Description

This C/U Purlin Roll Forming Machine, can produce C shape and U shape purlins from 100-400mm of width and easily to change spacers. Maximum thickness can be formed at 4.0-6.0mm.

Also we can design this machine to work with any width of the purlins and main channels, automatically adjustable by PLC control or adjust handle wheel to change the sheet width. This is much more easily than adjust the spacers and can save more time. Regarding the cutting unit ,you can choose the pre-cut or post cut.The driving system we adopt the gimbal system if the raw material is thicker than 2.5mm,this is much more strong driving power and more stable when forming the purlins.

Technical Specification

Flow Chart

Manual decoiler--feeding--forming machine--hydraulic cutting--out table

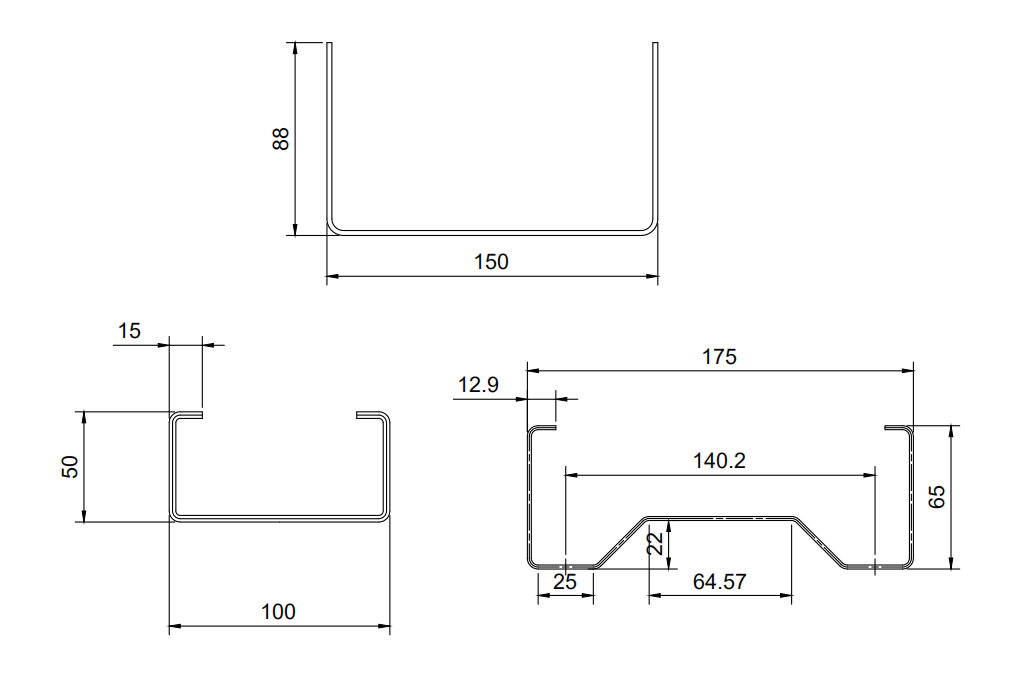

Perfil

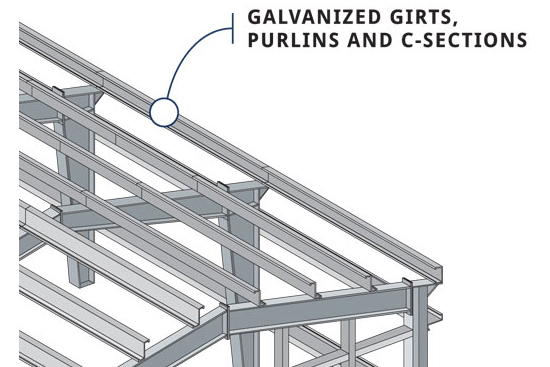

Applicacion

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table