Description

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

Technical Specification

Flow Chart

Manual decoiler--feeding--forming machine--hydraulic cutting--out table

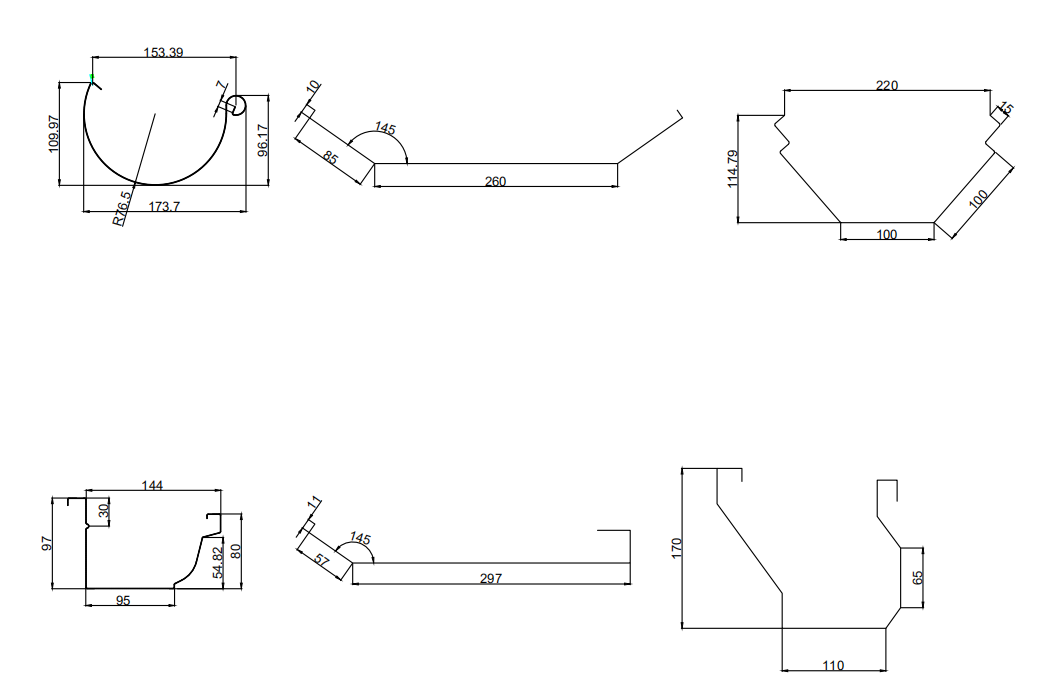

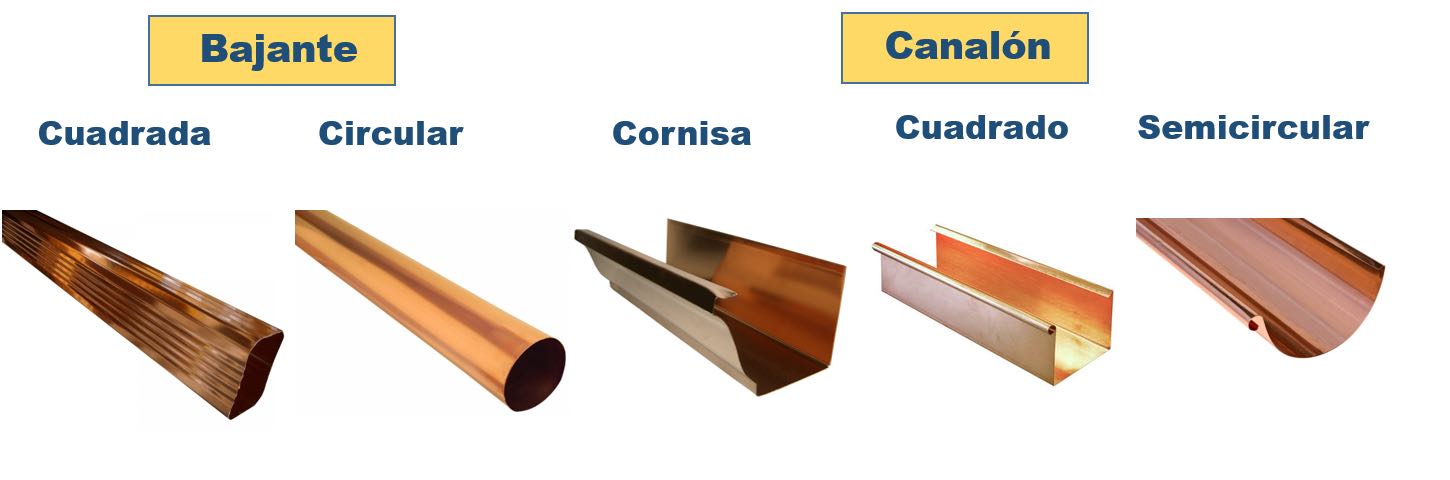

Perfiles

Aplicacion

Fotos De Detalles

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

Write your message here and send it to us

Write your message here and send it to us