Our steel metal roll forming machines are of good quality. But now in the market our price is a little bit higher than other suppliers. Let me explain about our machines:

The basic line of the machine is

Manual uncoiler--Feeding--Roll former--Cutting--Out table.

And I will explain from the details.

The 5 Ton Manual decoiler, just like this picture, it is made of square tubes, and has brakes.

(5 ton Decoiler)

But we recommend you to use the hydraulic decoiler, because normally, the steel coil for metal sheet is big and heavy, if the manual decoiler is not in the right position, i.e. on the centre line of the roll forming machine, it will damage the metal sheet in the feeding.

The hydraulic decoiler supports the coil with hydraulic power and rotating motor, it is more convenient and does not damage the raw material.

(5-10 ton hydraulic decoiler)

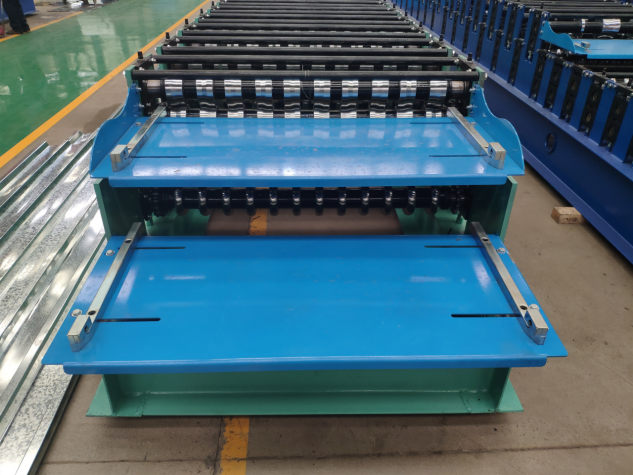

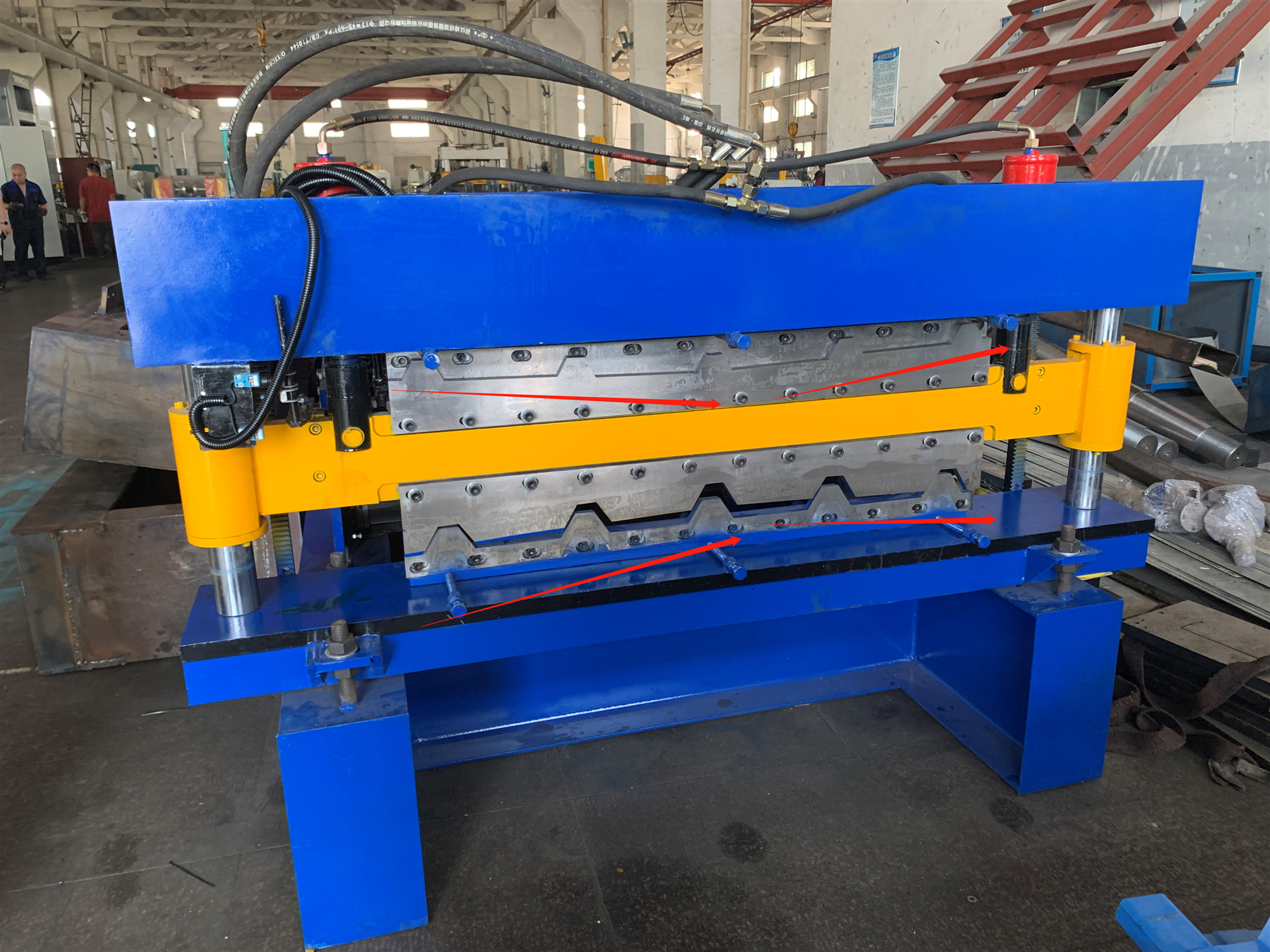

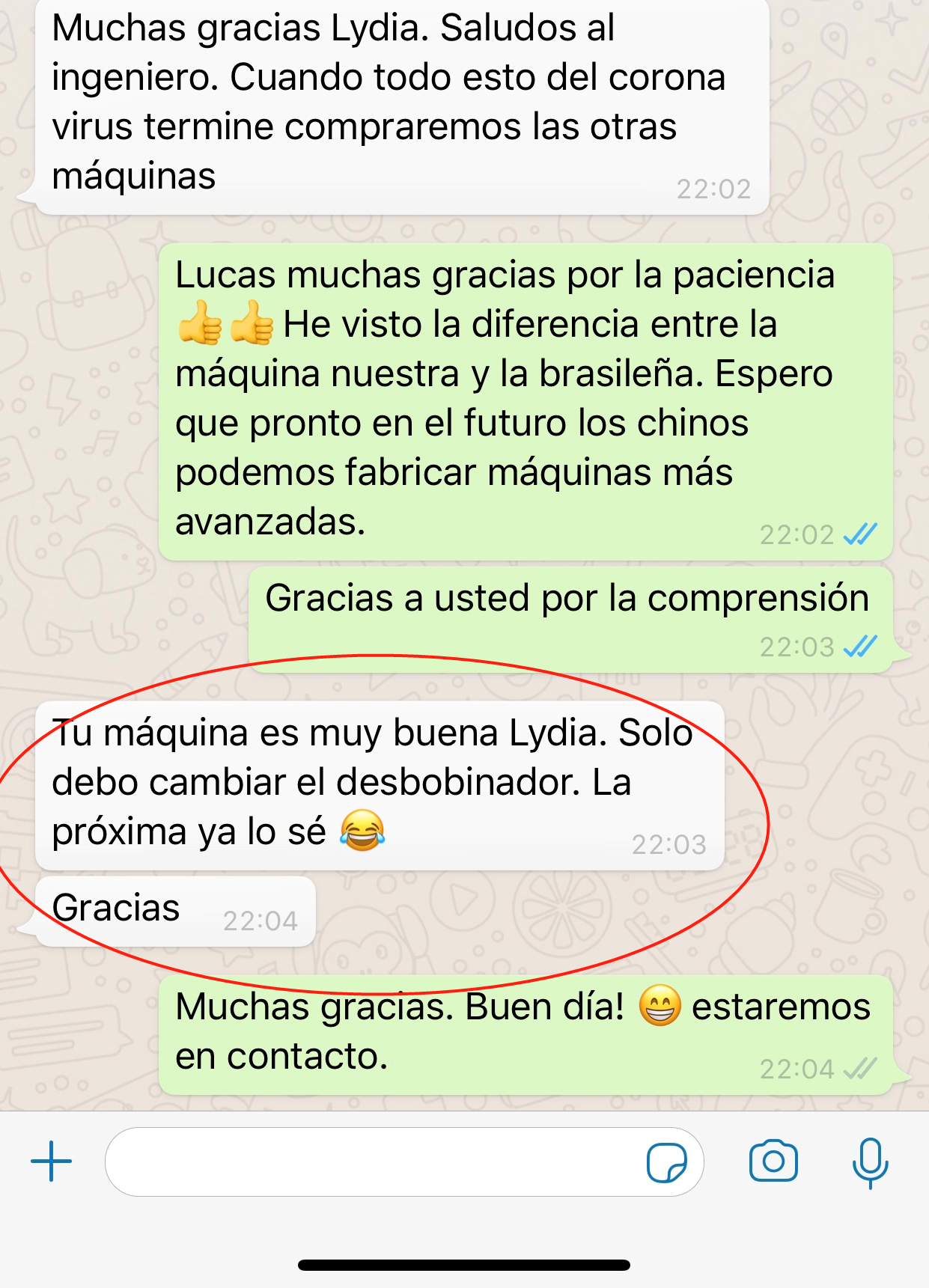

The roll forming machine with electric or hydraulic cutting. Our machine is more robust and easier to use. It produces the most beautiful profiles. The metal sheet produced by our machine is always flat, because in the design and during the machining process, we always control the force for the metal sheet, it does not damage the surface and comes out perfect profile.

1. We have 2 design engineers, they are very experienced in their work.

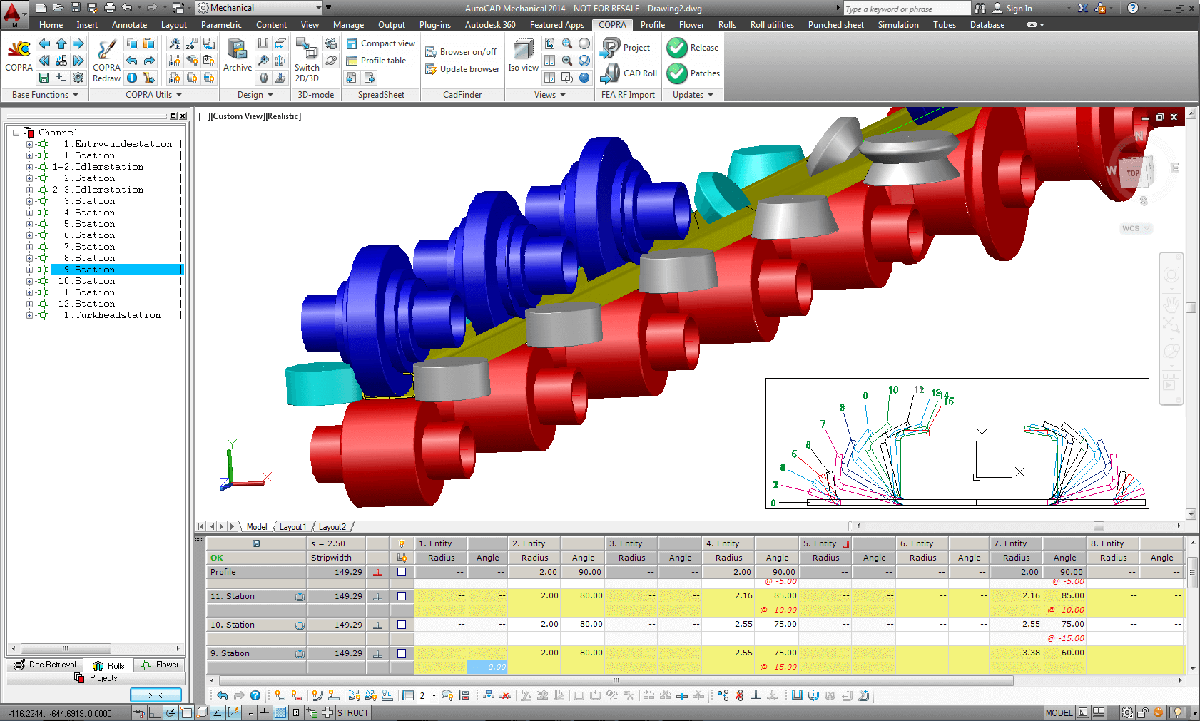

2. We use the German application COPRA, to imitate the situation in 3D and ensure the perfect profile. Normally we have more forming steps so that the sheet comes out flat and meets the standards. And also our machine can produce the profile with thickness from 0.3mm to 0.8mm.

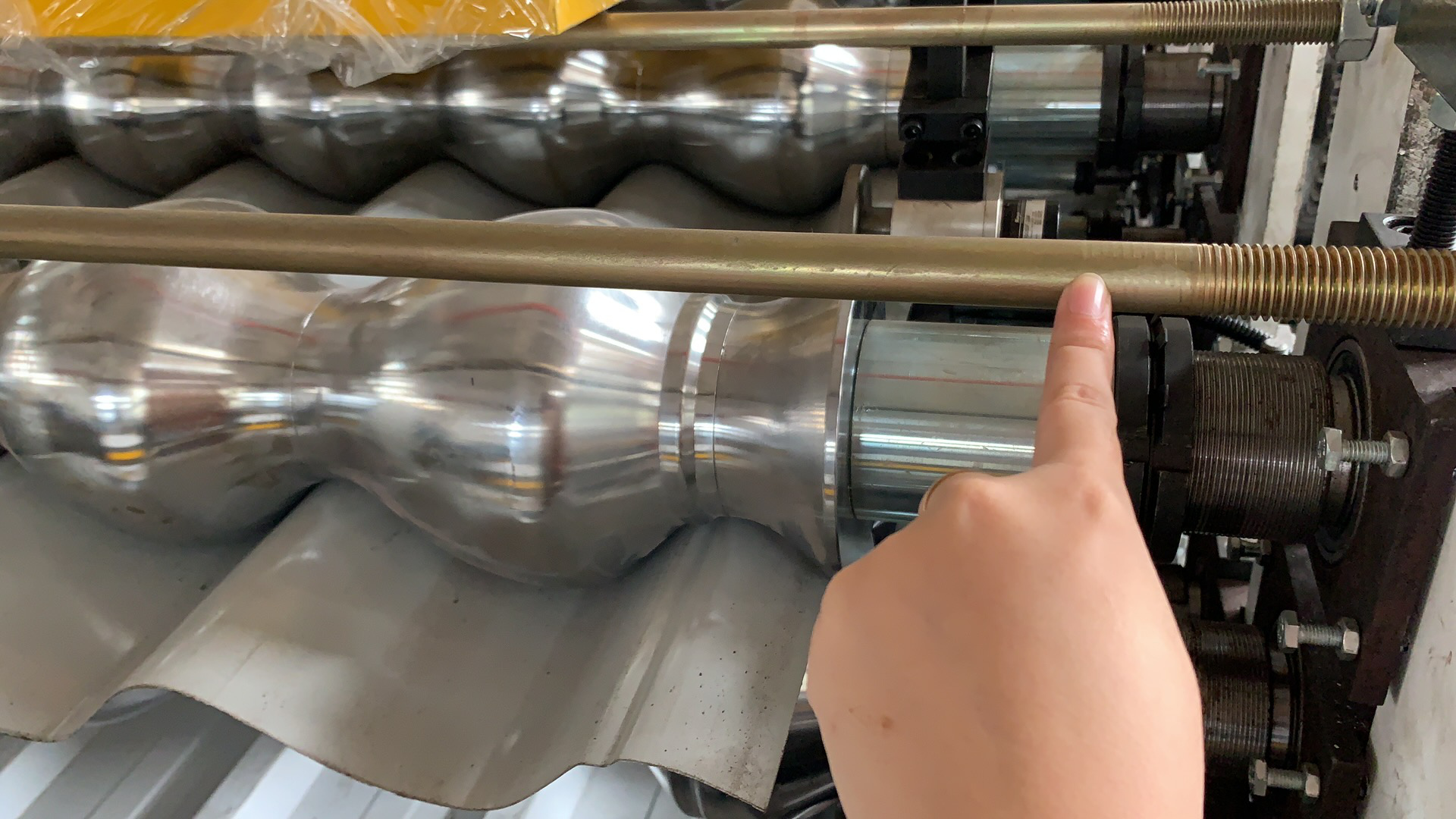

3. All the rollers are machined by many steps, and in the end we cover them with 0.5mm chrome. All rollers are shiny and avoid rust.

4. The shaft we use in the machine is 75mm, it is fixed, each shaft weighs 75kgs.

5. The seals we use is 75mm diameter, it is larger than other supplieres

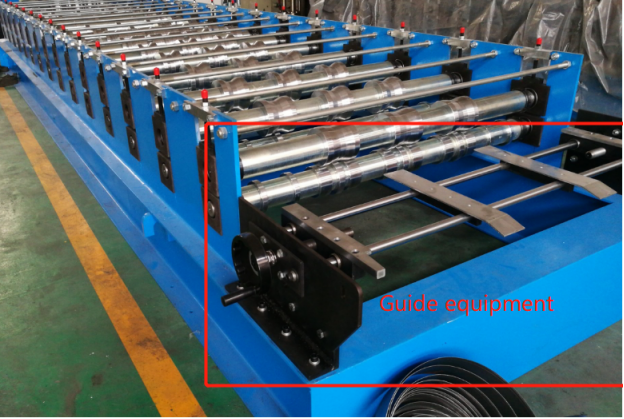

6. When the steel width is different, turn the crank to fix the steel.

(Linbay Machinery)

(other suppliers)

7. The screw rod we use in the machine is made of alloy steel. And it is totally solid.

(Screw rods from Linbay Machinery)

(Screw rods from other suppliers)

8. The nuts, washers and bolts that we use on the machine are well chrome plated, it will not be rusted over time.

9. The cutting: The blade of our cutting can cut 2 million. For trapezoidal or corrugated sheet, we have started to use the electric cut, which has 4 columns (two columns more than the hydraulic cut), it is stronger and faster. When cutting the sheet, there is no any burr on the profile.

(Cutting from Linbay Machinery)

(Cutting from other suppliers)

10. Our machine for making trapezoidal or corrugated roof weighs 6010kgs, and with all the components, the line weighs 7500kgs, but normally the machine's weigh for other supplieres only 4-5 tons. And our machine has more forming steps.

11. And we also offer the chain cover, to protect the operators.

12. Let's see, how look the roof tiles?

(Linbay Machinery)

(Otros suppliers)

That is to say, although it is the same profile, the shaped sheets come out different, Linbay Machinery's tile is more beautifully and flat with high standard, the other suppliers' tile is twisted. This is because their design does not take into account the raw material, the forming process, the strength in the plate, etc. And this is not shown in the quotation.

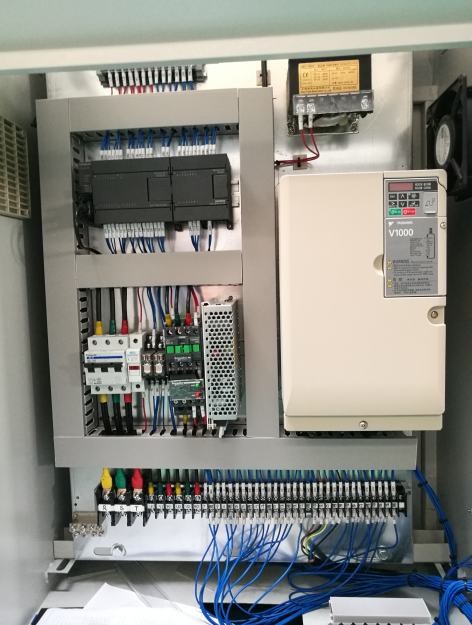

We use Yaskawa frequency inverter for the uncoiler control. The other low-voltage elements are CHNT brand, which is the best brand in China. And it has the sensor to detect the metal sheet

(Electric box from Linbay Machinery)

(Electric box from other suppliers)

In the control system for the roll forming machine, we use all the components of famous brand:

Encoder: Koyo

PLC: SIEMENS OR PANASONIC

Electrical elements: Schneider

Frequency inverter: Yaskawa

(Linbay Machinery)

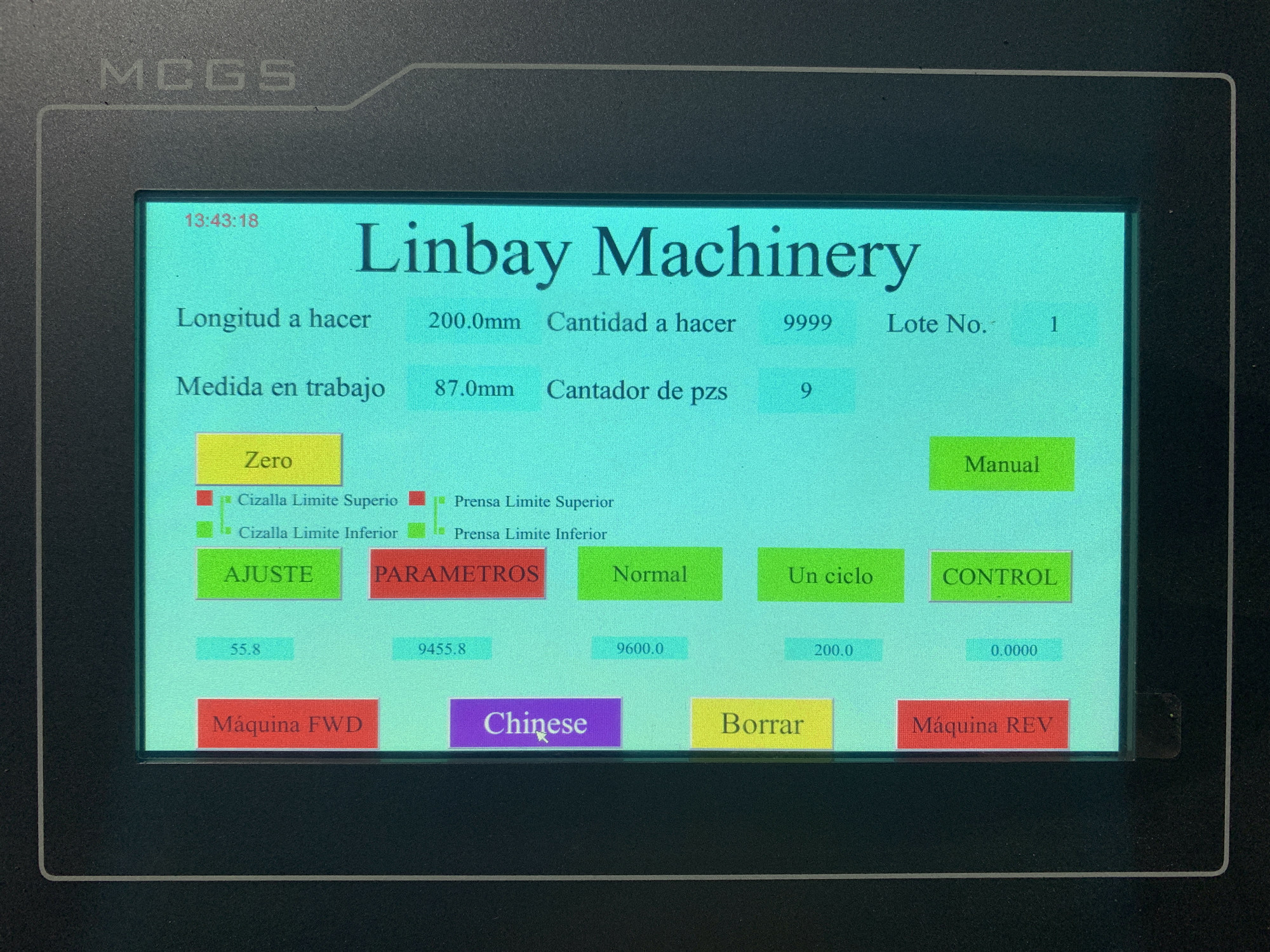

On the touch screen, it can be Spanish.

And we also offer instruction manual in English(or Spanish) to show you how to use the machine.

And we have installation video in English, also Spanish to show you how to assemble the machine.

We provide two out tables, each table is 2 metres long.

We provide instruction in Spanish, installation video in Spanish.

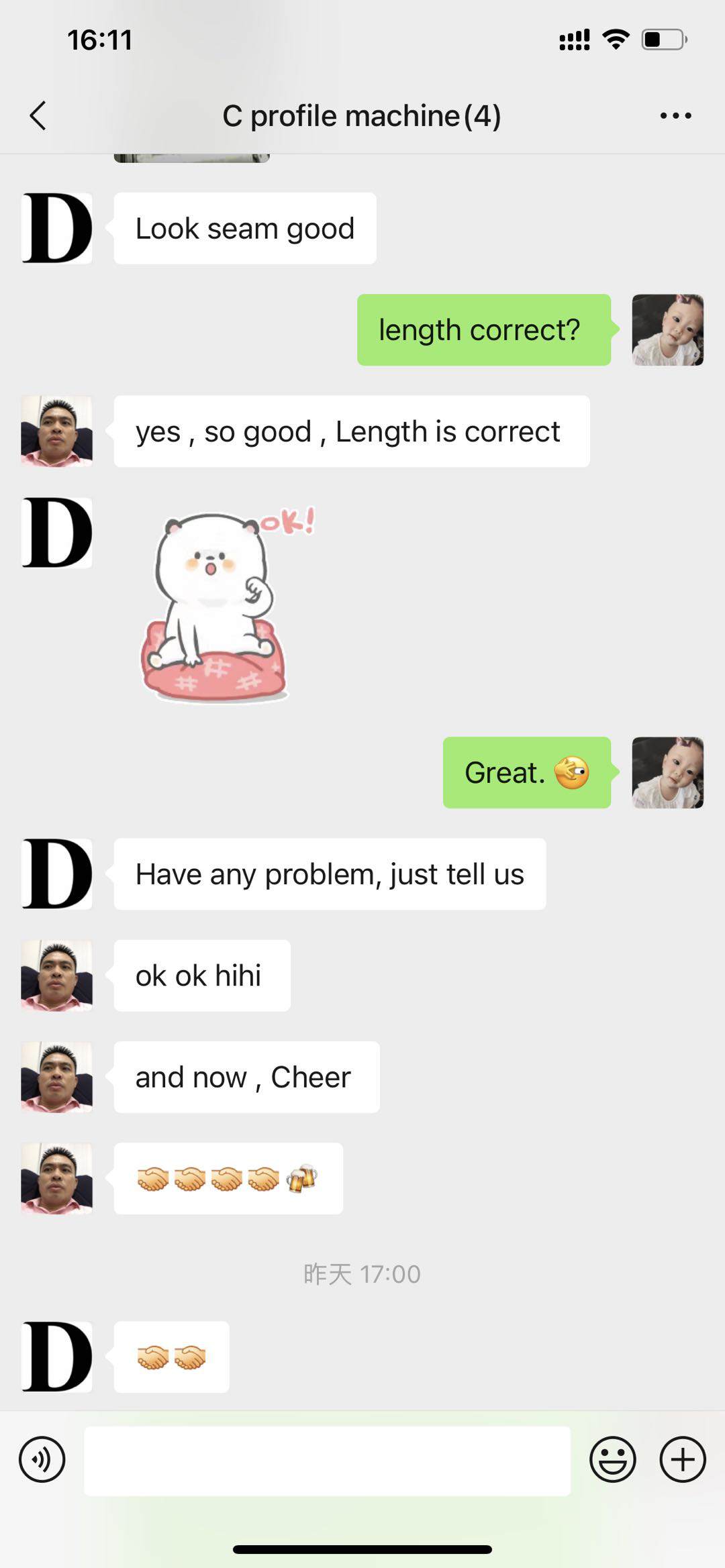

When you receive the machine, it will be well adjusted in profile and length, you can start production right away.

In the end, why is our price higher?

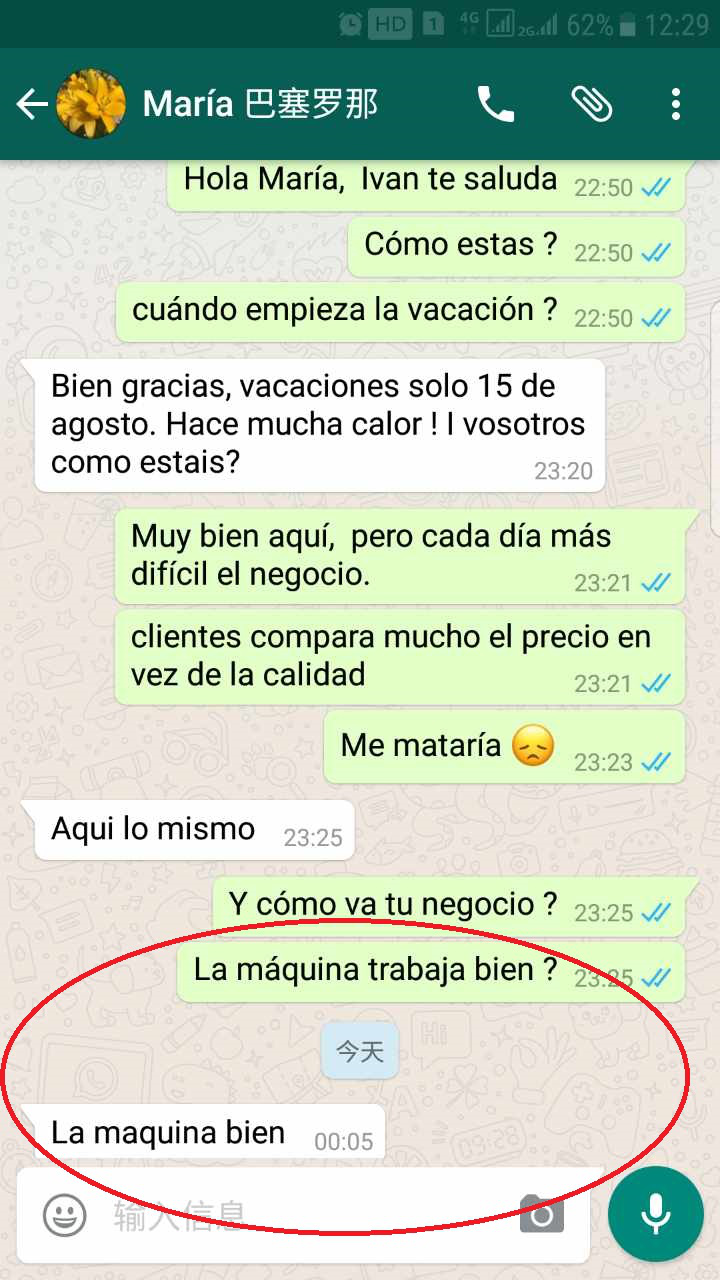

Because we offer all good and qualitified components, our machine uses PLC with Panasonic or Siemens brand, frequency inverter with Yaskawa brand, encoder for length with Koyo brand. We have professional engineers. We use Copra application. In addition to English, we also offer better services for Spanish-speaking customers. We have the touch screen in Spanish, the manual in Spanish and the video in Spanish. If you buy machines from Linbay Machinery, we always offer you the best quality with the service, we assure you that when you receive the machine, you can start the production right away. It is easy to install and use.

If you are interested, please contact Linbay Machinery.

Post time: Feb-25-2021