Description

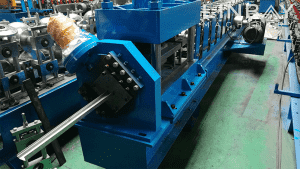

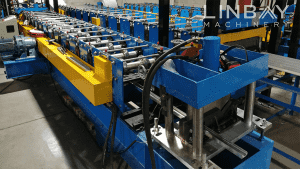

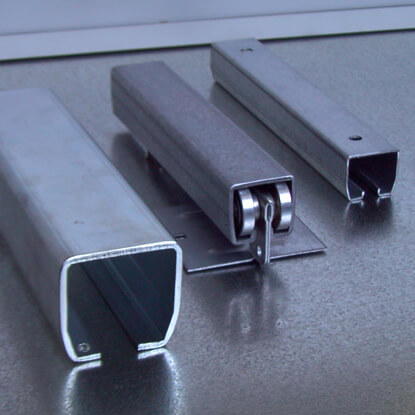

Rail Roll Fomring Machine includ Door Rail Roll Fomring Machine, Solar Rack Roll Forming Machine, Guide Rail Roll Forming Machine etc. The working thickness can be 1.5-2.5mm. The Max. working speed can be 25m/min.

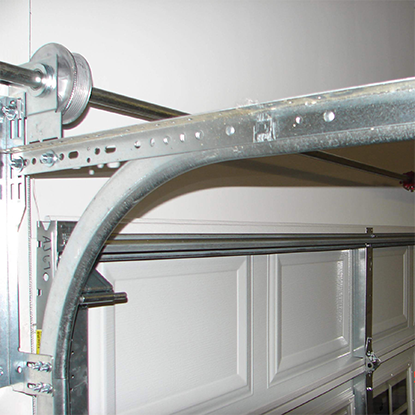

We have exported one door rail roll forming machine to Argentina. We can make curve door rail like picture showed. We recommend gearbox driving system and flying shear system to keep our machine work with high speed.

Application

Technical Specifications

Flow Chart

Manual decoiler--leveling--forming machine--hydraulic cutting--out table

1. Decoiler

2. Feeding

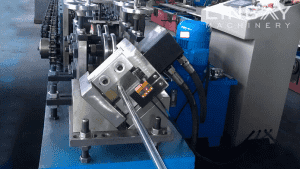

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

Write your message here and send it to us

Write your message here and send it to us