Our mission would be to grow to be an innovative provider of high-tech digital and communication devices by offering benefit added style, world-class production, and repair capabilities for Renewable Design for China Two or Three Waves Hydraulic Highway Guardrail Making Machine Cold Roll/Rolling Making Forming Machinery, We have more than 20 years experience in this industry, and our sales are well trained. We can give you the most professional suggestions to meet your products’ requirements. Any troubles, come to us!

Our mission would be to grow to be an innovative provider of high-tech digital and communication devices by offering benefit added style, world-class production, and repair capabilities for China Roll Forming Machine, crash barrier roll forming machine, Forming Machine, Guardrail Forming Machine, guardrail machine, guardrail machine manufacturers, guardrail machine suppliers, Guardrail Roll Forming Machine, highway guardrail machine, Highway Guardrail Roll Forming Machine, Highway protection fence making machine, Highway safety fence machine, W-Beam machine, W-Beam roll forming machine, Our objective is “to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us”. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Description:

This Highway Guardrail Roll Forming Machine can be designed as two waves or three waves profiles in one machine just need to add some stations at the end of the machine. We adopt the universal joint driving system. The Max.thickness can reach at 4.0mm.

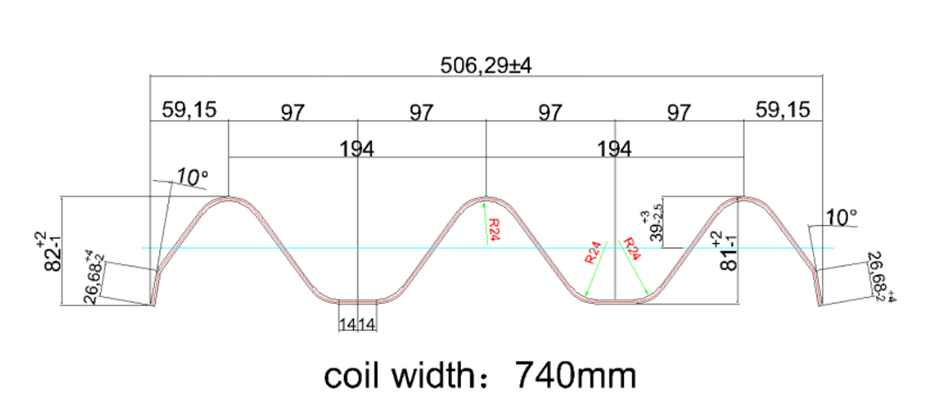

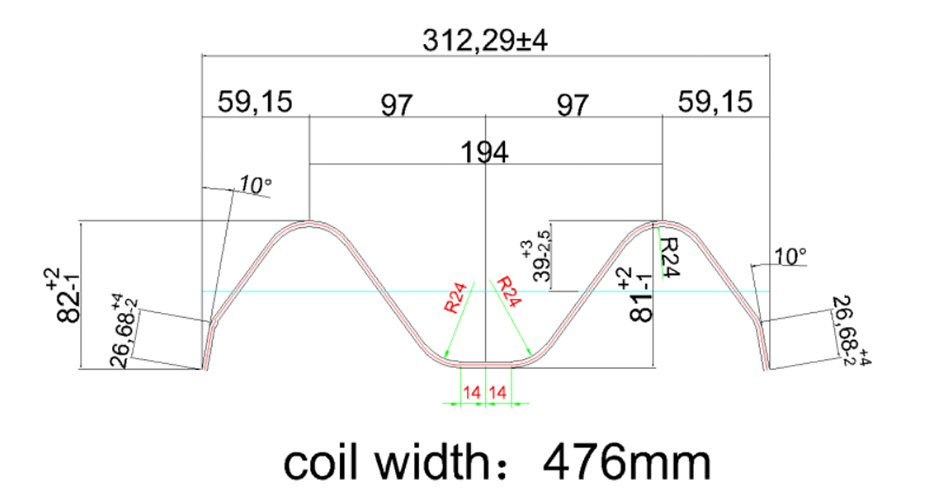

Profile:

Technical specification:

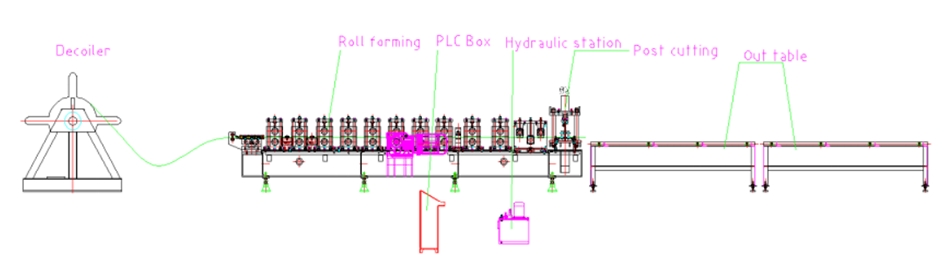

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table