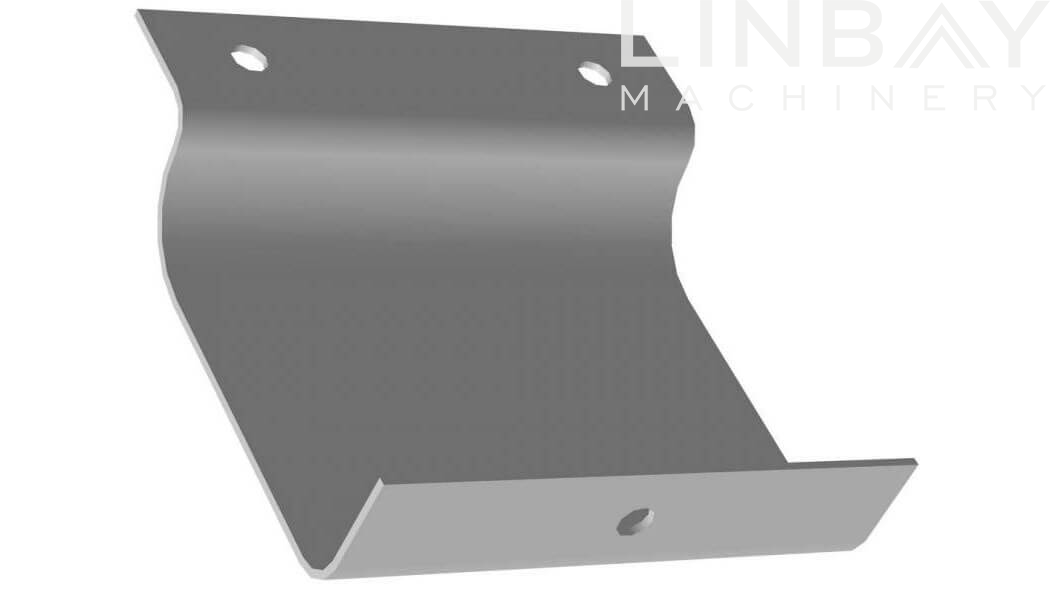

This connection is very poplar in Russia to protect the guardrail and car drivers, it works as a buffer strip when there is a impact. The normal thickness is around 4mm. So we adopt forged iron stands and gearbox driving to make sure this machine can work longly in a stable situation in the following 20 years. The punching speed can up to 70 times/minute.

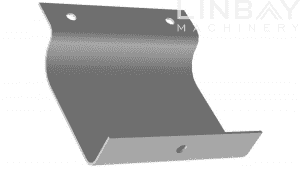

Profile drawing

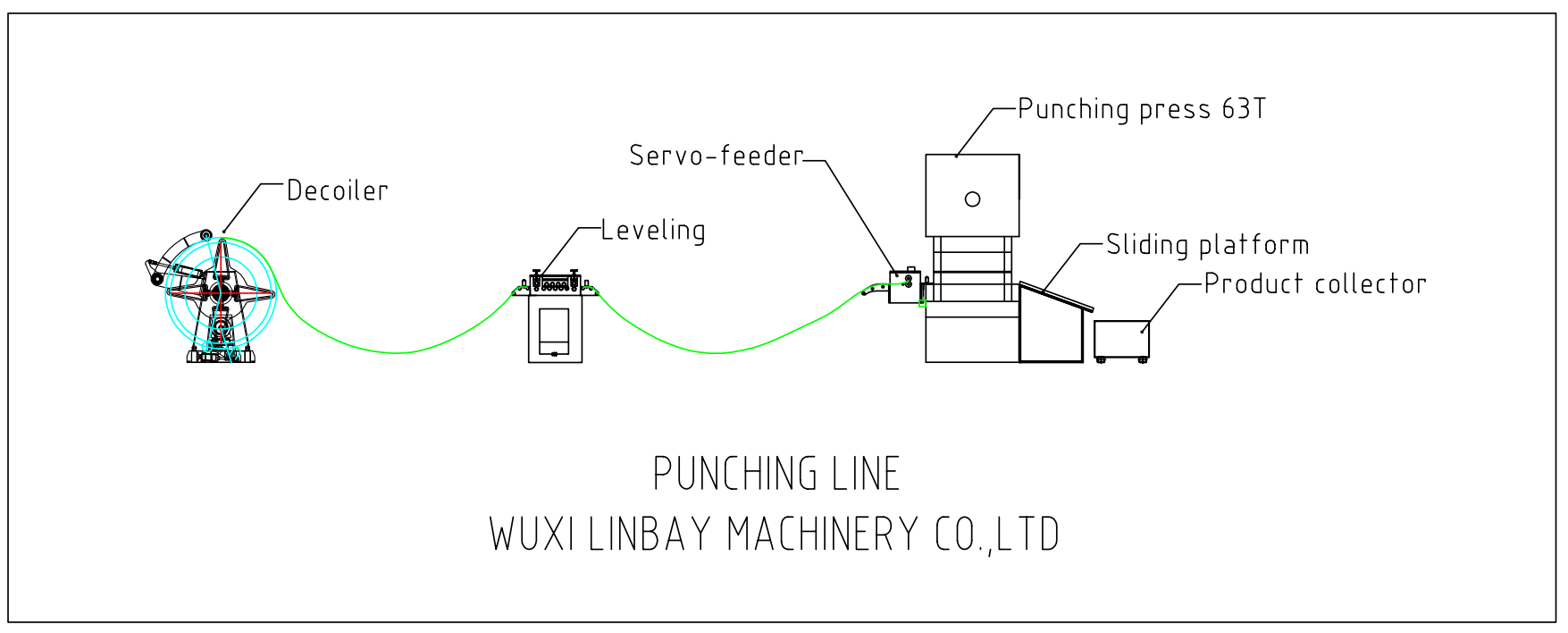

Flow chart:

Hydraulic decoiler-Leveling-Servo feeder-Punching-Collector box

- Hydraulic power of decoiler: 4KW

- Loading power of decoiler:5tons

- Power of leveling:2.2KW

- No. of leveling roller: 7

- Power of Servo feeder: 1.8KW

- Brand of inverter: YASKAWA

- Brand of PLC:Siemens

- Power of punching press: 63Tons

- Speed of punching press:70 pcs/min

Real Case B

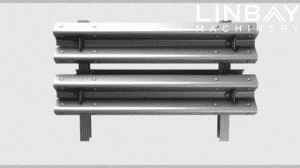

In Saudi Arabia, Dubai and many other Middle East countries uses the following type of highway guardrail system:

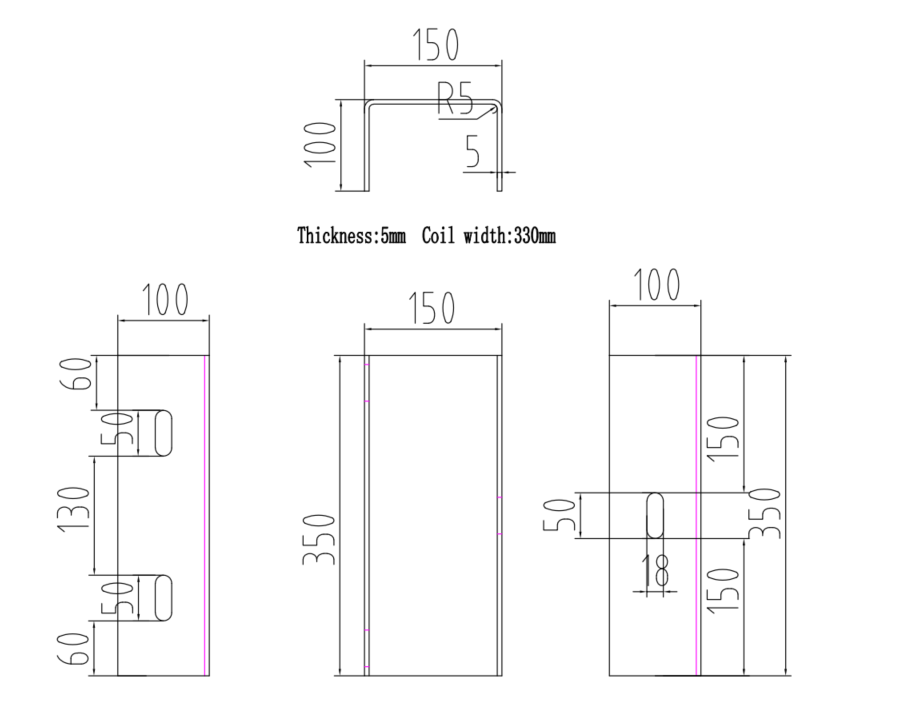

AASHTO M180 W beam 2.7mm thickness 4130mm long+guardrail spacer block 5mm thickness 350mm long+ guardrail post 5mm thickness 1830mm long

This space block is made by post roll forming machine, they are same profile, only length different.

Profile drawing:

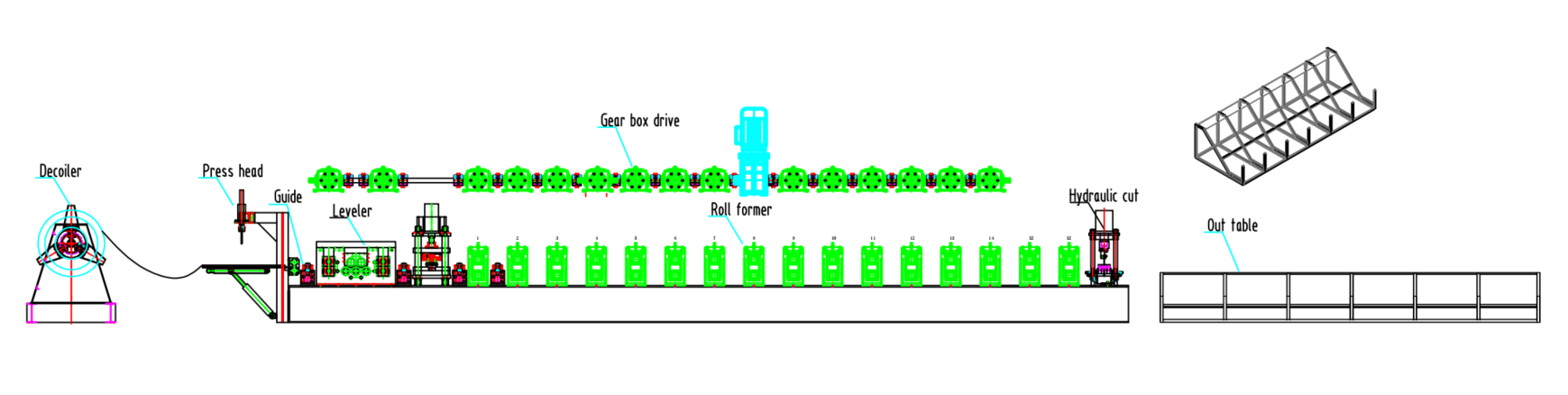

Flow chart:

Technical Specifications

More Pictures

Q&A

1. Q: What kinds of experience do you have in producing highway guardrail roll forming machine?

A: We have experience of exporting our highway guardrail roll formers to Russia, Saudi Arabia, Turkey, Indonesia etc. We have produced AASHTO M180--American Guardrail standard (more useful and popular), RAL RG620--Germany Guardrail standard, BS EN-1317-- European Guardrail standard, AS/NZS 3845:1999--Australian Guardrail standard, EN 1461:2009 - Turkish Guardrail Standard.

2. Q: Can I produce W beam and Thrie beam guardrails on one machine?

A: Yes, absolutely you can produce W beam and Thrie beam guardrails on one machine.

3. Q: How to change from producing W beam to thrie beam? And how long it takes?

A: According to the drawing given to replace forming rollers of last five forming station, process of changing just needs 30mins and only by one operator.

4. Q: What is delivery time of highway guardrail roll forming machine?

A: 80 days to 100 days depends on your drawing.

5. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally line speed is around 8m/min.

6. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

7. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

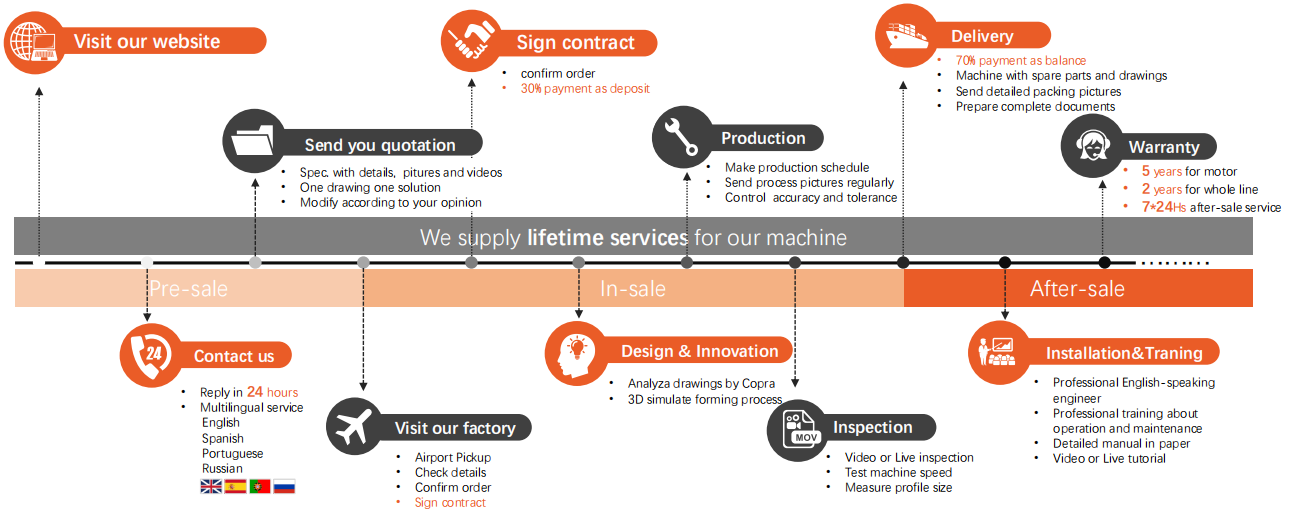

Purchase Service

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table