vhidhiyo

Profile

Muchinjikwa bracing inoita basa rakakosha mumarekeni masisitimu, kusimbisa rutsigiro uye kugadzikana pakati pemafuremu maviri akatwasuka. Yakagadzirwa kubva kusimba dema simbi ine ukobvu kazhinji kubva 1.5 kusvika 2.5mm, post-kuumba pendi application inoshanda kuwedzera ngura uye kusaita ngura, kuve nechokwadi chehupenyu hurefu uye kuvimbika.

Chaiyo kesi-Main Technical Parameters

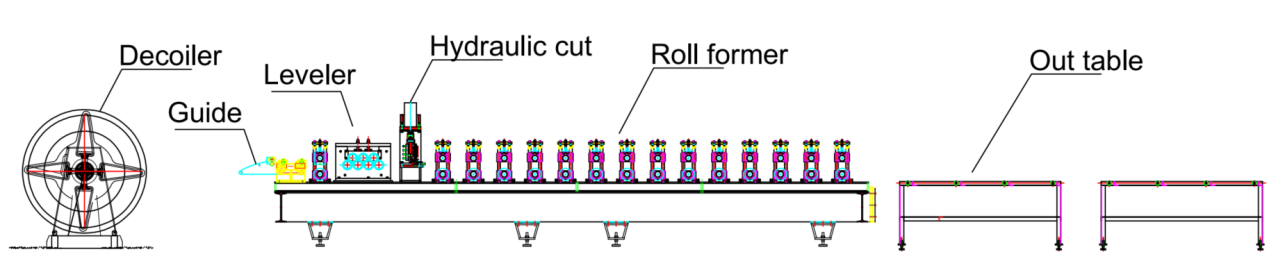

Inoyerera chati: Decoiler--Kutungamira--Leveler--Pre cut--Roll fomumuchina--Kunze tafura

- 1.Mutsara wekumhanya: 0-15m / min, inogadziriswa

- 2.Dimensions mune chaiyo kesi: Multiple upamhi 80-300mm, yakatarwa kureba 50mm

- 3.Suitable zvinhu: Galvanized steel

- 4.Material ukobvu: 1.5-2mm

- 5.Roll kugadzira muchina: Cast-iron chimiro uye cheni yekutyaira system

- 6.Cutting system: Cheka usati waita roll kugadzira muchina, ine hydraulic simba.

- 7.PLC cabinet: Siemens system.

Chaiyo kesi-Michina

1.Decoiler*1

2.Leveler(Akashongedzerwa pamupumburu wekugadzira muchina)*1

3.Hydraulic pre-cut machine*1

4.Roll kugadzira muchina*1

5.Kunze tafura*2

6.PLC control cabinet*1

7.Hydraulic station*2

8.Spare parts box(Mahara)*1

Nyaya chaiyo-tsanangudzo

- Decoiler

Kazhinji, iyo decoiler inoshanda sechinhu chekutanga chemutsetse wekugadzira. Ruoko rwayo rwekudzvanya runokwanisa kuchengetedza coil yesimbi, kudzivirira kukuvara kubva kucoil recoil panguva yekuchinja kwecoil. Ekunze coil retainer midziyo inowedzera kudzivirira makoiri kubva pakutsvedza kubva mandrel.

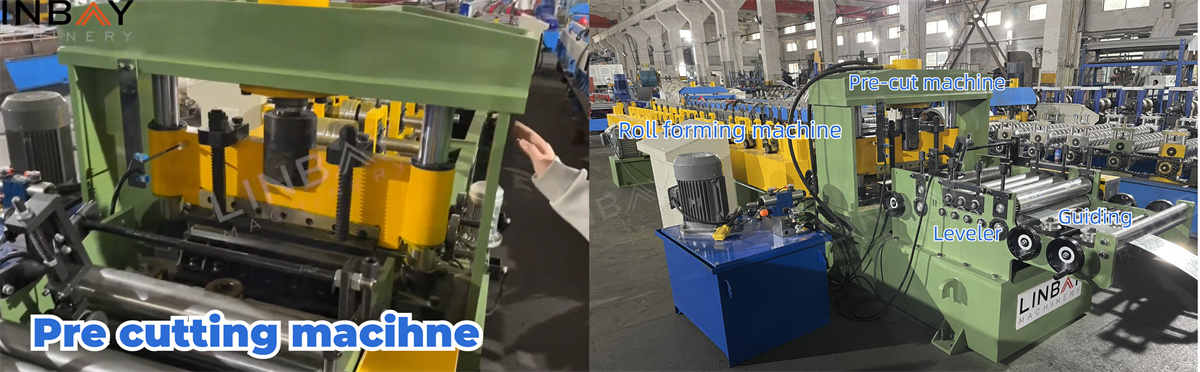

Kutungamira

Iwo anotungamira ma roller anotungamira zvakanaka coil yesimbi mumarongerwo ekugadzira kuchengetedza kurongeka pakati pesimbi coil uye roll yekugadzira muchina, ichideredza chero ingangoita kubhenda kana kutsauka.

Leveler

Ukobvu hwemuchinjikwa bracing hunosvika 2.5mm, uye chete kana yakanyatsotwasuka uye isina kumonyoroka inogona kupa kugadzikana kwakanyanya kweiyo rack frame. Muchina wekuenzanisa unogona kudzikamisa coil yesimbi, kusunungura kumanikidza kwemukati, zvichiita kuti zvive nyore kuumba uye kuumba zvakananga. Mune iyi mutsara wekugadzira, muchina wekuyera wakaiswa pamutsetse wekugadzira muchina base, unogona kuchengetedza nzvimbo yepasi uye kuderedza mitengo yevhu.

Pre-cut machine

Kuenzaniswa ne-post-kucheka, kufanocheka usati wagadzira hakuna kutambisa. Mhinduro iyi inogonesa kutsiviwa kwesimbi koiri yehupamhi hwakasiyana-siyana kugadzira hukuru hwakawanda pamutsara wakafanana wekugadzira, pasina kukonzeresa chero tsvina.

Roll fomumuchina

Muchina wekugadzira roll ndiyo inonyanya kukosha chikamu chese mutsara wekugadzira. Inoshandisa chivakwa chakasimba chekukandira-simbi yechiteshi chekugadzira, chakagadzirwa kubva pachidimbu chesimbi. Kutenderera kwekugadzira rollers kunotungamirirwa neketani system.

Izvo zvinhu zvekugadzira rollers iGcr15, yakakwira-kabhoni chromium inotakura simbi inozivikanwa nekuomarara kwayo uye kusapfeka. Iwo ma roller ane chrome-akaputirwa kuti awedzere hupenyu hwavo hwesevhisi. Iwo mashaft akagadzirwa ne40Cr zvinhu uye anorapwa kupisa.

Reinforcements inosanganiswa pazasi peprofile kuti iwedzere simba rayo. Muchina wekugadzira mupumburu uyu unogona kugadzira kuchinjika bracing nehupamhi hwe80-300mm uye kureba kwe50mm. Nekuisa zviyero zvinodiwa muPLC control panel, chiteshi chekugadzira chinofamba nenjanji kuenda kunzvimbo chaiyo uye chaiyo. Iyo yekuumba poindi inogadzirisawo sezvo chiteshi chekugadzira chinofamba.

Nekuchengetedza kwekufamba kwekugadzira zviteshi, 2 kureba sensors dzakaiswa pachigadziko chemuchina, inofambirana nenzvimbo dzekunze nedzemukati-kati izvokuumbachiteshisinogona kutamisirwa ku.Kune masensa, tnzvimbo yaanonzwa ndiyoherepahwaro hwezviteshi zvekuumba. Mukati-katisensorndiko kudzivirirakuumbachiteshiskubva pakuswedera pedyo zvakanyanya uye kukonzera kudhumhana kwema roller.Wekunzesensorndiko kudzivirirakuumbachiteshi kubva pakusiya kubva kunjanjiuye kuwa.

Hydraulic station

Iyo hydraulic station inouya yakashongedzerwa mafeni ekutonhodza akagadzirirwa kunyatsopisa kupisa, kuvimbisa kusakanganiswa kushanda uye kuwedzera chibereko. Inozivikanwa nekuderera kwayo mitengo yekutadza, iyi hydraulic station yakavakirwa kuti igare, ichiva nechokwadi chekugara kwenguva refu.

PLC control cabinet & Encoder

Iyo encoder inoshandura kureba kwakanzwika kwesimbi coil kuita masaini emagetsi anotumirwa kuPLC control cabinet. Mukati mekutonga kabati, kumhanya kwekugadzira, kuburitsa kwega kwega, kureba kwekucheka, uye mamwe ma parameter anogona kutarisirwa. Nezviyero chaizvo uye mhinduro kubva kune encoder, muchina wekucheka unogona kudzora zvikanganiso zvekucheka mukati me ± 1mm.

1. Decoiler

2. Kudyisa

3.Kubaya

4. Roll forming stands

5. Driving system

6. Kucheka hurongwa

Vamwe

Out table