kanema

Mbiri

Cross bracing imakhala ndi gawo lofunikira pamakina oyikamo, kulimbikitsa kuthandizira ndi kukhazikika pakati pa mafelemu awiri owongoka. Wopangidwa kuchokera kuchitsulo chakuda chokhazikika chokhala ndi makulidwe oyambira 1.5 mpaka 2.5mm, utoto wopangidwa pambuyo pake umathandizira kukulitsa dzimbiri ndi dzimbiri, kuonetsetsa kuti moyo wautali komanso wodalirika.

Mlandu weniweni-Main Technical Parameters

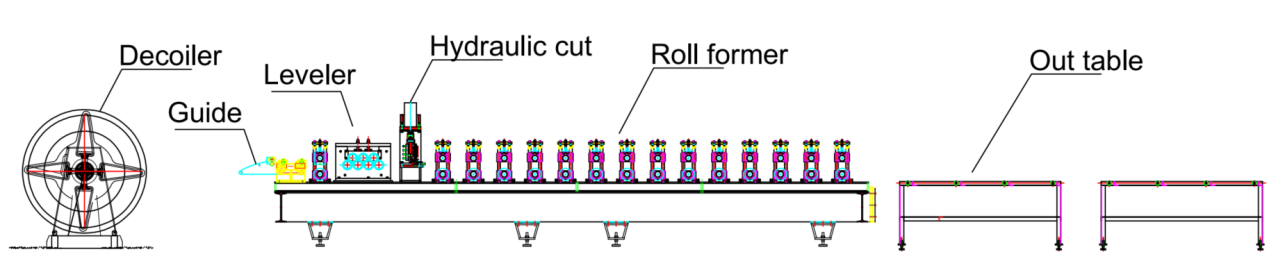

Tchati choyenda: Decoiler--Kutsogolera--Leveler--Predula--Pereka mawonekedwemakina opangira--Kunja tebulo

- 1.Liwiro la mzere: 0-15m / min, chosinthika

- 2.Dimensions muzochitika zenizeni: Angapo m'lifupi 80-300mm, kutalika kwa 50mm

- 3.Zinthu zoyenera: Zitsulo zamagalasi

- 4.Kukula kwazinthu: 1.5-2mm

- 5.Roll kupanga makina: Cast-iron dongosolo ndi unyolo kuyendetsa galimoto

- 6.Kudula dongosolo: Dulani musanapange makina opangira mpukutu, ndi mphamvu ya hydraulic.

- 7.PLC nduna: Siemens dongosolo.

Mlandu weniweni-Makina

1.Decoiler*1

2.Leveler(Wokonzeka pa makina opangira mpukutu)*1

3.Makina a Hydraulic pre-cut *1

4.Makina opangira gudumu*1

5.Kunja tebulo*2

6.PLC control cabinet*1

7.Hydraulic station*2

8.Bokosi lazigawo (Zaulere)*1

Nkhani yeniyeni-Kufotokozera

- Decoiler

Nthawi zambiri, decoiler imakhala gawo loyamba la mzere wopanga. Dzanja lake losindikizira limatha kuteteza koyilo yachitsulo, kuteteza kuvulala kuti zisawonongeke panthawi yakusintha kwa coil. Zipangizo zakunja zosungira ma coil zimalepheretsanso ma coil kuti asasunthe kuchokera pa mandrel.

Kutsogolera

Ma roller owongolera amawongolera bwino koyilo yachitsulo muzodzigudubuza kuti asunge kulumikizana pakati pa koyilo yachitsulo ndi makina opangira mpukutu, kuchepetsa kupindika kapena kupatuka kulikonse.

Leveler

Makulidwe a mtandawo amafika 2.5mm, ndipo pokhapokha atawongoka bwino komanso osapotoka amatha kupereka kukhazikika kwabwino kwa chimango choyikapo. Makina osanjikiza amatha kuwongolera koyilo yachitsulo, kutulutsa kupanikizika kwamkati, kupangitsa kuti ikhale yosavuta kupanga ndi kupanga molunjika. Mu mzere wopangawu, makina owongolera amayikidwa pamakina opangira makina, omwe amatha kupulumutsa malo pansi ndikuchepetsa mtengo wamtunda.

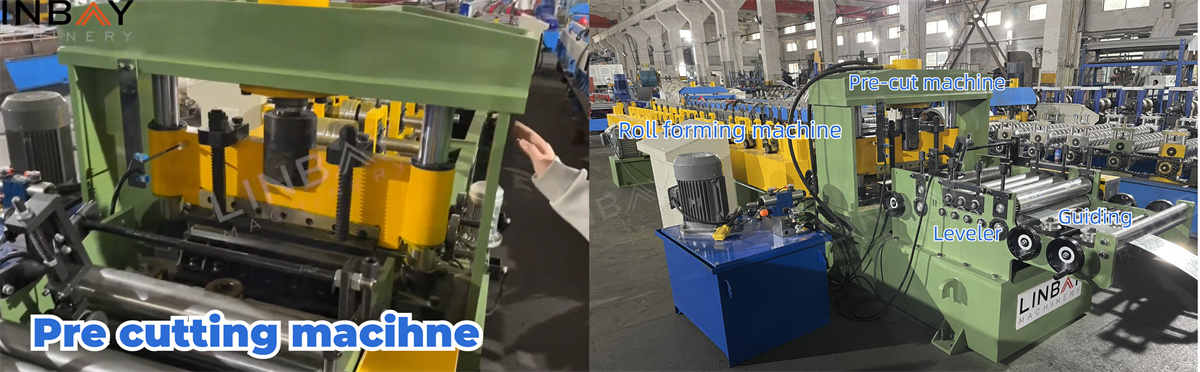

Makina oduliratu

Poyerekeza ndi kudula pambuyo, kudula chisanadze musanapange sikungowononga. Njira yothetsera vutoli imathandizira kusintha kosavuta kwa ma koyilo achitsulo amitundu yosiyanasiyana kuti apange makulidwe angapo pamzere womwewo wopangira, popanda kuwononga chilichonse.

Pereka mawonekedwemakina opangira

Makina opangira mpukutu ndiye gawo lofunikira kwambiri pamzere wonse wopanga. Imagwiritsa ntchito chitsulo cholimba chopangira chitsulo chopangirapo, chopangidwa kuchokera kuchitsulo cholimba. Kuzungulira kwa odzigudubuza kumayendetsedwa ndi dongosolo la unyolo.

Zopangira zodzigudubuza ndi Gcr15, chitsulo chokhala ndi carbon chromium chokhala ndi chitsulo chodziwika bwino chifukwa cha kulimba kwake komanso kukana kuvala. Zodzigudubuza zili ndi chrome-zokutidwa kuti ziwonjezere moyo wawo wautumiki. Ma shafts amapangidwa ndi zinthu za 40Cr ndipo amathandizidwa kutentha.

Zowonjezera zimaphatikizidwa pansi pa mbiriyo kuti ziwonjezere mphamvu zake. Makina opangira mpukutuwa amatha kupanga kukumbatirana ndi m'lifupi mwake 80-300mm ndi kutalika kwa 50mm. Polowetsa miyeso yomwe mukufuna mu gulu lowongolera la PLC, malo opangira amasuntha njanji kupita pamalo oyenera komanso olondola. Malo opangirawo amasinthanso pamene malo opangira akuyenda.

Pachitetezo chakuyenda kwa ma station, 2 masensa mtunda amaikidwa pa maziko a makina, lolingana ndi malo akunja ndi amkati omwe akupangasiteshonisikhoza kusunthidwa ku.Kwa masensa, tmalo ake ozindikira ndiPanokumaziko a malo opangira. Zamkatimusensandi kutetezakupangasiteshoniskuyandikira kwambiri ndikuyambitsa kugunda kwa ma roller.Chakutsogolosensandi kutetezakupangasiteshoni kuti asachoke panjanjindi kugwa.

Ma hydraulic station

Malo opangira ma hydraulic amabwera ndi mafani oziziritsa omwe amapangidwira kuti azitha kutentha bwino, kutsimikizira kugwira ntchito mosadodometsedwa komanso kukulitsa zokolola. Wodziwika chifukwa cha kulephera kwake kochepa, malo opangira ma hydraulic awa amamangidwa kuti azikhala, kuwonetsetsa kukhazikika kwanthawi yayitali.

PLC control cabinet & Encoder

Encoder imatembenuza kutalika kwa koyilo yachitsulo kukhala ma siginecha amagetsi omwe amatumizidwa ku kabati yowongolera ya PLC. Mkati nduna ulamuliro, liwiro kupanga, munthu linanena bungwe kupanga, kudula kutalika, ndi magawo ena akhoza kusamalidwa. Ndi miyeso yolondola komanso mayankho kuchokera ku encoder, makina odulira amatha kuwongolera zolakwika mkati mwa ± 1mm.

1. Decoiler

2. Kudyetsa

3.Kukhomerera

4. Mipukutu yopangira zoyimira

5. Kuyendetsa galimoto

6. Kudula dongosolo

Ena

Kunja tebulo