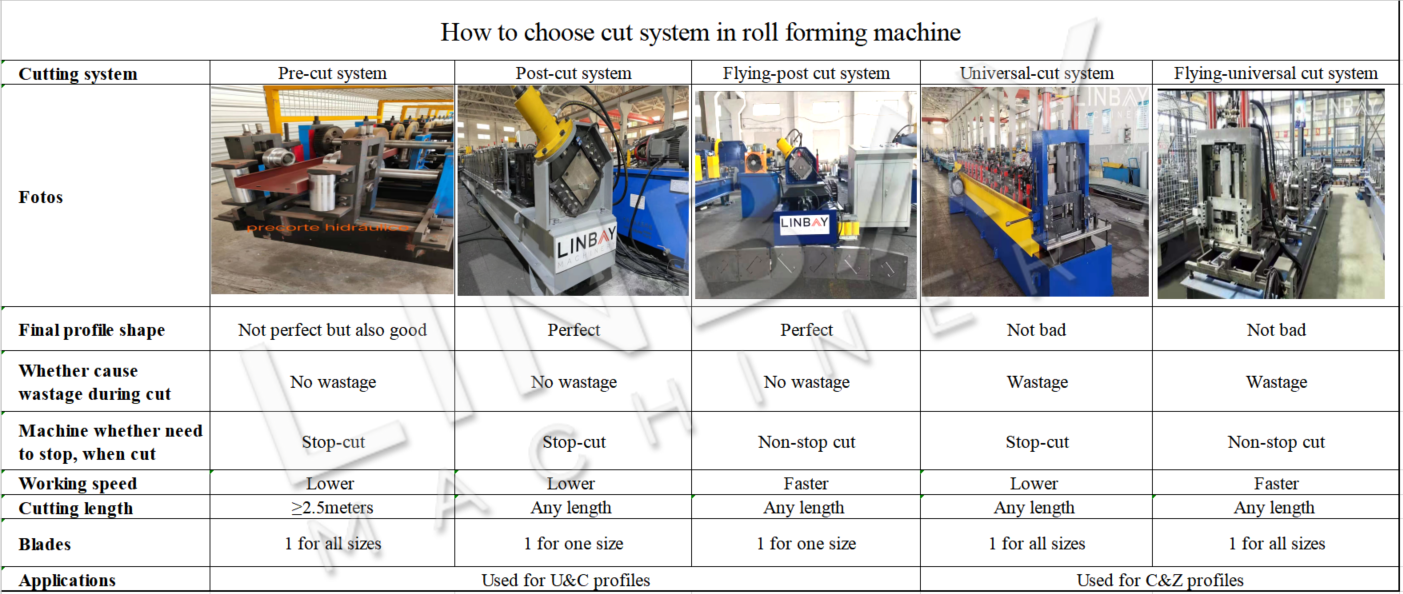

In the new year, Linbay Machinery will continue to share more professional and technical details about roll forming machine. Today, we will introduce the differences between pre-cut system, post cut system and universal cut system and how to choose in roll forming machine.

1.Pre-cut system

It is a cutting system that cut sheet before roll forming part, so there is no need to consider blades change if there are multiple sizes to produce. Pre-cut system is more economical indeed, and can help you save time and cost from changing blades of different sizes. Meanwhile it won’t produce any material waste when cut the sheet. But it only applies to the long sheets over 2.5 meters, and the shape of sheet profiles cut by pre-cut system is not good-looking compared with post-cut system.But it’s also good and acceptable.

Tips from Linbay Machinery: If you don’t have very strict demand on profile shape, and also don’t pursue higher production efficiency, pre-cut system will be your most economical choice based on the condition that the length of the sheet must exceed 2.5m.

2.Post-cut system

It is a cutting system that cut length after roll forming part. If the size that you need to produce is not too much, and also you have a higher demand for the shape of profiles. It is most cutting system that we recommend. We will customize each blade according to the size that you provide us, before cut there is also a rectify device to make sure the profile perfect, so it will be more beautiful.We can also provide you bevel-post cut system, there is no any material waste during the cutting process, to a certain extent, this is also a way to help you save more materials and costs. In addition ,there is a excellent advantages for post cut system, it has no limit to the cutting length, you can cut sheets at any length according to your need. Finally,if you want to improve your production efficiency, we can improve our technology correspondingly, and provide you flying-post cut system. Flying-post cut system is an advanced cutting way compared with ordinary post-cut system, there is no need to stop the roll forming motor when you cut the length, we can provide you machine to meet your demand for production efficiency.

Tips from Linbay Machinery: If your budget is abundant, the profile size is not multiple, and also pursue perfect sheet shape, post-bevel-cut system can fulfill all your demand.

3.Universal-cut system

It is a cutting system that cut sheet after roll forming part too, and it applies to multiple sizes and C profile with Z profile. If you have many sizes that need to produce, universal-cut system will be your best choice, because it doesn’t need to change blades for all sizes, neither for C profiles neither for Z profiles. It is widely used at C&Z purlin quick changeable machine. It can help you save lots of blade-change costs. But there is material waste during the cutting process. And it can’t confirm wonderful profile shape. Same as post-cut system, we can provide you flying-universal cut system if you have big production needs.

Tips from Linbay Machinery:

If there are multiple sizes, universal-cut system will be your optimal solution, especially for C&Z purlin profiles.

Hope all professional recommendations that we provide can give you a deep understanding about roll forming machine, and make best choice for cutting system according to your situation.

If you have any question about roll forming machine, please feel free to talk with Linbay Machinery, we are trusty and reliable in quality and post-sales service. Linbay Machinery will not let you down.

Post time: Feb-20-2021