kanema

Mbiri

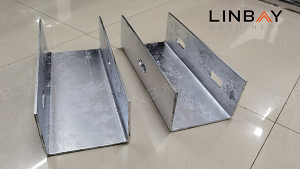

Cross bracing ndiyofunikira pamakina olemetsa, omwe amapereka chithandizo cha diagonal pakati pa mikwingwirima iwiri. Imathandiza kupewa kugwedezeka ndikusunga makonzedwe apangidwe pansi pa katundu wolemetsa. Nthawi zambiri, kuwombana kumapangidwa kuchokera kuzitsulo zotentha, zozizira, kapena malata okhala ndi makulidwe a 1.5 mpaka 2 mm.

Mwachizoloŵezi, kupanikizana kumapangidwa pogwiritsa ntchito makina opindika. Komabe, mzere wa makina opangira mpukutuwo, womwe umaphatikizapo kumasula, kusanja, kupanga mipukutu, kukhomerera, ndi kudula, umapereka makina okwera kwambiri komanso kuchepetsa ndalama zogwirira ntchito. Yankho limeneli lakhala chisankho chokondedwa kwa makasitomala ambiri chifukwa cha mphamvu zake komanso zotsika mtengo.

Mitundu yokhomerera imasiyanasiyana kutengera njira yoyika:

Njira Yoyikirapo 1: Chingwe chimodzi chimayikidwa mkati mwachiyikapo chowongoka, chomwe chimafuna mabowo okhomeredwa kale pamtunda wa bracing kuti akhazikitse screw.

Njira Yoyikira 2: Zingwe ziwiri zimayikidwa mkati mwachiyikamo mowongoka, zomwe zimafuna mabowo okhomeredwa kale pansi pa chiwongolero chokhazikitsa screw.

Mlandu weniweni-Main Techinical Parameters

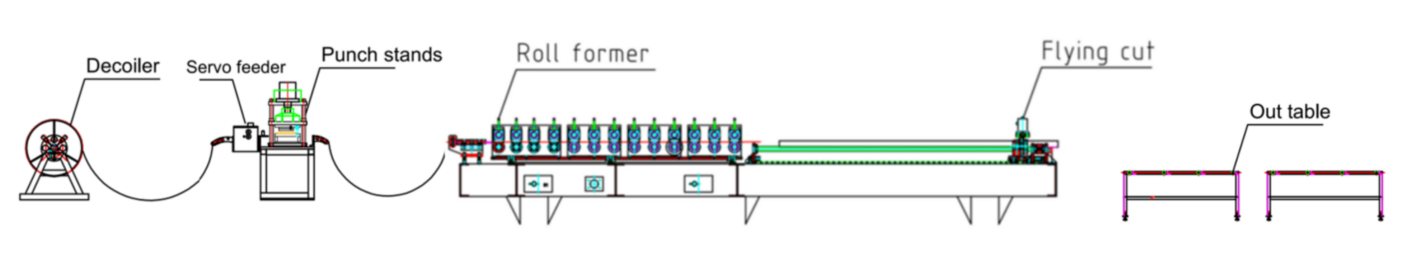

Tchati choyenda: Decoiler--Servo feeder--Hydraulic punch--Guiding--Roll forming machine--Flying hydraulic cutting--Out table

Poyerekeza ndi mizere iwiri yopanga mizere imodzi, mzere wopangira mizere iwiri ukhoza kukupulumutsirani mtengo wa makina owonjezera opangira, decoiler, ndi servo feeder, komanso malo ofunikira pamzere wina wopanga. Kuphatikiza apo, mawonekedwe amizere iwiri amachepetsa mtengo wanthawi yosinthira makulidwe, mosiyana ndi kusintha kwamanja pamzere umodzi, potero kumapangitsa kuti ntchito zitheke.

Mlandu weniweni-Main Technical Parameters

1.Liwiro la mzere: 4-6m / min, chosinthika

2.Zoyenera: Chitsulo chotentha chotentha, chitsulo chozizira, chitsulo chagalasi

3.Kukula kwazinthu: 1.5-2mm.

4.Roll kupanga makina: Kutaya-chitsulo kapangidwe

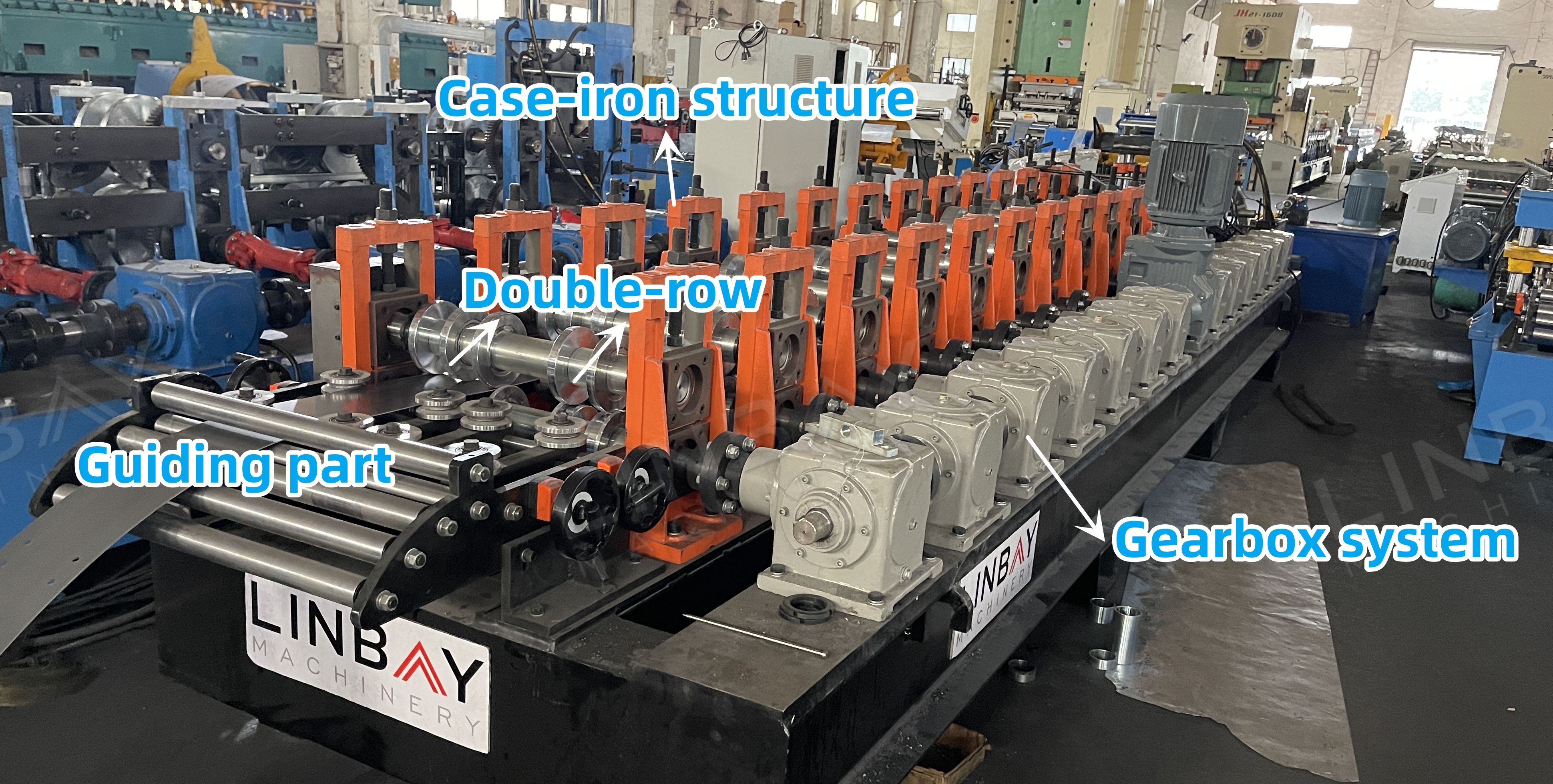

5.Driving system: Gearbox drive system

6.Kudula dongosolo: Kudula kwa hydraulic hydraulic, mpukutu wakale suima pamene kudula.

7.PLC nduna: Siemens dongosolo.

Mlandu weniweni-Makina

1.Hydraulic decoiler*1

2.Servo feeder*1

3.Makina a Hydraulic punch*1

4.Makina opangira gudumu*1

5.Makina odulira a Hydraulic*1

6.Kunja tebulo*2

7.PLC control cabinet*1

8.Hydraulic station*2

9.Bokosi lazigawo (Zaulere)*1

Nkhani yeniyeni-Kufotokozera

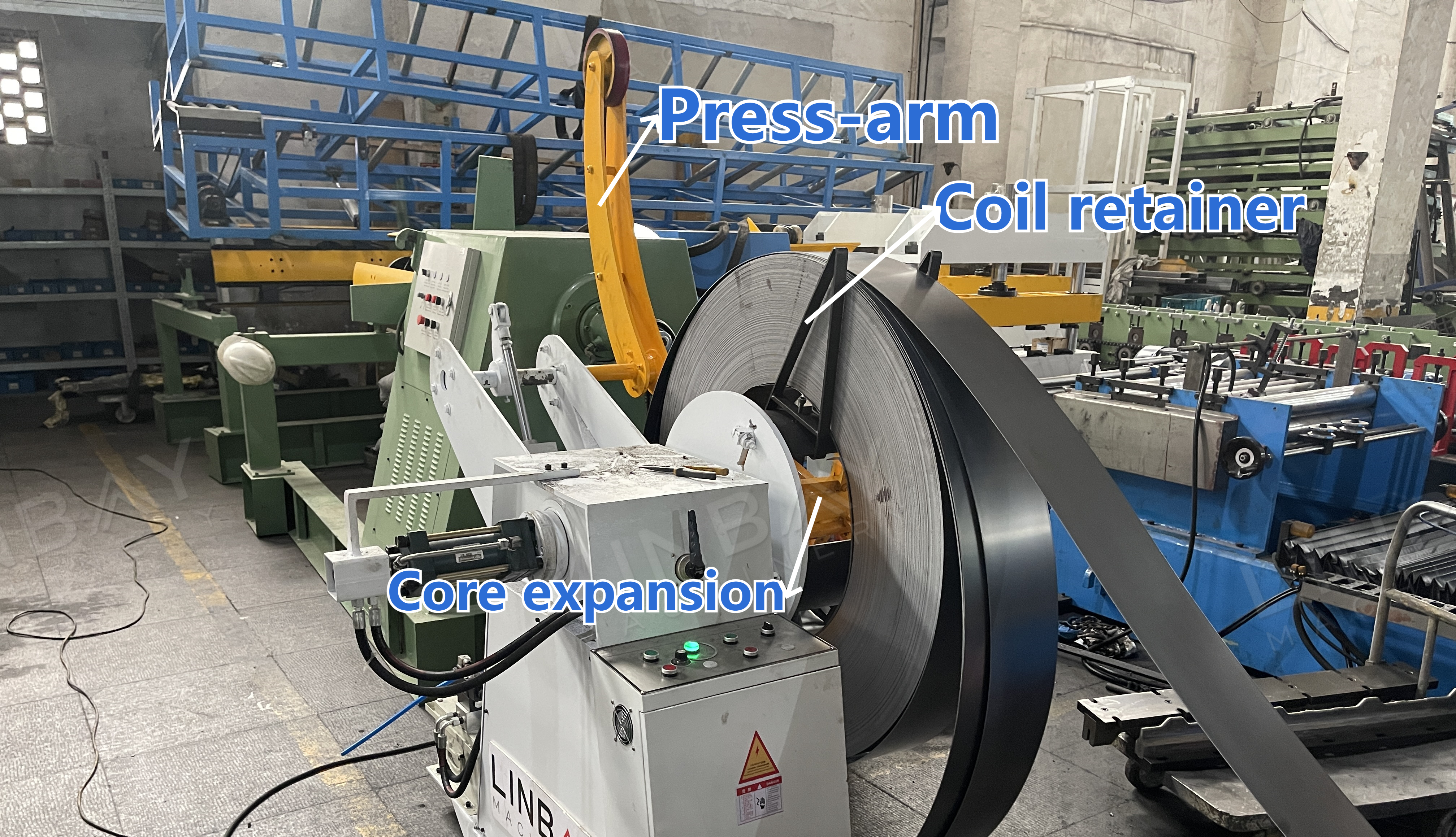

Decoiler

Shaft yapakati ya decoiler imathandizira koyilo yachitsulo ndipo imakhala ngati chipangizo chokulirapo, chokhala ndi ma coil okhala ndi mainchesi amkati a 490-510mm. Chipangizo chamkono chosindikizira chomwe chili pa decoiler chimateteza koyilo panthawi yotsitsa, ndikuletsa kuti isatseguke chifukwa chazovuta zamkati ndikuwonetsetsa chitetezo cha ogwira ntchito.

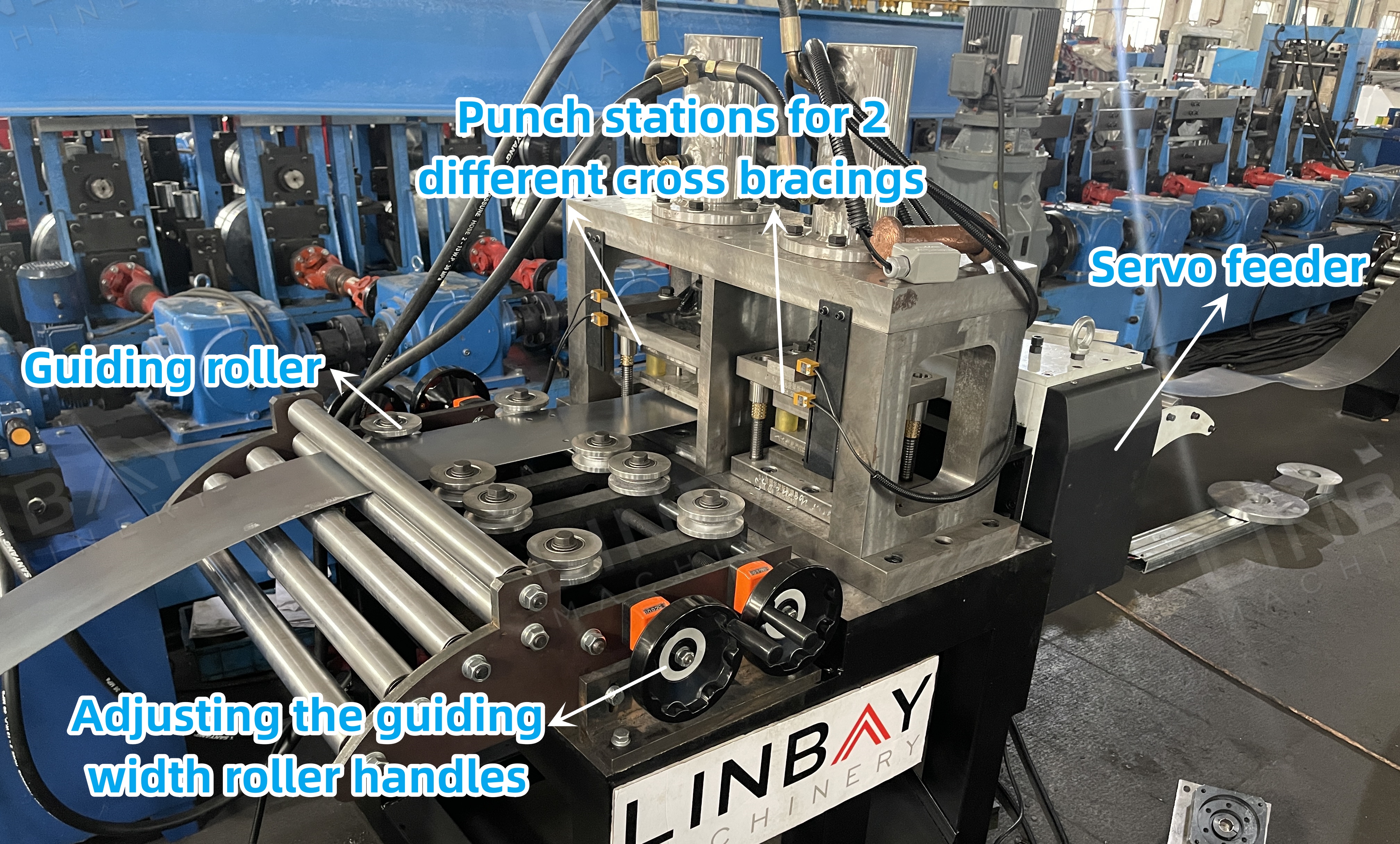

Hydraulic Punch & Servo Feeder

Punch ya hydraulic, yoyendetsedwa ndi hydraulic station, imapanga mabowo mu koyilo yachitsulo. Cross bracing imakhomeredwa mbali zonse ziwiri, mwina pa flange kapena pansi, kutengera zofunikira za kukhazikitsa. Pali makina oyimilira komanso ophatikizika a hydraulic punch. Mtundu wophatikizika umagawana maziko omwewo ndi makina opangira mipukutu ndikuyimitsa makina ena panthawi yokhomerera.

Chingwe chopangachi chimagwiritsa ntchito mtundu woyimirira, kupangitsa kuti makina opangira decoiler azigwira ntchito mosalekeza panthawi yokhomerera, kuwonetsetsa kuti palibe kusokonezedwa. Mtundu wa standalone umaphatikizapo servo feeder yoyendetsedwa ndi servo motor, yomwe imachepetsa kuchedwa koyambira ndikuwongolera bwino kutalika kwa koyilo kuti ikhomedwe molondola. Makina a mpweya wa mpweya mkati mwa feeder amateteza pamwamba pa coil kuti zisapse.

Kutsogolera

Ma roller owongolera amawonetsetsa kulumikizana koyenera kwa koyilo ndi makina kuti apewe kupotoza panthawi yopanga, popeza kuwongoka kwa mtanda kumakhudza mwachindunji kukhazikika kwa alumali.

Makina Opangira Roll

Makina opangira awa amadzitamandira ndi chitsulo chachitsulo komanso makina a gearbox. Ndikofunika kuzindikira kuti mizere yonse iwiri sigwira ntchito nthawi imodzi. Pakupanga kwapamwamba, timalimbikitsa mzere wopangira wosiyana pakukula kulikonse.

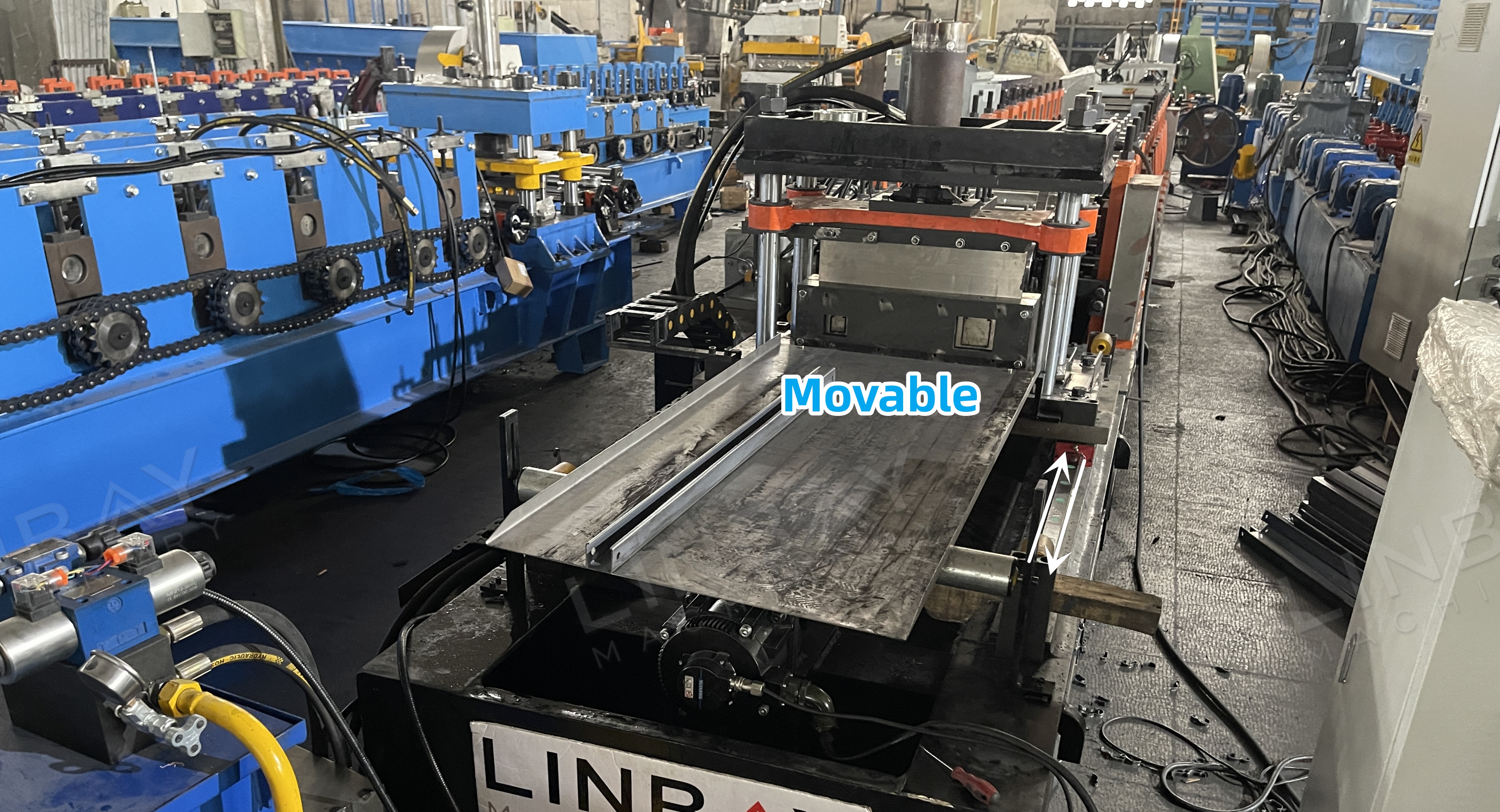

Flying Hydraulic Cutting

Mapangidwe a "zowuluka" amathandizira kuti makina odulira azitha kuyenda motsatira njanji, kulola kudyetsa koyilo mosalekeza kudzera pamakina opangira popanda kuyimitsa kudula, motero kumakulitsa liwiro la mzere wonse.

Tsamba lodulira liyenera kukhala logwirizana ndi mawonekedwe ake, zomwe zimafunikira tsamba losiyana pakukula kulikonse.

Chipangizo Chosankha: Shear Butt Welder

Kumeta ubweya wa ubweya kumagwirizanitsa ntchito zonse zometa ndi kuwotcherera, kulola kugwirizanitsa zitsulo zatsopano ndi zakale zachitsulo. Izi zimachepetsa kuwononga zinthu, zimachepetsa nthawi yosintha koyilo, komanso zimathandizira kusintha. Imagwiritsa ntchito kuwotcherera kwa TIG kuti iwonetsetse kuti pali zosalala komanso zosalala.

Sitima ya Hydraulic

Malo opangira ma hydraulic amakhala ndi mafani oziziritsa kuti athe kutenthetsa bwino, kuwonetsetsa kuti akugwira ntchito mosalekeza komanso kuchita bwino. Imazindikiridwa chifukwa chodalirika komanso kugwira ntchito kwanthawi yayitali.

PLC Control Cabinet & Encoder

Encoder imasintha kutalika kwa koyilo yoyezedwa kukhala ma siginecha amagetsi a kabati yowongolera ya PLC. Kabichi iyi imayendetsa liwiro la kupanga, zotulutsa pa kuzungulira, ndi kutalika kwa kudula. Chifukwa cha mayankho olondola kuchokera ku encoder, makina odulira amakwaniritsa kulondola kwa kudula mkati mwa ± 1mm.

1. Decoiler

2. Kudyetsa

3.Kukhomerera

4. Mipukutu yopangira zoyimira

5. Kuyendetsa galimoto

6. Kudula dongosolo

Ena

Kunja tebulo