carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Professional China High Speed Fully Automatic Heavy Duty Steel Perforated Cable Tray Roll Former, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We invite you to visit our company for a personalized tour and advanced business guidance.

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Angular Ladder Type Cable Trays, Cable Ladder Horizontal, Cable Ladder Standard, Cable Ladder Straight, cable tray ladder type, gi ladder cable tray, Hot dip galvanised cable ladder, ladder cable tray, ladder tray, Perforated Cable Trays, Perforated Metal cable ladder, POWERWAY CABLE LADDER, Standrad duty cable ladder, Steel Ladder Cable Trays, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

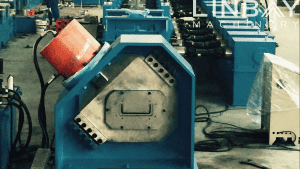

Description:

Automatic Cable Tray Roll Forming Machine is widely used in power and communication system. We have experience of making roll forming machine for Australian type cable tray and Italian type cable tray. Also we can make Din Rail Roll Forming Machine and Box Board Roll Forming Machine according to your drawing. This cable tray forming machine can adjust the working width easily by PLC automatically. Also we manually changing type as your wish.

Technical specification:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table