Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Hot New Products China Highway Guardrail Protect Panel Roll Forming Machine, We welcome prospects, small business associations and buddies from all pieces in the globe to get hold of us and search for cooperation for mutual positive aspects.

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of China Highway Guardrail Machine, crash barrier roll forming machine, Guardrail Forming Machine, guardrail machine, guardrail machine manufacturers, guardrail machine suppliers, Guardrail Roll Forming Machine, highway crash forming machine, Highway fence roll forming machine, Highway Guardrail Forming Machine, highway guardrail machine, Highway Guardrail Roll Forming Machine, Highway protection fence making machine, Highway safety fence machine, W-Beam machine, W-Beam roll forming machine, With many years good service and development, we’ve a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Description

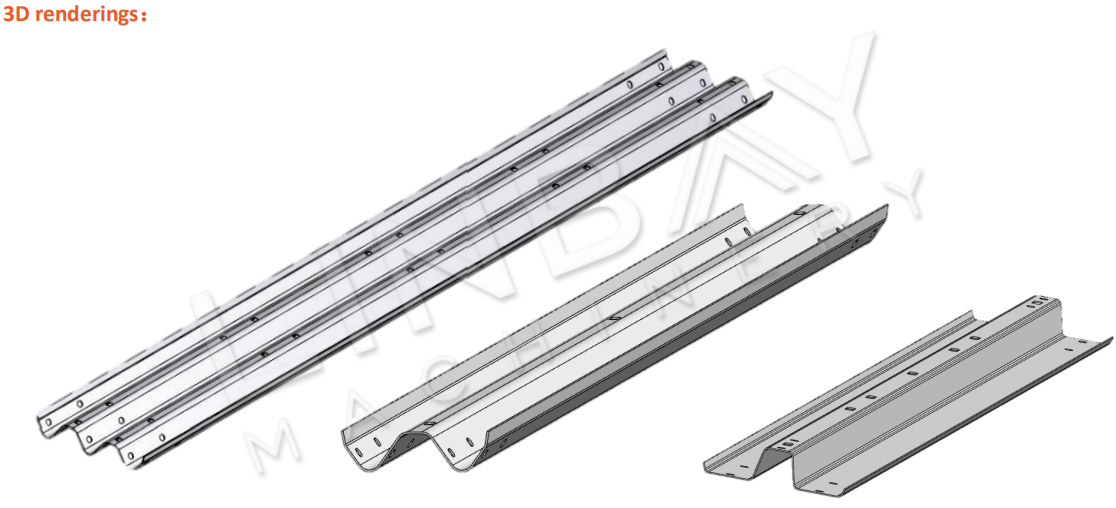

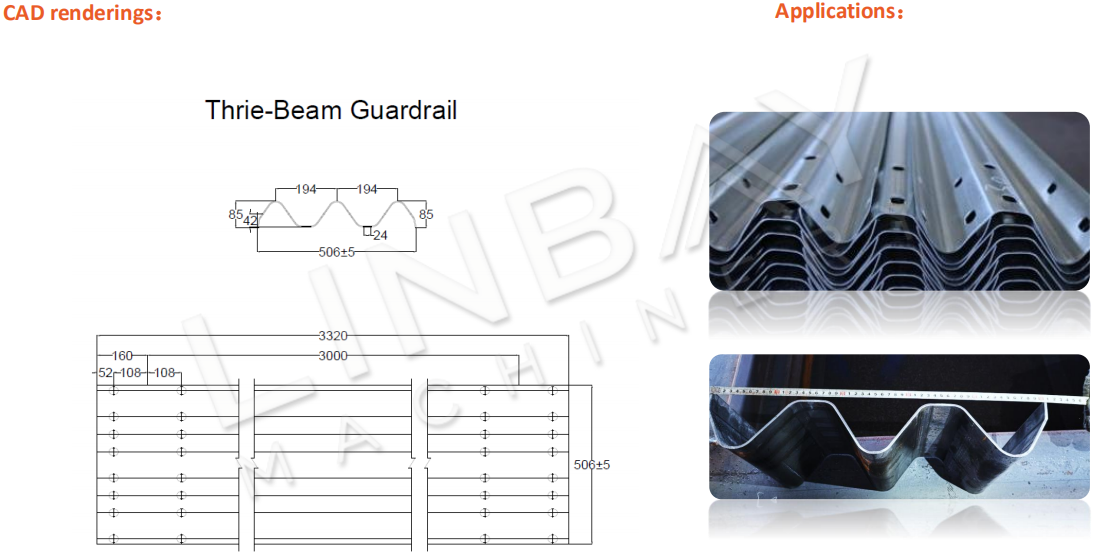

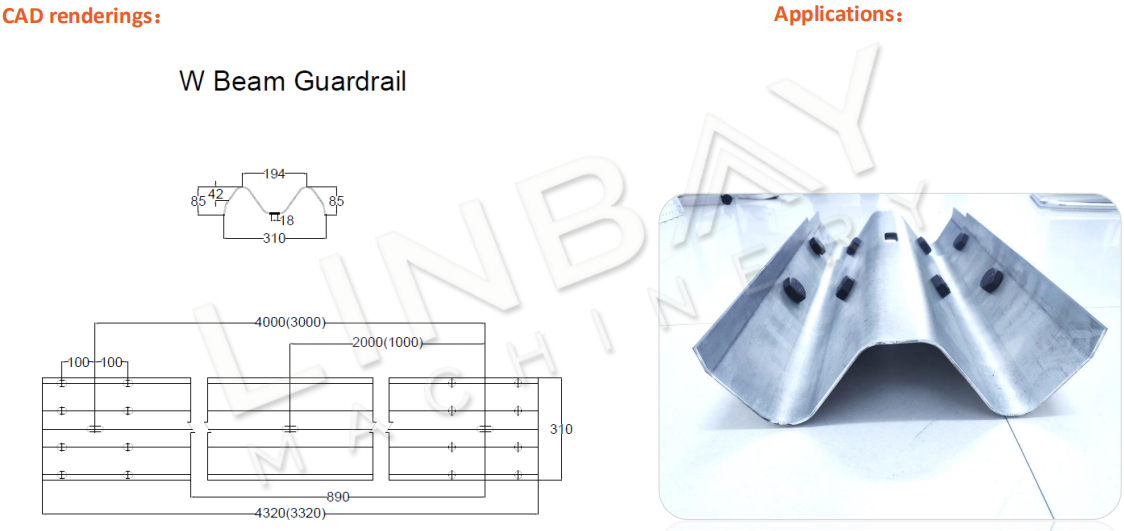

Highway Guardrail Roll Forming Machine can make W beam guardrail, flex-beam guardrail, thrie-beam guardrail and Box Beam Guardrail, also can be designed as two waves or three waves profiles in one machine, you just need to add some forming stations at the end of the machine according to our drawing. The guardrail’s thickness is usually 2.7mm-4mm.

Also Linbay have experience of producing guardrail roll forming machines whose products can meet different standards :

• AASHTO M180–American Guardrail standard (more useful and popular)

• RAL RG620–Germany Guardrail standard

• BS EN-1317– European Guardrail standard

• AS/NZS 3845:1999–Australian Guardrail standard

• EN 1461:2009 – Turkish Guardrail Standard

In guardrail machine industry there are four lines totally we could offer with quality:

• Two/three wave guardrail roll forming machine

• U/C/sigma post roll forming machine

• Connection punching line

• Fishtail end terminal punching line

Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Application

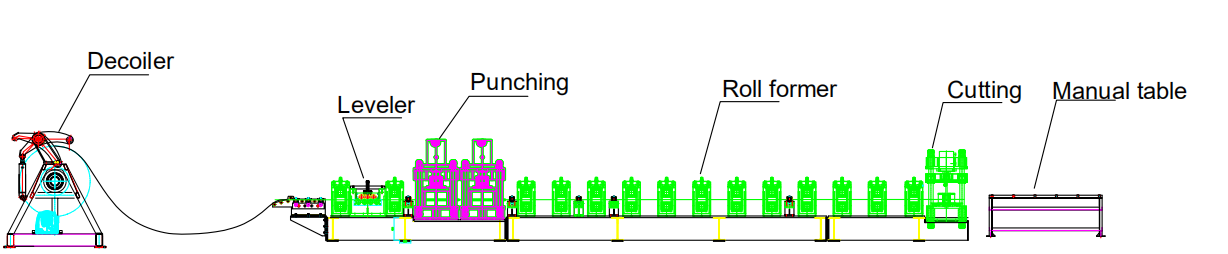

Real Case A

Description:

This guardrail roll forming machine is set up near our factory to produce Chinese government guardrail project. This line speed can reach 8m/min and we use transport platform to protect floor. This line can produce W beam guardrail and thrie beam guardrail. It’s efficient, durable and economic.

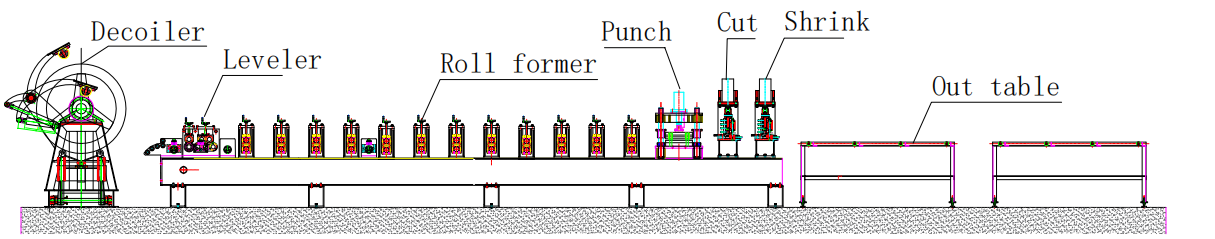

Real Case B

Description:

This guardrail roll forming machine uses a post cut flow chart, which is more affordable and popular with customers. We have exported this line to Russia and Saudi Arabia. All process are included, offering lower price but ensuring a perfect quality.

Real Case C

Description:

This guardrail roll forming machine is more asked and purchased by Turkish customers. The profile is particular developed by DELTA BLOC and meet standard EN 1461:2009. It has a shrink mould at the end of production line.

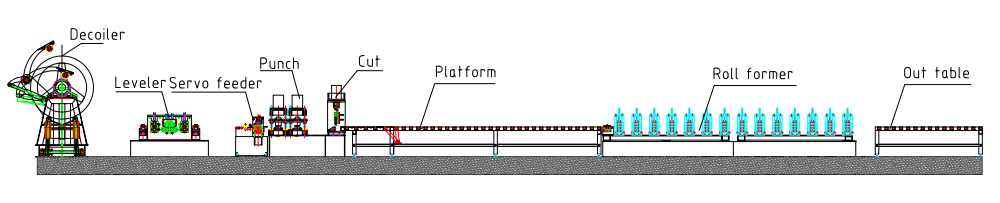

Whole production line of Highway guardrail roll forming machine

Technical Specifications

| Highway Guardrail Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 2.7-4 |

| B) Mill(Plain/Black) Steel | ||

| C) Carbon steel | ||

| Yield strength : | 250 – 350 Mpa | |

| Tensil stress : | 300 Mpa-500 Mpa | |

| Decoiler : | Hydraulic decoiler | * Manual decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | 12-15 stands | * According to your profile drawings |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Gearbox drive | * Chain drive (Optional) |

| Machine structure: | Forged Iron station | * Torri station (Optional) |

| Forming speed : | 10-15 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

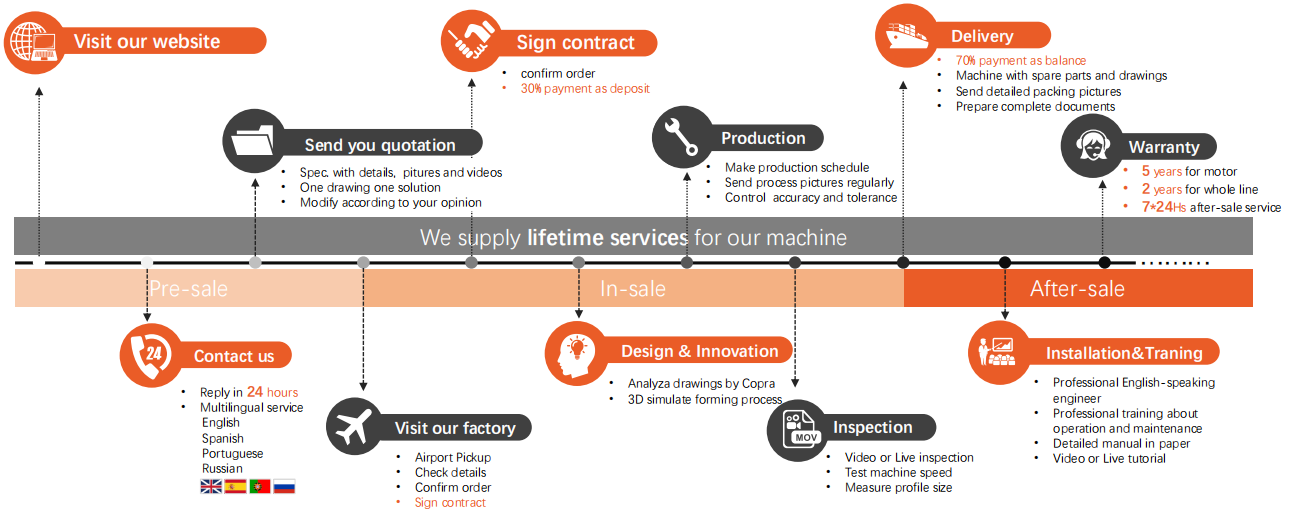

Purchase Service

Q&A

1. Q: What kinds of experience do you have in producing highway guardrail roll forming machine?

A: We have experience of exporting our highway guardrail roll formers to Russia, Saudi Arabia, Turkey, Indonesia, India etc. We have produced AASHTO M180–American Guardrail standard (more useful and popular), RAL RG620–Germany Guardrail standard, BS EN-1317– European Guardrail standard, AS/NZS 3845:1999–Australian Guardrail standard, EN 1461:2009 – Turkish Guardrail Standard.

2. Q: Can I produce W beam and Thrie beam guardrails on one machine?

A: One operator adds or takes off 5 stations of rollers according to our drawing. It wouldn’t more than 30 minutes..

3. Q: How to change from producing W beam to thrie beam? And how long it takes?

A: According to the drawing given to replace forming rollers of last five forming station, process of changing just needs 30mins and only by one operator.

4. Q: What is delivery time of highway guardrail roll forming machine?

A: 80 days to 100 days depends on your drawing.

5. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally line speed is around 8m/min.

6. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

7. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Online Exporter Latest CZ Purlin Steel Profiled...

-

Bottom price China High Output Shelf Pallet Rac...

-

China Supplier China Manual/Hydraulic Shelf Box...

-

Top Suppliers China Energy Efficiency Supermark...

-

2019 wholesale price China Manufacturer Steel S...

-

Professional China High Speed Fully Automatic H...