vhidhiyo

Profile

Mutsetse wekugadzira uyu unogona kuburitsa saizi dzakasiyana dzeC-mhando, Z-mhando, uye M-mhando purlins ine dhigirii repamusoro re automation. Icho chinodhura-chinoshanda chekudyara sarudzo.

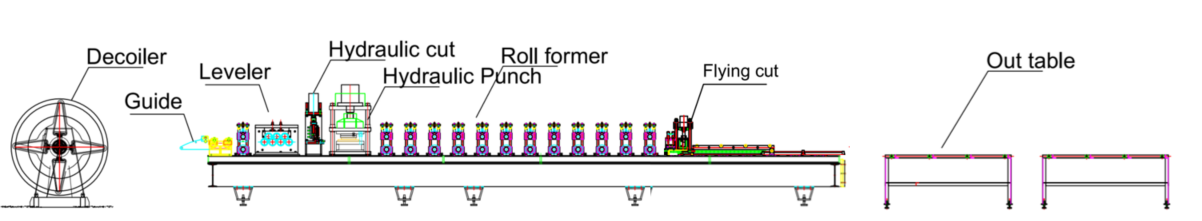

Flow chati

Decoiler

Isu tinoisa apress-ruokopane decoiler kubata simbi coil panzvimbo painochinja coils, kudzivirira kamwe kamwe kusunungurwa uye zvinogona kukuvadza vashandi. Uyezve,simbi inodzivirira mashizhaakaiswa kudzivirira kutsvedza kwecoil panguva yekusunungura. Iyi dhizaini haingo chengetedza simbi coil uye muchina asiwoinochengetedza kuchengeteka.

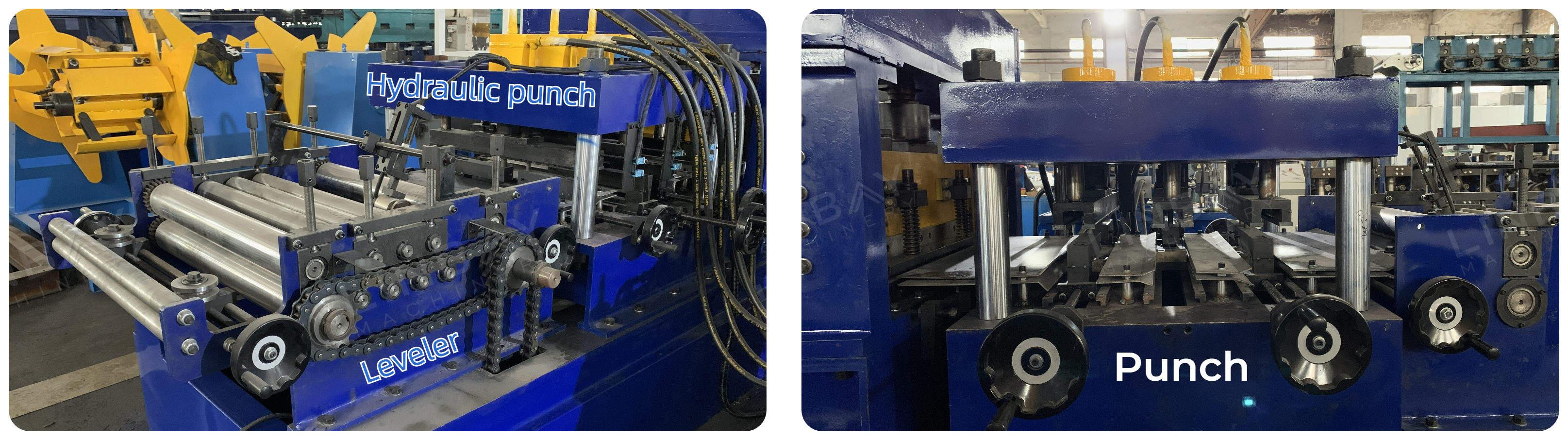

Guiding&Leveler

Guiding rollers chengeta coil yesimbi nemichina iri panzvimbo imwechete-mutsara kuendakudzivirira kukanganisayemaprofayiri akaumbwa. Multiple guiding rollers akaiswa zvine hungwaru pamwe chete nemutsetse wese wekugadzira. Uye zvino, iyo coil yesimbi inopinda muzinga, iyoinobvisa chero zvisizvo, inosimudzira flatness uye parallelismyesimbi coil. Izvi, zvakare,inovandudza kunakayezvose zviri zviviri coil uye yekupedzisira purlin chigadzirwa.

Hydraulic punch

Iyo hydraulic punching muchina inouya nemapoka matatu ekufanemasilinda emafuta anowirirana. Izvi zvinogona kufanokukurumidza uye nyoreyakagadziridzwa kusangana nezvinodiwa nevatengi, ichipakuchinjika kwakanakisa. Iyo die changeover process inoshanda uye inopedzwa mukati5 maminitsi.

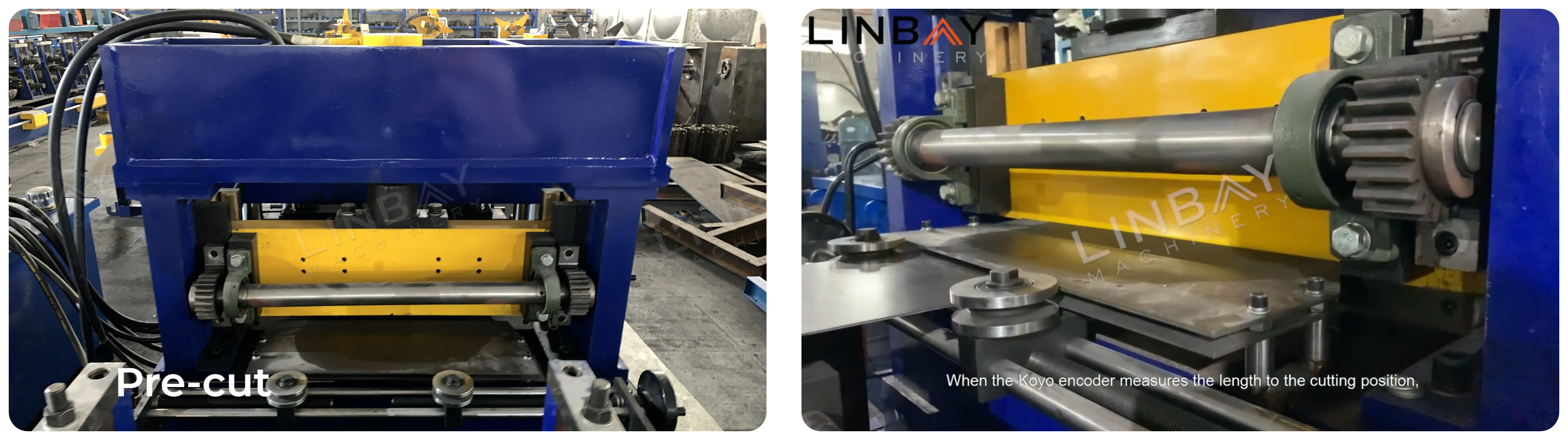

Pre cutting

Kugonesa kutsiva nyore kweakasiyana coil upamhi hwekugadzira hukuru hwakasiyana uye kuchengetedza zvinhu zvakasvibirira, pre-kucheka mudziyo wakagadzirirwa kushanda zvakanaka,kuderedza marara.

Leveler, punching muchina uye muchina wekucheka zvakabatanidzwa nemuchina wekugadzira roll, unova wakanyanyadhizaini inodhura.

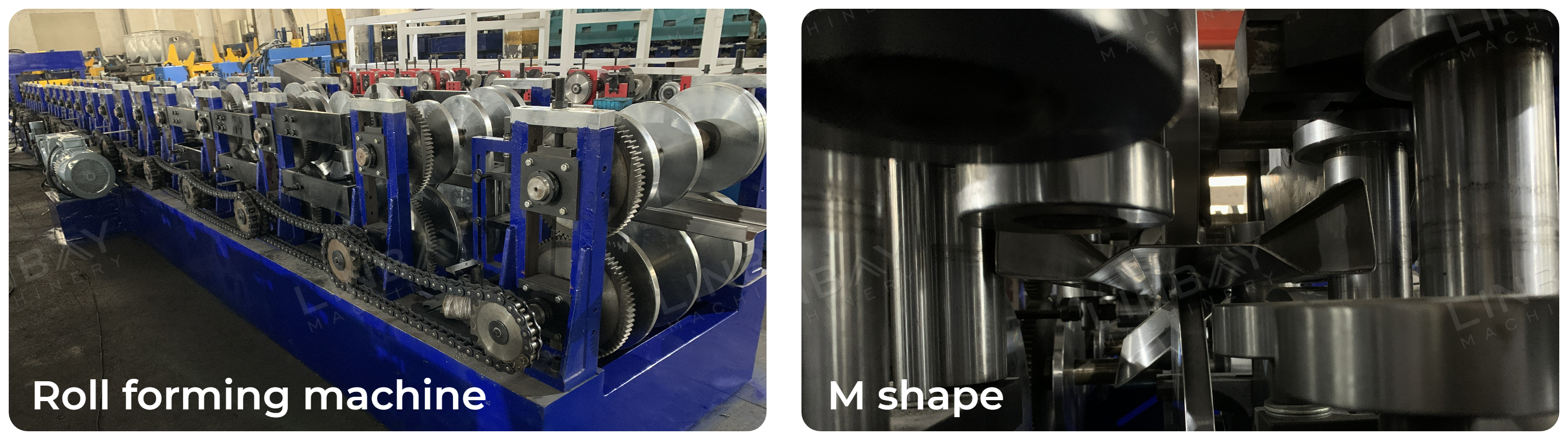

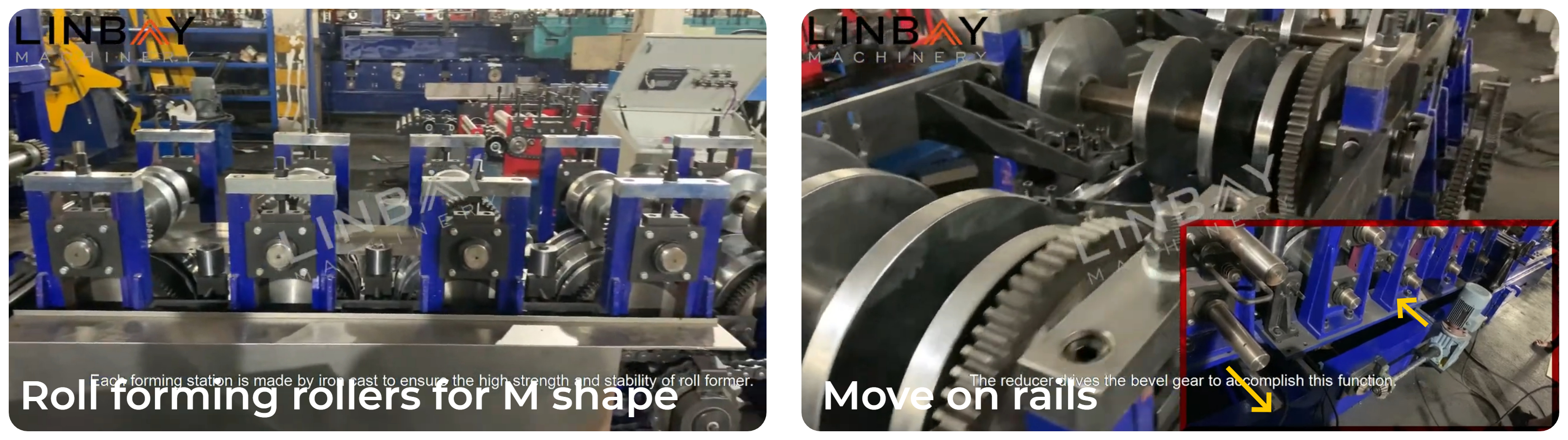

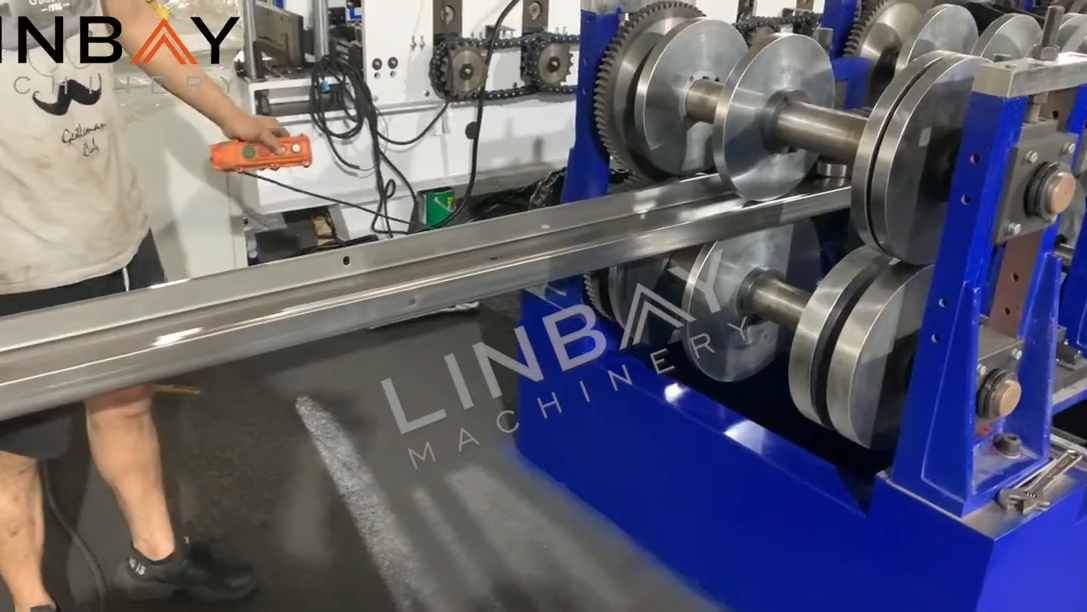

Roll former

Muchina wekugadzira roll unoratidza acast-iron structureuyecheni yekutyaira system. Chimiro chesimbi-simbi ndeyesimbi yakasimba, kuve nechokwadi chekusimba uye kugadzikana. Muchina uyu unokwanisa kugadziraC, Z, uye Sigma purlins. Iwo mana ekutanga roller anoshandiswa kune Sigma chimiro, uye anosimudzwa kana achigadzira C kana Z maumbirwo. Uyezve, nekutenderera nemaoko2-3 kugadzira zviteshi ne180 °, unogona kushandura pakati pekugadzira C uye Z purlins. Zviteshi zvekugadzira kune rimwe divi remuchina zvinofamba panjanji kugadzira purlins yehupamhi hwakasiyana. Izvo zvakakosha kuti uzive kuti, pakukumbira, tinogona zvakare kugadzira purlin michina inosiyana mukatizvose kureba nehupamhi hwepasipanguva imwe chete.

Hydraulic station

Yedu hydraulic station yakarongedzerwa neinotonhora fan inobatsira kuchengetedza yakakwana tembiricha yekushanda, kuve nechokwadi.kuwedzera kushanda zvakanakapanguva yekuenderera mberi kwekushanda.

Encoder&PLC

Vashandi vanogona kudzora muchina kuburikidza nePLC skrini, kugadzirisa kugadzirwa speed, kuseta zviyero zvekugadzira, uye kureba kwekucheka, nezvimwe. Encoder inosanganiswa mumutsara wekugadzira, ichishandura kureba kwesimbi coil kuita masaini emagetsi anoendeswa kune PLC control panel. Izvi zvinobvumira muchina wedu kuchengetedzakutema chaiko mukati me1mm, kuvimbisa zvigadzirwa zvemhando yepamusoro uyekuderedza kutambisa zvinhunekuda kwekucheka kukanganisa.

Isu tinopa masevhisi ekugadzirisa, anosanganisira asi asina kuganhurirwa kune mota modhi, mhando, zvemagetsi chikamu mabhureki, uye PLC control panel mutauro.

1. Decoiler

2. Kudyisa

3.Kubaya

4. Roll forming stands

5. Driving system

6. Kucheka hurongwa

Vamwe

Out table