Description

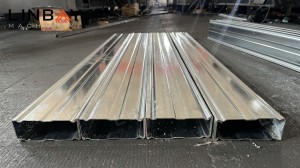

This Ridge Cap roll forming machine is used in roofing sheet. The normal raw material is 0.3-0.8mm thickness. Normal working speed is 10-25m/min. It has many different shapes, we can make all kinds of machine if you can offer the profile to us. We are very profesional in OEM roll forming machine.

Technical Specifications

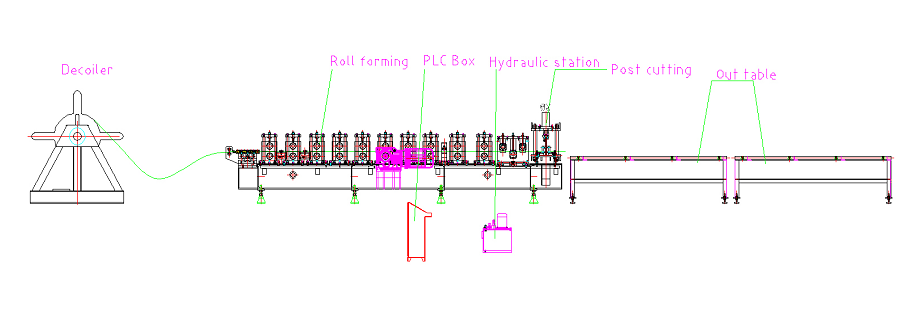

Flow Chart

1. Decoiler

2. Feeding

3.Punching

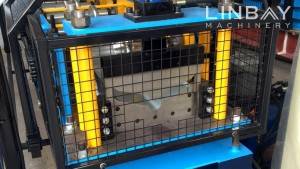

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

Write your message here and send it to us

Write your message here and send it to us