Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Hot-selling China Aluminium Scaffolding Plank for Building Walk Board Roll Forming Machine with High Quality, We sincerely welcome domestic and foreign retailers who calls, letters inquiring, or to crops to barter, we’ll supply you high-quality merchandise as well as the most enthusiastic company,We look forward in your go to and your cooperation.

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for China Scaffolding Machine, construction platform making machine, scaffold board rolling machine, scaffold foot pedal machine, Scaffold plank roll forming machine, scaffolding foot plate machine, Scaffolding Platform roll former, scaffolding walk plank machine, Walk Board Machine, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Description

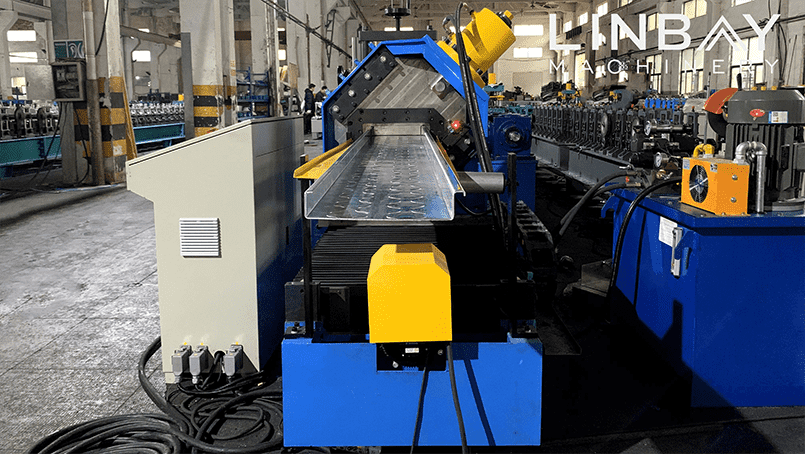

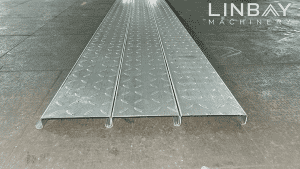

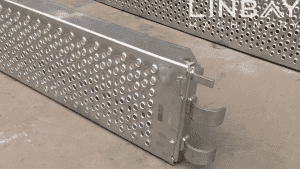

Scaffold plank roll forming machine can make scaffold plank. We adopt servo feeder to make sure the holes are in high precision. We use punching press to make line speed faster and we use hydraulic post cutting to make sure the profile perfect.

The thickness of raw material is around 1-2mm.

Application

Technical Specifications

Flaw Chart

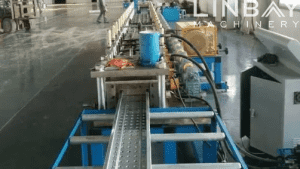

Manual decoiler–feeding–hydraulic punching station–forming machine–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

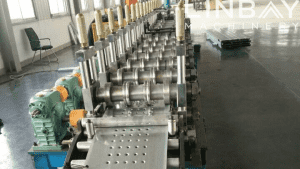

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table