Description

Octagonal tube is accesory of shutter slat door.

There are three types more used in market.

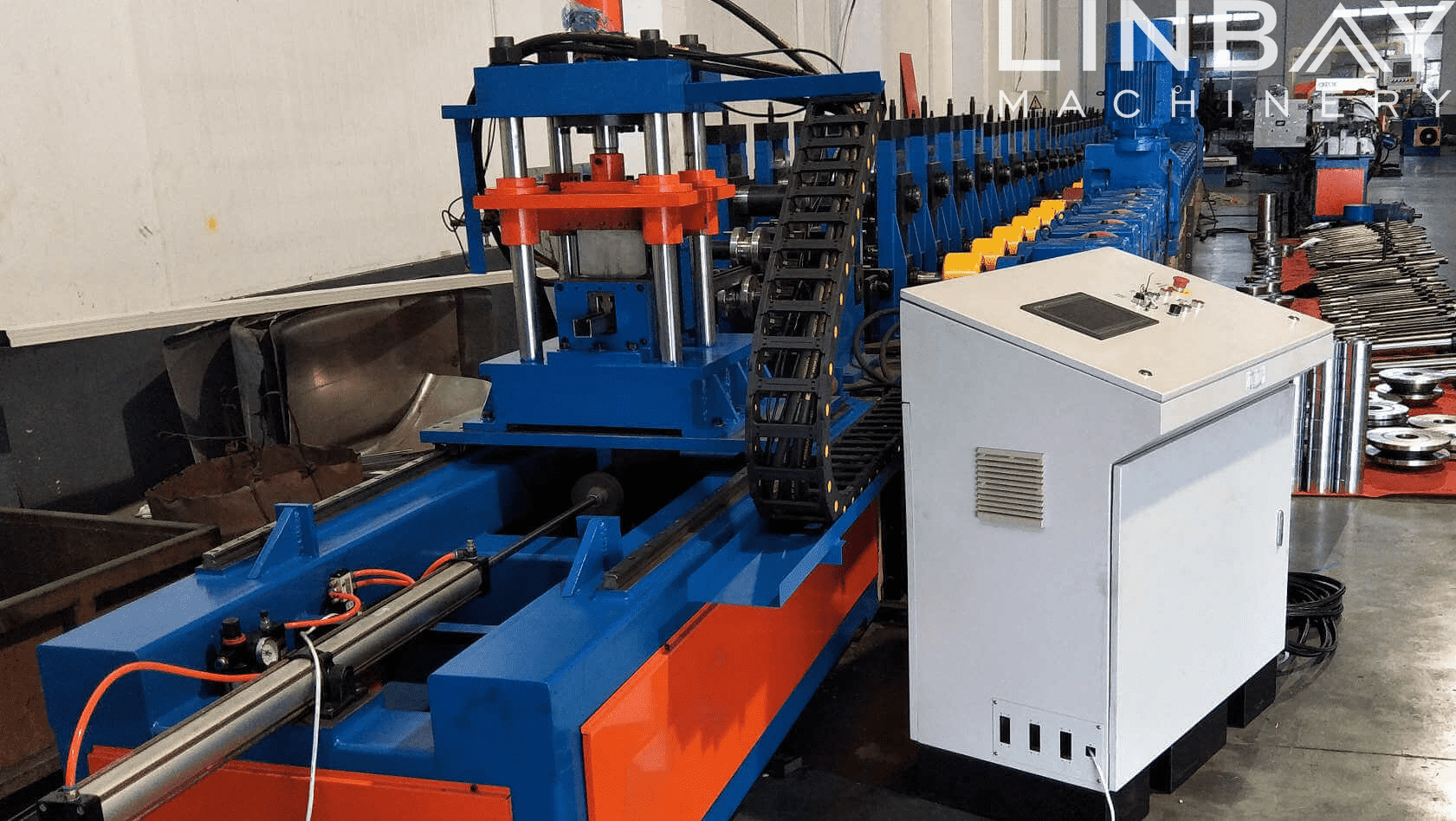

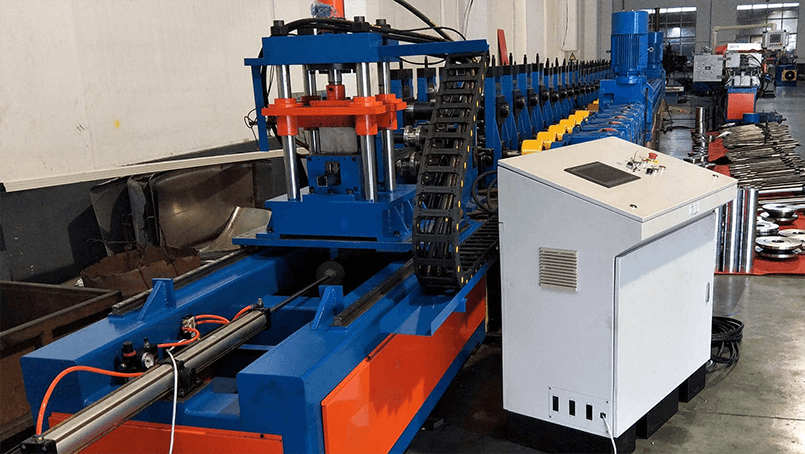

Machine details:

Normally we recommend our customers that one roll forming machine produce one size of octagonal tube.

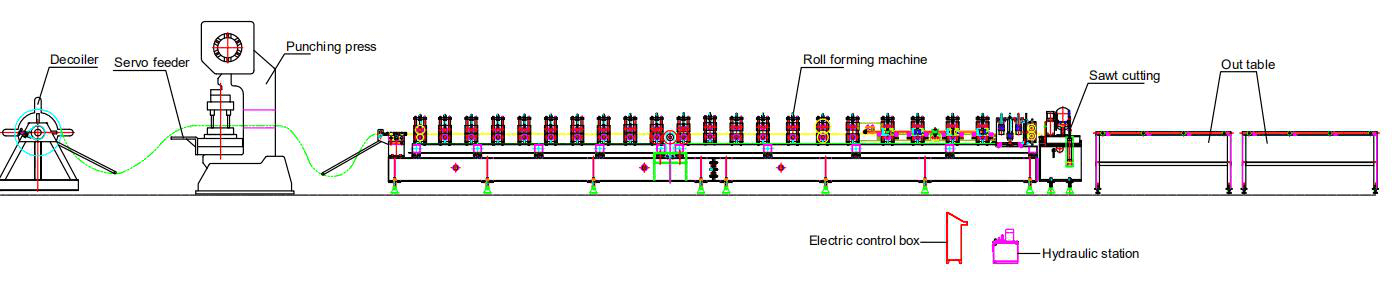

Flow chart:

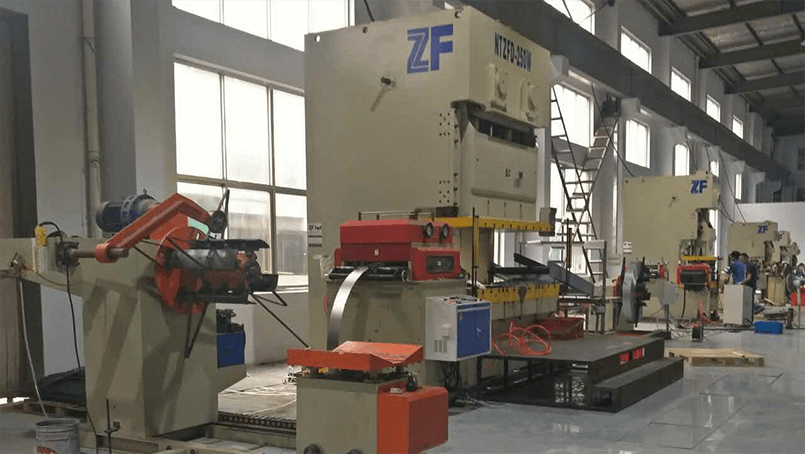

3T Manual decoiler-Hydraulic punch-Roll forming machine-Saw cut-Out table

Application

Technical Specifications

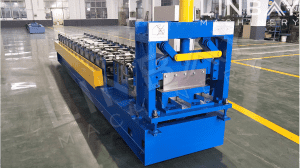

More Pictures

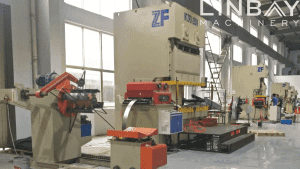

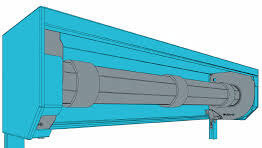

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

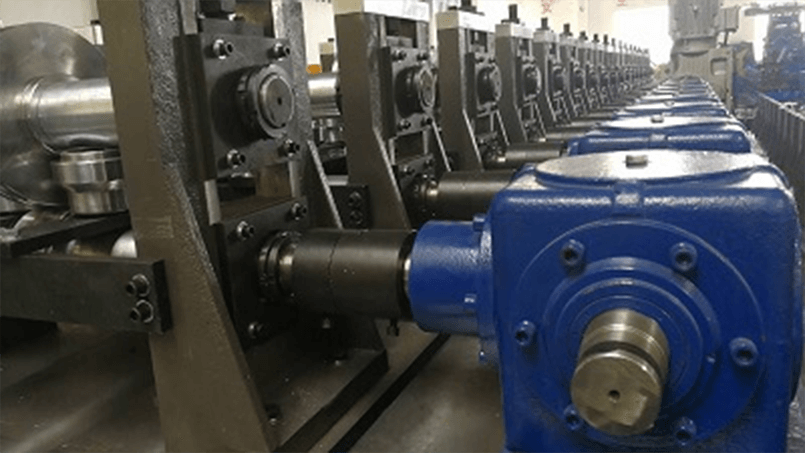

5. Driving system

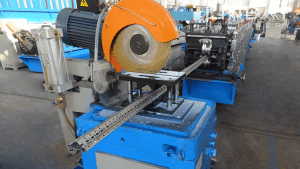

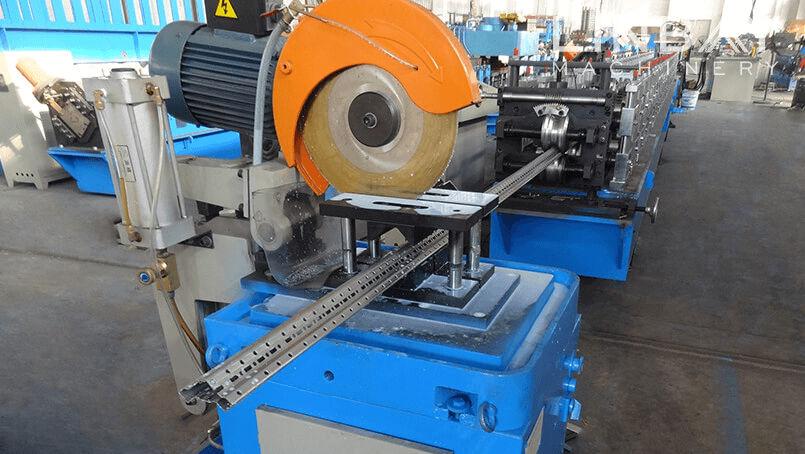

6. Cutting system

Others

Out table

Send your message to us:

Write your message here and send it to us

Write your message here and send it to us