We know that we only thrive if we could guarantee our combined price competiveness and high quality advantageous at the same time for PriceList for China Fully Automatic Highway Guardrail Roll Forming Machine, Now we have been in operation for more than 10 years. We’re dedicated to top quality items and consumer help. We invite you to go to our corporation for a personalized tour and advanced organization guidance.

We know that we only thrive if we could guarantee our combined price competiveness and high quality advantageous at the same time for China Liming Roll Forming Machine, crash barrier roll forming machine, Guardrail Forming Machine, guardrail machine, guardrail machine manufacturers, guardrail machine suppliers, Guardrail Roll Forming Machine, highway guardrail machine, Highway Guardrail Roll Forming Machine, Highway protection fence making machine, Highway safety fence machine, Light Gauge Steel Roll Forming Machine, W-Beam machine, W-Beam roll forming machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We have been willing to cooperate with business friends from at home and abroad and create a great future together.

Description

We had experience of Russian type Guardrail, there are four lines totally:① two wave guardrail roll forming machine, ② U post roll forming machine,③ connection punching line and ④end wind punching line.

This U Roll Forming Machine can be designed for thickness 4-5mm, it is widely used as post of guardrail. We use forged iron stands(see picture) and gearbox driving to make sure this machine can longly work in a stable situation.

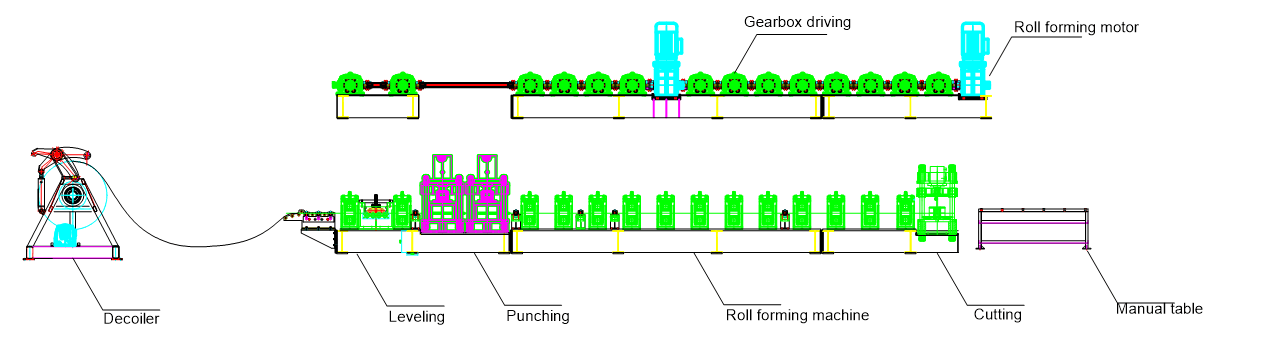

The flow chart of U post roll forming machine:

Hydraulic decoiler-Leveling-Punching-Roll forming machine-Cutting-Out table

Technical Specifications

More Pictures

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table