kanema

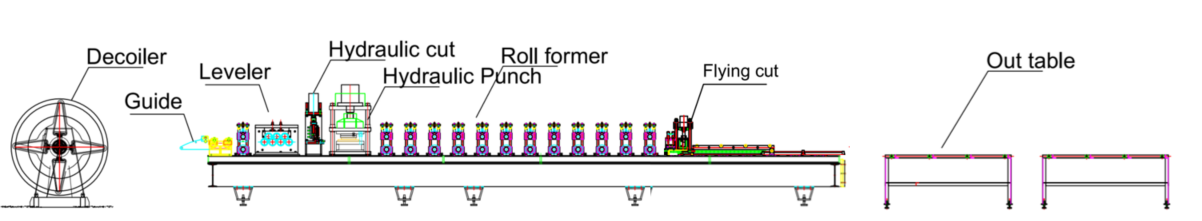

Mbiri

Mzerewu umatha kupanga makulidwe osiyanasiyana amtundu wa C, mtundu wa Z, ndi ma purlin amtundu wa M okhala ndi digiri yayikulu yodzichitira. Ndi kusankha kotsika mtengo kwa ndalama.

Tchati choyenda

Decoiler

Timayika akukanikiza-mkonopa decoiler kuti agwire koyilo yachitsulo pamalo ake posintha ma koyilo, kuteteza kumasulidwa mwadzidzidzi komanso kuvulaza antchito. Komanso,zitsulo zoteteza masambazimayikidwa kuti ziteteze kutsetsereka kwa koyilo panthawi yotsegula. Kapangidwe kameneka kamangoteteza koyilo yachitsulo ndi makina komansozimatsimikizira chitetezo.

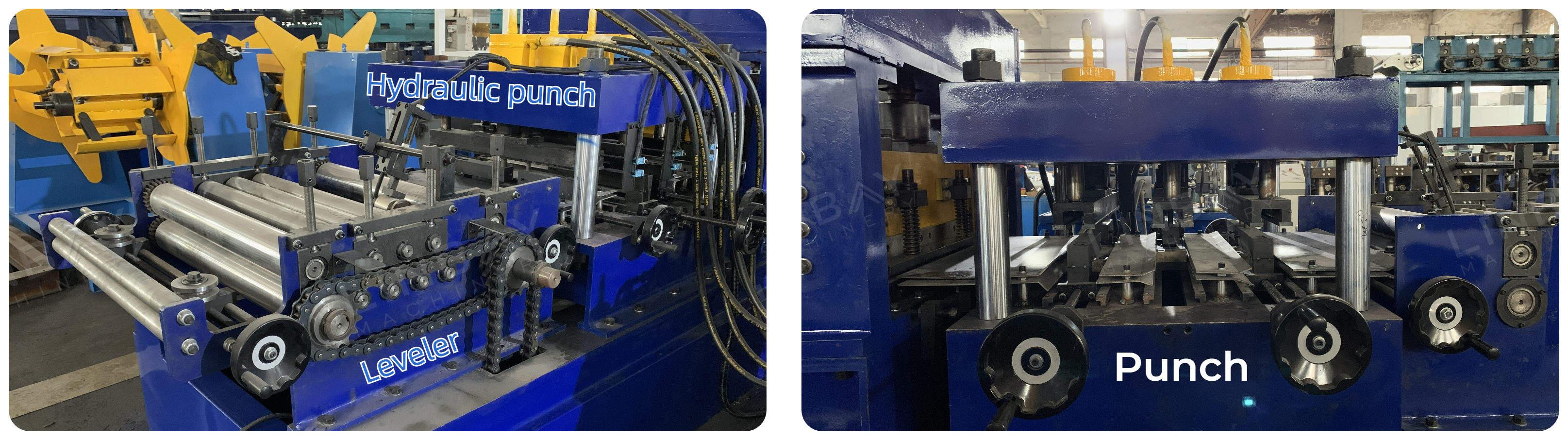

Wotsogolera & Leveler

Zodzigudubuza zowongolera zimasunga koyilo yachitsulo ndi makina omwe ali pakati pa mzerekupewa kupotozaza ma profiles opangidwa. Ma roller angapo owongolera amayikidwa motsatira njira yonse yopanga. Ndiyeno, koyilo yachitsulo imalowa mu leveler, yomweamachotsa zolakwika zilizonse, kukulitsa kusalala ndi kufananawa coil chuma. Izi nazonso,amawongolera khalidwezonse za coil ndi chomaliza cha purlin.

Mphamvu ya Hydraulic

Makina a hydraulic punching amabwera ndimagawo atatu a ufandi masilinda amafuta ofananira. Izi zitha kukhalamwachangu komanso mosavutakusinthidwa kuti akwaniritse zofunikira za kasitomala, kuperekakusinthasintha kwambiri. Njira yosinthira kufa ndiyothandiza ndipo nthawi zambiri imamalizidwa mkati5 mphindi.

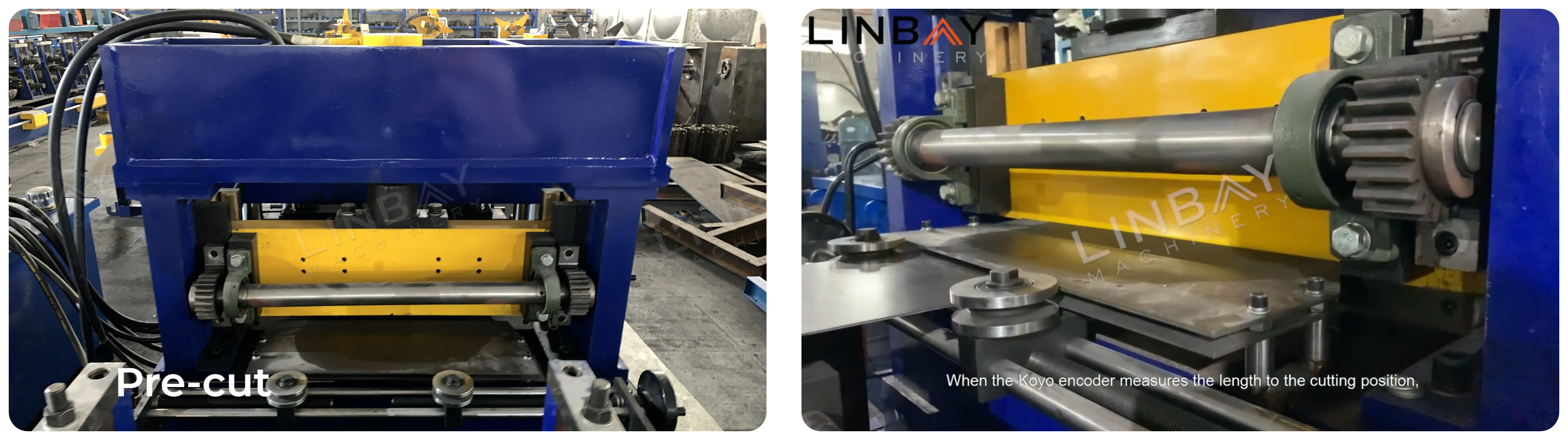

Pre kudula

Kuwongolera kusinthika kosavuta kwa makulidwe osiyanasiyana a coil kuti apange makulidwe osiyanasiyana ndikusunga zopangira, chipangizo chodulira chisanadze chimapangidwa kuti chizigwira ntchito bwino,kuchepetsa zinyalala.

Leveler, kukhomerera makina ndi makina odulira amaphatikizidwa ndi makina opangira mpukutu, omwe ndiabwino kwambirimapangidwe okwera mtengo.

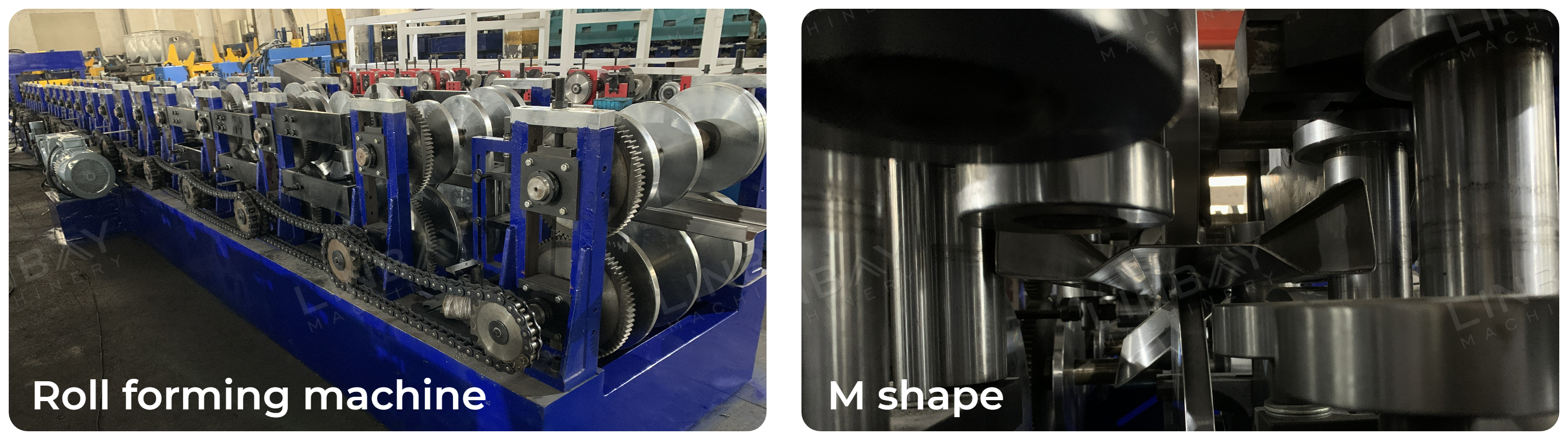

Pereka kale

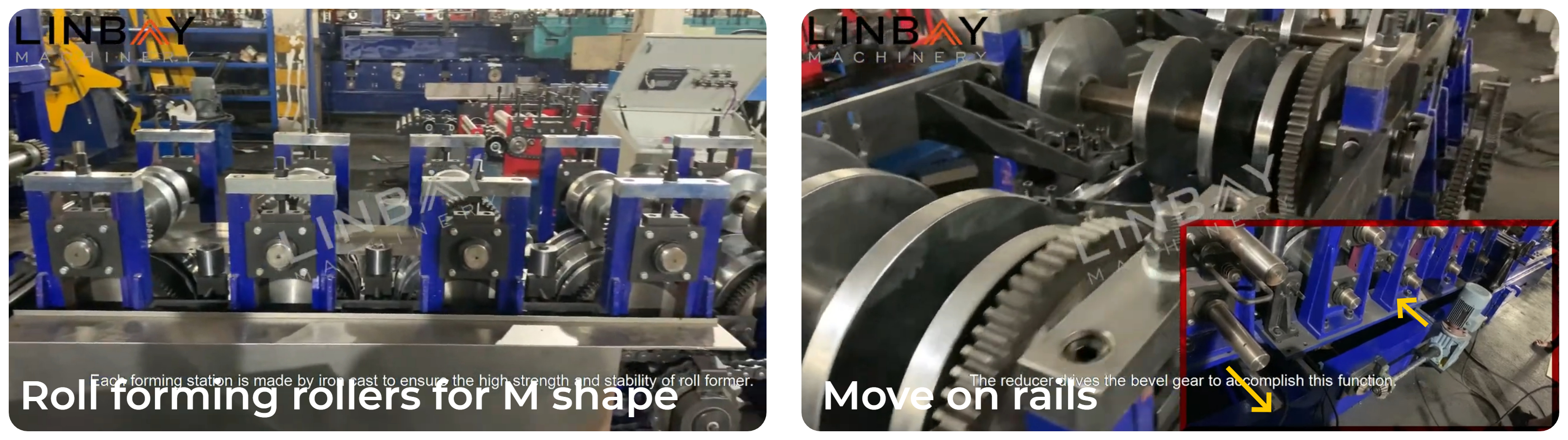

Makina opangira mpukutuwo amakhala ndi akapangidwe kachitsulo-chitsulondichain drive system. Mapangidwe achitsulo-chitsulo ndichitsulo cholimba, kuonetsetsa kulimba ndi kukhazikika. Makinawa amatha kupangaC, Z, ndi Sigma purlins. Zodzigudubuza zinayi zoyambirira zimagwiritsidwa ntchito pa mawonekedwe a Sigma, ndipo amakwezedwa akamapanga mawonekedwe a C kapena Z. Komanso, pozungulira pamanja2-3 kupanga masiteshoni ndi 180 °, mutha kusinthana pakati pa kupanga C ndi Z purlins. Malo opangira mbali imodzi ya makina amasunthira panjanji kuti apange purlinsm'lifupi mwake. Ndikofunikira kudziwa kuti, tikapempha, titha kupanganso makina a purlin omwe amasiyanasiyanakutalika ndi pansi m'lifupinthawi imodzi.

Ma hydraulic station

Malo athu opangira ma hydraulic ali ndi fani yozizirira yomwe imathandizira kuti pakhale kutentha koyenera, kuonetsetsakuchuluka kwachangupa ntchito mosalekeza.

Encoder&PLC

Ogwira ntchito amatha kuwongolera makinawo kudzera pa zenera la PLC, kusintha ma speed, kukhazikitsa miyeso kupanga, ndi kudula utali, etc. Encoder imaphatikizidwa pamzere wopanga, kutembenuza kutalika kwa koyilo yachitsulo kukhala ma siginecha amagetsi omwe amatumizidwa ku gulu lowongolera la PLC. Izi zimapangitsa makina athu kuti asamalirekudula mwatsatanetsatane mkati mwa 1mm, kutsimikizira zinthu zapamwamba komansokuchepetsa kuwononga zinthuchifukwa cha zolakwika zodula.

Timapereka ntchito zosinthira makonda, kuphatikiza koma osalekeza kumitundu yamagalimoto, mtundu, mtundu wamagetsi, ndi chilankhulo cha PLC control panel.

1. Decoiler

2. Kudyetsa

3.Kukhomerera

4. Mipukutu yopangira zoyimira

5. Kuyendetsa galimoto

6. Kudula dongosolo

Ena

Kunja tebulo