It adheres for the tenet “Honest, industrious, enterprising, innovative” to create new products consistently. It regards buyers, success as its own success. Let us develop prosperous future hand in hand for OEM China China PPGI Roof Panel Wall Panel Roll Forming Machine Profile Sheet Making Machine, The continual availability of high grade solutions in combination with our excellent pre- and after-sales services ensures strong competitiveness in an increasingly globalized market place.

It adheres for the tenet “Honest, industrious, enterprising, innovative” to create new products consistently. It regards buyers, success as its own success. Let us develop prosperous future hand in hand for China Roll Forming Machine, double layer roof forming machine, downspout pipe roll forming machine, downspout pipe round, downspout pipe square, gutter roll former, K span, K span MIC 120, ridge cap production line, roof tile cold bending machine, Standing Seam Roll Forming Machine, Tile Machine, trapezoidal wall panel roll forming machine, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

Description

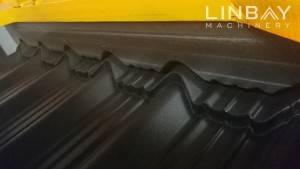

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

Technical Specifications

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):0.3-0.8 |

|||

|

Yield strength: 250 – 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

10-25 |

Or according to your requirement |

|

3 |

Forming station |

20-23 |

According to your profile |

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Chain drive |

Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Wall panel station |

Forged Iron station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

Flow Chart

Manual decoiler–feeding–roll forming–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

High reputation Changge Gf32 Rolling Pipe Bendi...

-

PriceList for China Fully Automatic Highway Gua...

-

Hot New Products China High Quality Slitting Li...

-

Good User Reputation for China Wave Roof Tile P...

-

Factory Cheap Hot China Double Layer Metal Colo...

-

ODM Supplier China Stud & Track Roll Formi...