We usually believe that one’s character decides products’ high quality, the details decides products’ excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Quality Inspection for High Speed Guardrail Roll Forming Machine W Shaped Highway Guardrail Making Machine, We sincerely hope to provide both you and your small business with a excellent start. If there is anything we are able to do for yourself, we shall be more than pleased to do so. Welcome to our manufacturing facility for go to.

We usually believe that one’s character decides products’ high quality, the details decides products’ excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for China highway guardrail roll forming machine, Highway Guardrail Forming Machine, highway guardrail making machine, highway guardrail roll former, highway guardrail W beam forming machine, Price highway guardrail roll forming machine, Thrie beam making machine, We now have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export merchandise to other countries. We expect to cooperate with you to develop a larger market.

Description:

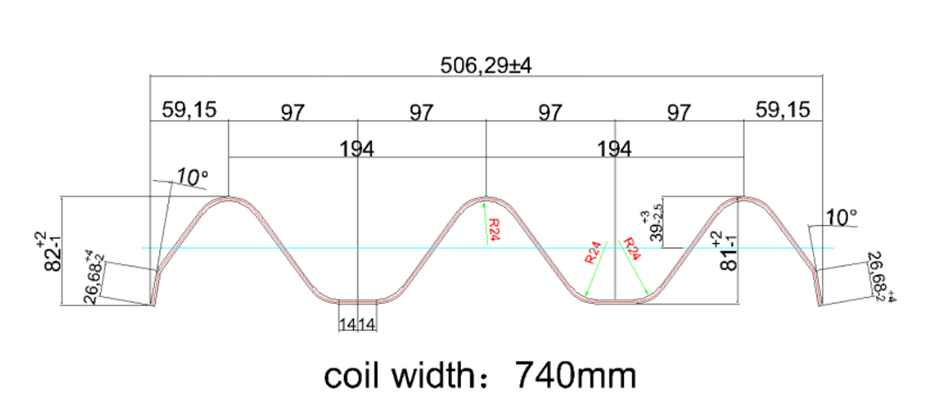

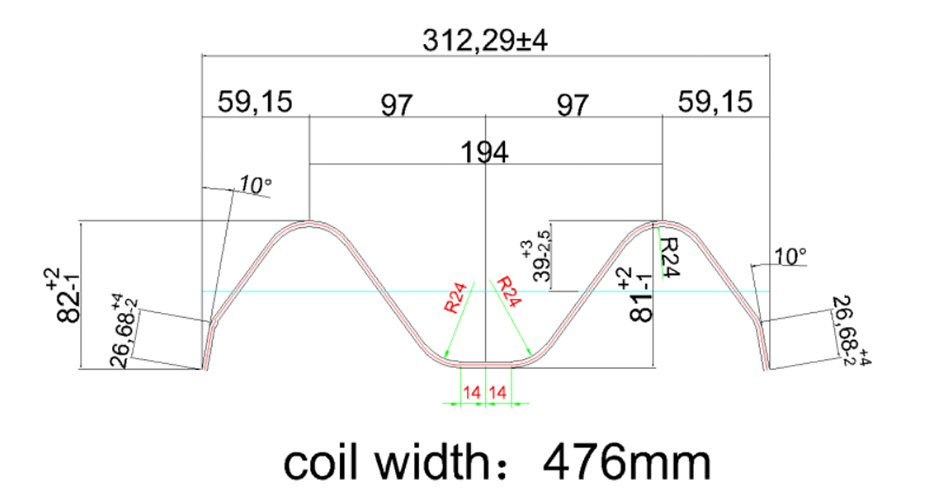

This Highway Guardrail Roll Forming Machine can be designed as two waves or three waves profiles in one machine just need to add some stations at the end of the machine. We adopt the universal joint driving system. The Max.thickness can reach at 4.0mm.

Profile:

Technical specification:

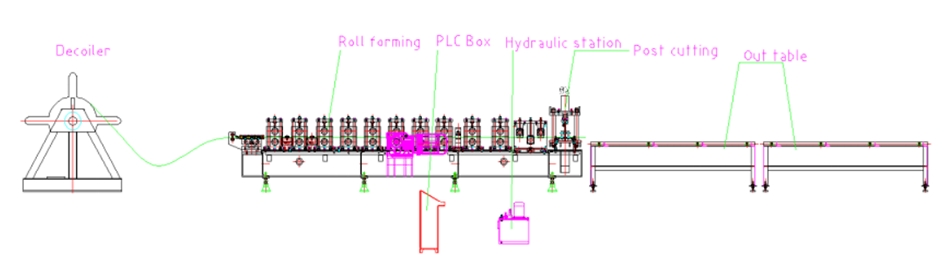

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table