vhidhiyo

Profile

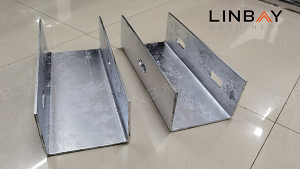

Strut chiteshi chinowanzo shandiswa mumashandisirwo akadai solar panel mounting, pombi dzemvura uye pombi, uye HVAC masisitimu. Standard strut chiteshi urefu hunosanganisira21mm, 41mm, 52mm, 62mm, 71mm, uye 82mm.Iyo dhayamita yekugadzira rollers inoshanduka nekureba kweiyo strut chiteshi, ine migero yakareba inoda mamwe ekugadzira zviteshi. Aya machaneli anowanzo gadzirwa kubvasimbi inopisa-yakakungurutswa, simbi inotonhorera, galvanized simbi, kana simbi isina tsvina,nekukora kubva12 geji (2.5mm) kusvika 16 geji (1.5mm).

Cherechedza: Nekuda kwekusimba kwegoho repamusoro resimbi isina tsvina, simba rekugadzira rinodiwa rakakura zvichienzaniswa nesimbi yakaderera-alloy uye yakajairwa kabhoni simbi yehukobvu hwakafanana. Naizvozvo, mipumburu yekugadzira michina yakagadzirirwa simbi isina tsvina inosiyana neiyo inoshandiswa kune yakajairwa kabhoni simbi uye galvanized simbi.

LINBAY inopa mitsara yekugadzira inokwanisa kugadzira mativi akasiyana, ayo akaiswa mumhando dzemanyorero uye otomatiki zvichienderana nehuwandu hweautomation inodiwa pakugadzirisa dimension.

Chaiyo kesi-Main Technical Parameters

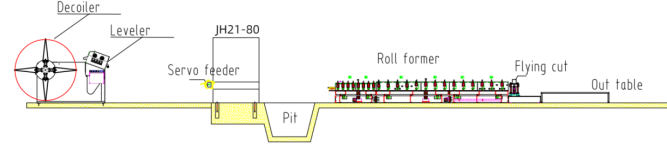

Inoyerera chati: Decoiler--Servo feeder--Punch press--Guiding--Roll forming machine--inobhururuka saw yekucheka--Out table

Chaiyo kesi-Main Technical Parameters

1.Mutsara wekumhanya: 15m / min, inogadziriswa

2.Suitable zvinhu:Simbi inopisa yakakungurutswa, simbi inotonhora, galvanized steel

3.Material ukobvu: 1.5-2.5mm

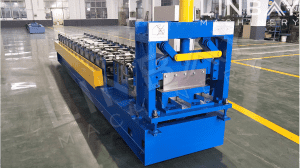

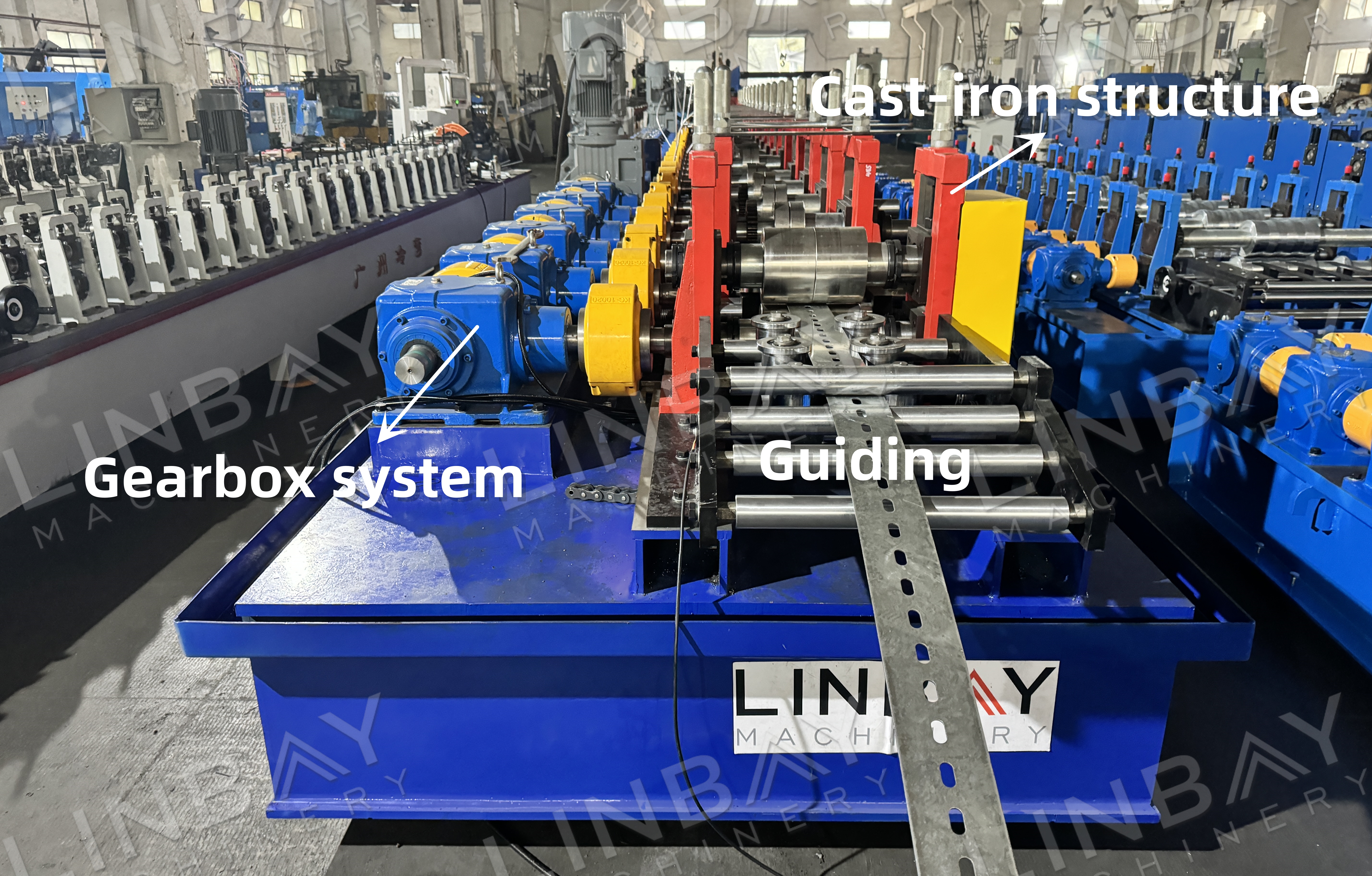

4.Roll kugadzira muchina: Cast-iron chimiro

5.Driving system: Gearbox driving system

6.Cutting system: Flying saw cutting. Roll kugadzira muchina haumire kana uchicheka

7.PLC cabinet: Siemens system

Chaiyo kesi-Michina

1.Hydraulic decoiler ine leveler*1

2.Servo feeder*1

3.Punch press*1

4.Roll kugadzira muchina*1

5.Flying saw cutting machine*1

6.PLC control cabinet*2

7.Hydraulic station*2

8.Spare parts box(Mahara)*1

Saizi yemudziyo: 2x40GP+1x20GP

Nyaya chaiyo-tsanangudzo

Decoiler ine Leveler

Muchina uyu unobatanidza mabasa e decoiler uye leveler, optimize floor space kushandiswa. Kukwirisa simbi makoiri akakora kupfuura 1.5mm kwakakosha, kunyanya kuenderera mberi nekurovera kwemaburi mumatanho e strut. Iyo leveler inovimbisa kuti coil yesimbi yakatsetseka uye inobvisa kushushikana kwemukati, kufambisa kuumbwa kuri nyore uye kuumbwa kwakatwasuka.

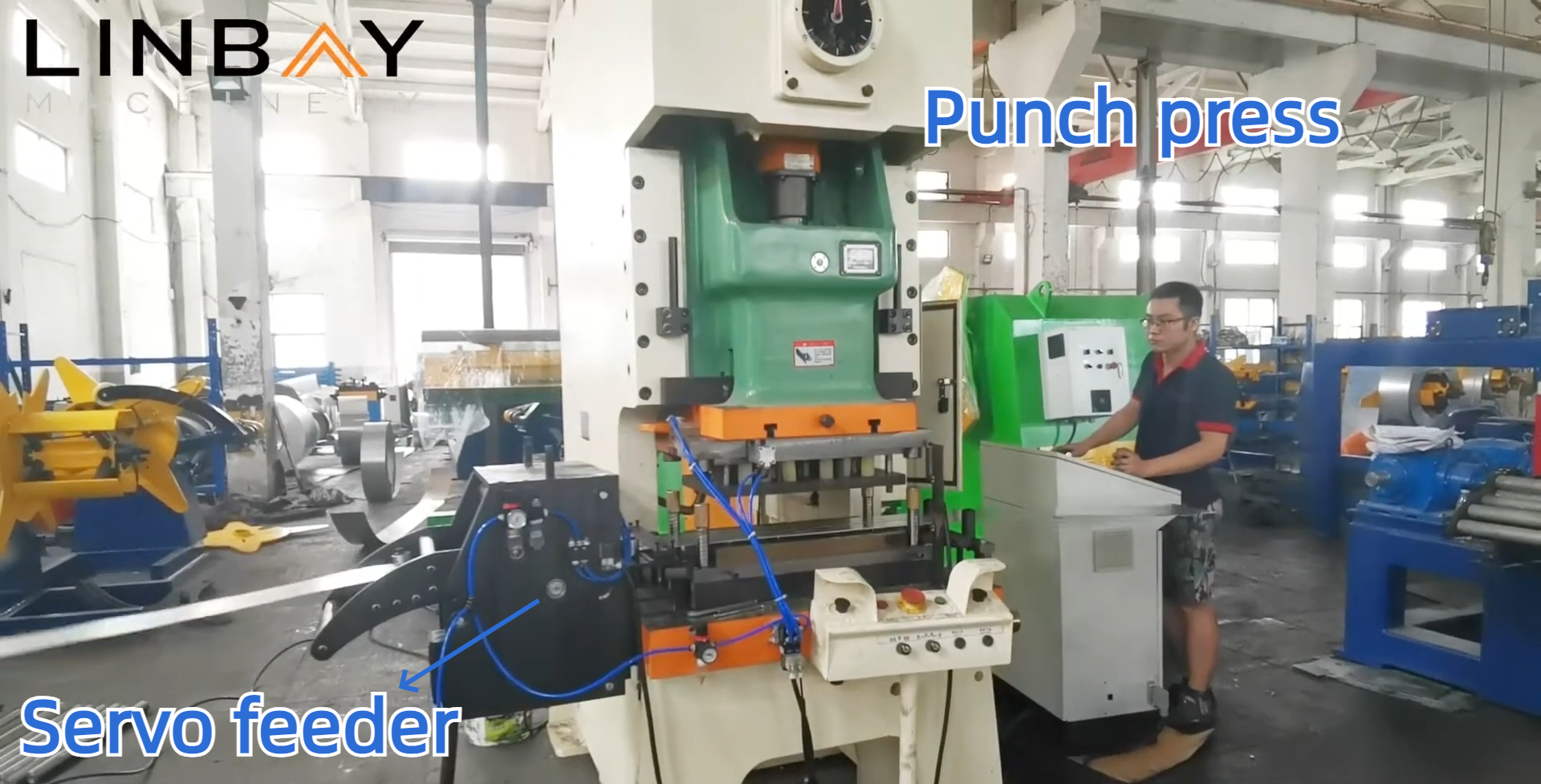

Servo Feeder

Servo feeder inopihwa zita rekushandisa kwayo servo mota. Nekuda kweiyo servo mota kushoma kwekutanga-kumisa kunonoka, inopa yakasarudzika chaiyo mukudyisa simbi coils. Uku kurongeka kwakakosha kuchengetedza kushivirira kwakasimba uye kuderedza simbi coil tsvina panguva yekugadzirwa kwe strut chiteshi. Pamusoro pezvo, zvisungo zvepneumatic mukati me feeder inosimudzira coil yesimbi ichichengetedza nzvimbo yayo kubva kumakwara.

Punch Press

Punch press inoshandiswa kugadzira maburi mucoil yesimbi, yakakosha pakuisa screws nenzungu kuchengetedza machani. Iyi punch press inoshanda nekukasira kupfuura yakasanganiswa hydraulic punch (yakaiswa pachigadziko chimwechete semuchina wekugadzira roll) uye standalone hydraulic punch. Isu tinoshandisa punch press kubva kune inozivikanwa yeChinese brand Yangli, iyo ine akawanda mahofisi epasi rose, kuve nechokwadi chiri nyore mushure mekutengesa sevhisi uye kuwana nyore kune dzimwe nzvimbo.

Kutungamira

Matunhu ekutungamira anochengeta coil yesimbi nemichina yakabatana padivi peiyo yepakati, kuve nechokwadi kutwasuka kweiyo strut chiteshi. Uku kurongeka kwakakosha pakufananidza mitsara ye strut nemamwe maprofile panguva yekumisikidza, ichikanganisa zvakananga kugadzikana kwese kwekuvaka chimiro.

Roll Kugadzira Machine

Iyo roll yekugadzira muchina inozvirumbidza yakakandwa-simbi chimiro chakagadzirwa kubva kune imwechete chidimbu chesimbi, ichipa kusimba kwakasiyana. Iwo ekumusoro neazasi rollers anomanikidza kuumba simbi coil, inotyairwa negiya bhokisi kuendesa simba rakakwana rekuita maitiro.

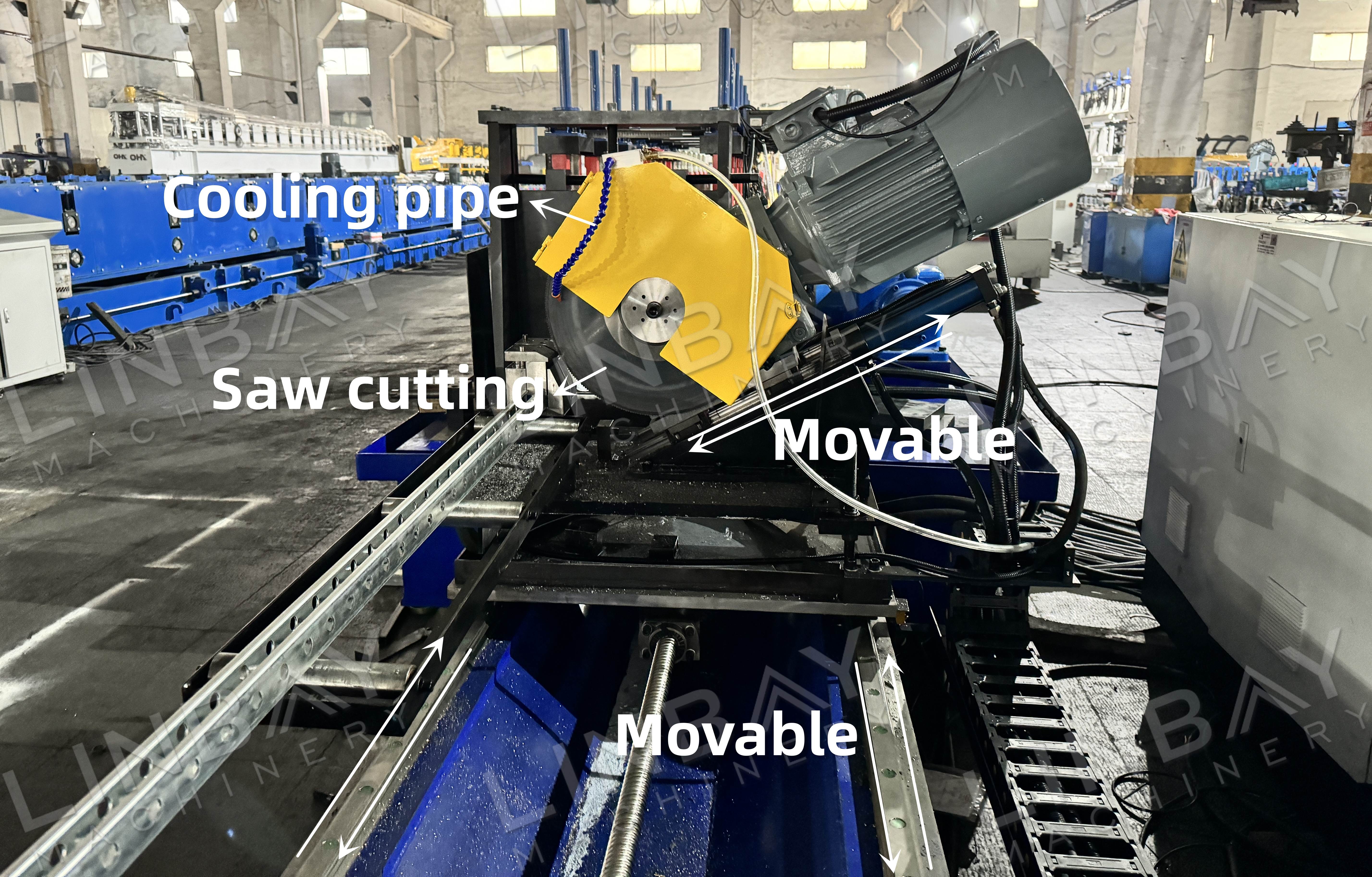

Flying Saw Kucheka

Ngoro yeinobhururuka saw cutter inomhanyisa kuti ienderane nekumhanya kwematanho ekufamba, iri zvakare kumhanya kwemuchina wekugadzira roll. Izvi zvinogonesa kucheka pasina kumisa maitiro ekugadzira. Iyi yakanyanya kunyatsoita yekucheka mhinduro yakakwana kune yakakwirira-kumhanya mashandiro uye inogadzira marara mashoma.

Munguva yekucheka, simba repneumatic rinofambisa saha blade base rakananga kune strut chiteshi, nepo hydraulic simba kubva ku hydraulic station inotyaira kutenderera kwesaha blade.

Hydraulic Station

Iyo hydraulic station inopa simba rinodiwa kumidziyo senge hydraulic decoiler uye hydraulic cutter uye yakashongedzerwa nemafeni ekutonhodza kuti ive nechokwadi chekubvisa kupisa kunoshanda. Mumamiriro ekunze anopisa, tinokurudzira kuwedzera hydraulic reservoir kuti ivandudze kupisa uye kuwedzera huwandu hwemvura inowanikwa pakutonhodza. Aya matanho anobatsira kuchengetedza yakagadzikana tembiricha yekushanda panguva yekushandiswa kwenguva refu, nekudaro kuve nechokwadi chekuvimbika uye kugona kweiyo roll inogadzira mutsara wekugadzira.

PLC Kudzora Kabati uye Encoder

Encoders inoita basa rakakosha mukuunza mhinduro pane chinzvimbo, kumhanya, uye kuwiriranisa. Ivo vanoshandura kureba kwakayerwa kwesimbi coil kuita masaini emagetsi, ayo anobva atumirwa kuPLC control cabinet. Vashandisi vanoshandisa ratidziro yekabati kuti vagadzirise maparameter akadai sekukurumidza kugadzirwa, kubuda pairi kutenderera, uye kureba kwekucheka. Nekuda kwezviyero chaizvo uye mhinduro kubva kune encoder, muchina wekucheka unogona kuwana kucheka chaiko mukati me ± 1mm.

Flying hydraulic cutting VS Flying saw cut

Kucheka Blade: Dimendi yega yega yeinobhururuka hydraulic cutter inoda yakaparadzana yakamira yekucheka blade. Nekudaro, kucheka kwemasaha hakudzivirirwe nehukuru hwematanho e strut.

Kupfeka uye Kubvarura: Mashizha ekuona anowanzo kurumidza kupfeka zvichienzaniswa nehydraulic cutting blades uye inoda kudzokororwa kakawanda.

Ruzha: Kucheka kwemasaw kunowanzoita ruzha kupfuura hydraulic cut, izvo zvingada mamwe matanho ekudzivirira ruzha munzvimbo yekugadzira.

Marara: A hydraulic cutter, kunyangwe kana yakarimwa zvakafanira, kazhinji inokonzeresa tsvina isingadzivisike ye8-10mm pakuchekwa. Ukuwo, mucheki wemasaha anobudisa tsvina inenge zero.

Maintenance: Saw blades inoda inotonhorera sisitimu yekudzora kupisa kunobva mukukwesha, kuve nechokwadi chekucheka kunoramba kuripo uye kwakanaka. Kusiyana neizvi, hydraulic cutting inochengetedza tembiricha inowirirana.

Material Limitation: Simbi isina simbi ine goho rakakwirira kupfuura rakajairwa kabhoni simbi. Paunenge uchishanda nesimbi isina tsvina, kucheka kwesaha chete kwakakodzera kugadzirisa zvinhu.

1. Decoiler

2. Kudyisa

3.Kubaya

4. Roll forming stands

5. Driving system

6. Kucheka hurongwa

Vamwe

Out table