“Based on domestic market and expand overseas business” is our development strategy for OEM Factory for China Constrution Scaffolding Working Platform Steel Plank Roll Forming Machine Manufacturer, With our rules of ” small business status, partner trust and mutual benefit”, welcome all of you to definitely get the job done jointly , mature jointly.

“Based on domestic market and expand overseas business” is our development strategy for China Forming Machine, iron scaffold plank machine, Roll Forming Machine, scaffold board rolling machine, scaffolding foot plate machine, scaffolding plate making machine, Scaffolding Platform machine, Scaffolding Platform making machine, With the goal of “zero defect”. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

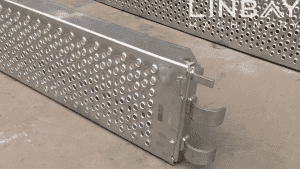

Description

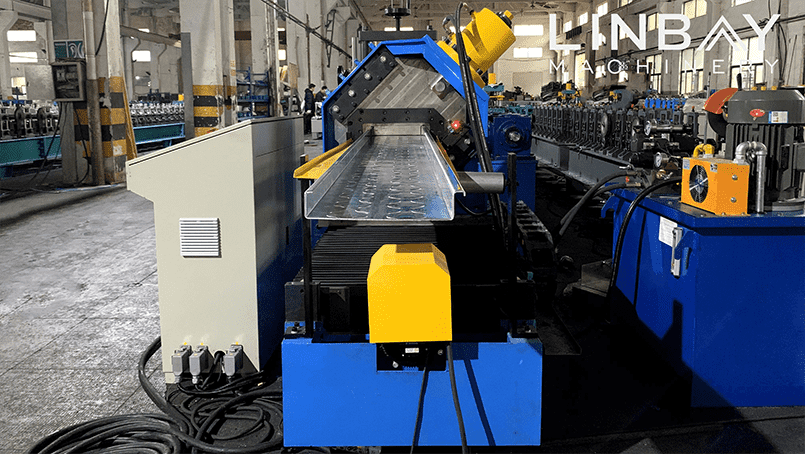

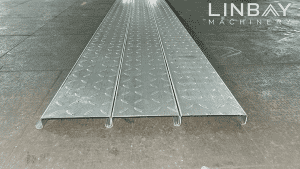

Scaffold plank roll forming machine can make scaffold plank. We adopt servo feeder to make sure the holes are in high precision. We use punching press to make line speed faster and we use hydraulic post cutting to make sure the profile perfect.

The thickness of raw material is around 1-2mm.

Application

Technical Specifications

Flaw Chart

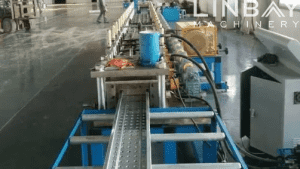

Manual decoiler–feeding–hydraulic punching station–forming machine–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

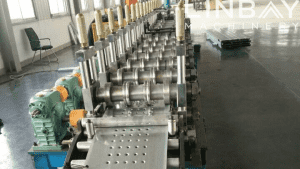

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table