SQUARE TUBE ROLL KUGADZIRA MACHINE

Mutsetse wekugadzira uyu wakarongedzerwa kugadzira masikweya machubhu ane ukobvu hwe2mm, uye zviyero kubva pa50-100mm muhupamhi uye 100-200mm pakureba.

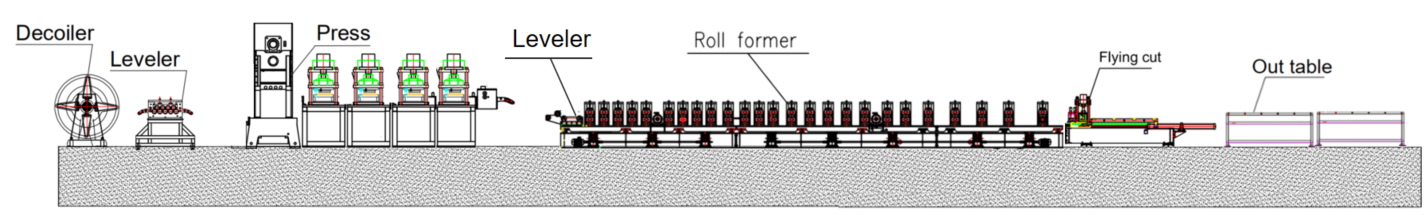

Mutsetse wekugadzira unosanganisira akati wandei akakosha maitiro: decoiling, pre-punch leveling, punching, post-punch leveling, roll-forming, laser welding, kuburitsa fume, uye kucheka.

Inoratidzira yakazara yekuseta uye yepamberi otomatiki, iyi tambo yekugadzira inopa yepamusoro imwe nzira kune yakajairwa welding chubhu michina, kunyanya kune yakaderera mavhoriyamu ekugadzira.

CHAIKO MHOSVA-MAIN TECHNICAL PARAMETERS

Inoyerera chati: Hydraulic decoiler ine mota yekurodha--Leveler--Servo feeder--Punch press--Hydraulic punch--Limiter--Guiding-Leveler--Roll former--Laser weld--Flying saw cut--Out table

CHAIKO MHOSVA-MAIN TECHNICAL PARAMETERS

· Inogadziriswa mutsara kumhanya: 5-6m/min nelaser welding

· Zvishandiso zvinoenderana: Simbi inopisa, simbi inotonhora, simbi nhema

· Ukobvu hwezvinhu: 2mm

· Roll yekugadzira muchina: Kanda simbi chimiro chine mubatanidzwa wepasirese

· Dhiraivha system: Gearbox-inotyairwa sisitimu ine universal joint cardan shaft

· Cutting system: Flying saw cut, ine roll yaimbove ichienderera mberi kushanda panguva yekucheka

· PLC kutonga: Siemens system

CHAIYO MHOSVA-MACHINERY

1.Hydraulic decoiler*1

2.Standalone Leveler*1

3.Punch press*1

4.Hydraulic punch machine*1

5.Servo feeder*1

6.Integrated Leveler*1

7.Roll kugadzira muchina*1

8.Laser welding muchina*1

9.Welding Fume Purifier*1

10.Flying saw cutting machine*1

11.Kunze tafura*2

12.PLC control cabinet*2

13.Hydraulic station*3

14.Spare parts box(Mahara)*1

CHAIKO MHOSVA-TSANANGURO

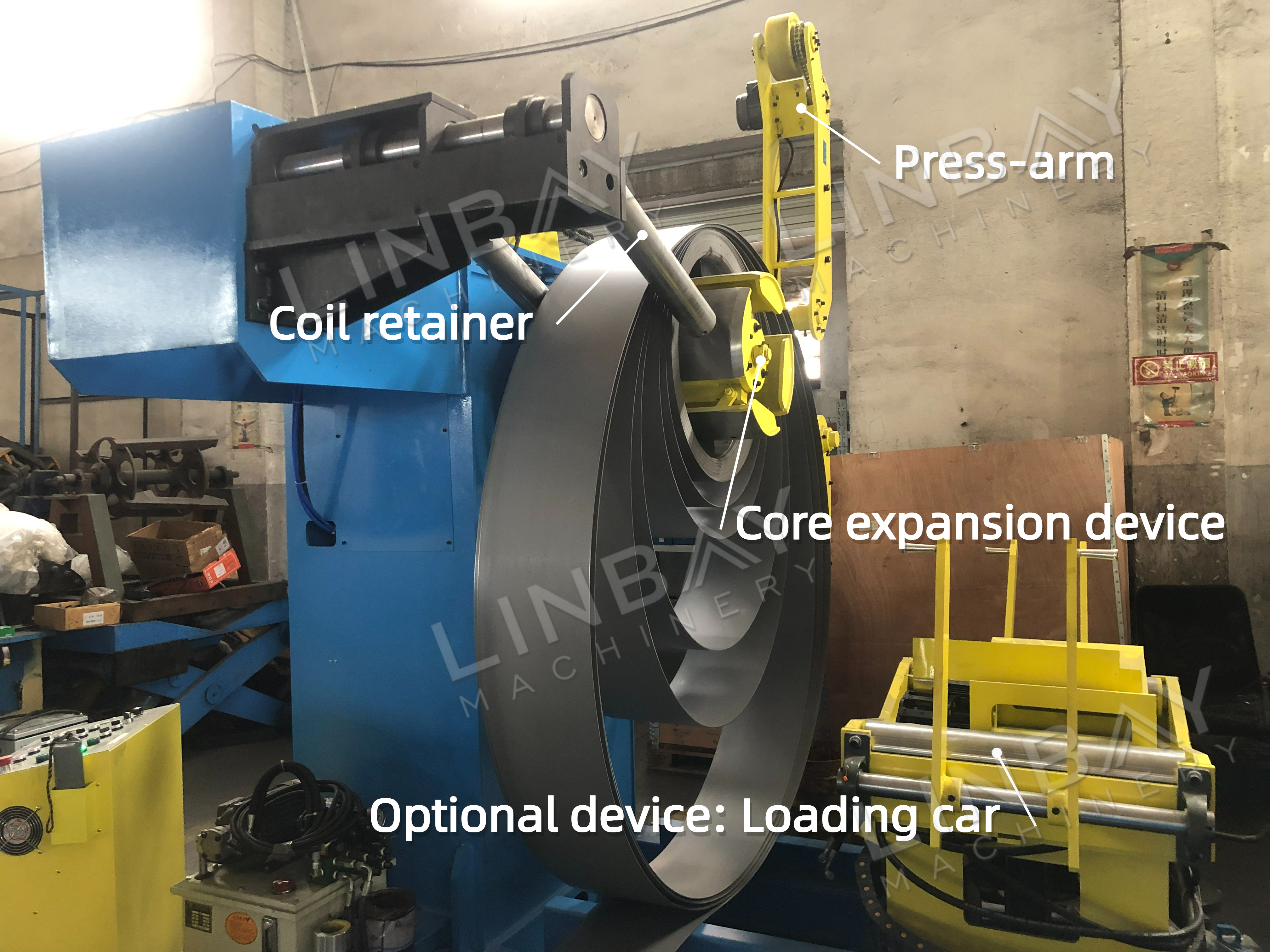

Hydraulic decoiler

•Basa: Iyo yakasimba furemu yakavakirwa kutsigira simbi coil kurodha. Iyo hydraulic decoiler inowedzera kushanda uye kuchengetedzeka mukudyisa simbi coils mumutsara wekugadzira.

•Core Kuwedzera Chishandiso: Iyo hydraulic mandrel kana arbor inogadziridza kuti ikwane simbi coils ine mukati dhayamita ye490-510mm, ichiwedzera uye chibvumirano kuti ibatisise coil uye ive nechokwadi chakatsetseka decoiling.

•Press-ruoko: The hydraulic press arm inochengetedza coil yesimbi, ichidzivirira kungoerekana yasununguka nekuda kwekunetseka kwemukati uye kuchengetedza vashandi kubva kune vangangokuvara.

•Coil Retainer: Iyo dhizaini inoita kuti coil irambe yakachengeteka munzvimbo ichibvumira kuisirwa nyore uye kubviswa.

•Kudzora System: Iyo sisitimu ine PLC uye control panel, iyo inosanganisira bhatani rekumisa emergency kuti riwedzere kuchengetedzwa.

Optional Device: Kutakura Mota

•Inoshanda Coil Replacement: Inobatsira mukuchinja simbi coils zvakachengeteka uye zvinobudirira, kuderedza mari yebasa.

•Hydraulic Alignment: Ipuratifomu inogona kugadziriswa hydraulically kumusoro uye pasi kuti ienderane nemandrel. Pamusoro pezvo, mota inotakura, iyo yakasungirirwa mavhiri, inogona kufamba nemagetsi panjanji.

•Safety Design: Iyo concave dhizaini inobata zvakasimba coil yesimbi, ichidzivirira chero kutsvedza.

Optional muchina: Shearer Butt Welder

· Inobatanidza macoil ekupedzisira uye matsva, kuderedza nguva yekudyisa uye matanho ekugadzirisa emakoiri matsva.

• Inoderedza mari yevashandi uye kutambisa zvinhu.

· Inova nechokwadi chekuveura kwakatsetseka, kusina-burr kuitira kurongeka chaiko uye welding.

· Inoratidzira otomatiki TIG welding yekuenderana uye yakasimba welds.

· Inosanganisira magirazi ekuchengetedza patafura yewelding kuchengetedza maziso evashandi.

· Kudzora kwetsoka kunoita kuti kusungirira kwecoil kuve nyore.

· Customizable kune akasiyana coil hupamhi uye inogona kubatanidzwa nyore nyore muakasiyana mitsara yekugadzira mukati mehupamhi hwayo.

Standalone Leveler

· Inoderedza kushushikana uye kusakwana kwepamusoro mumakoiri esimbi kuburikidza nepurasitiki deformation, kudzivirira kukanganisa kwejometri panguva yekugadzira.

Kudzika kwakakosha kumakoiri akakora kudarika 1.5mm anoda kubaiwa.

· Kusiyana neakasanganiswa levelers akasanganiswa ne decoilers kana roll yekugadzira michina, standalone levelers anoshanda nekumhanya kwakanyanya.

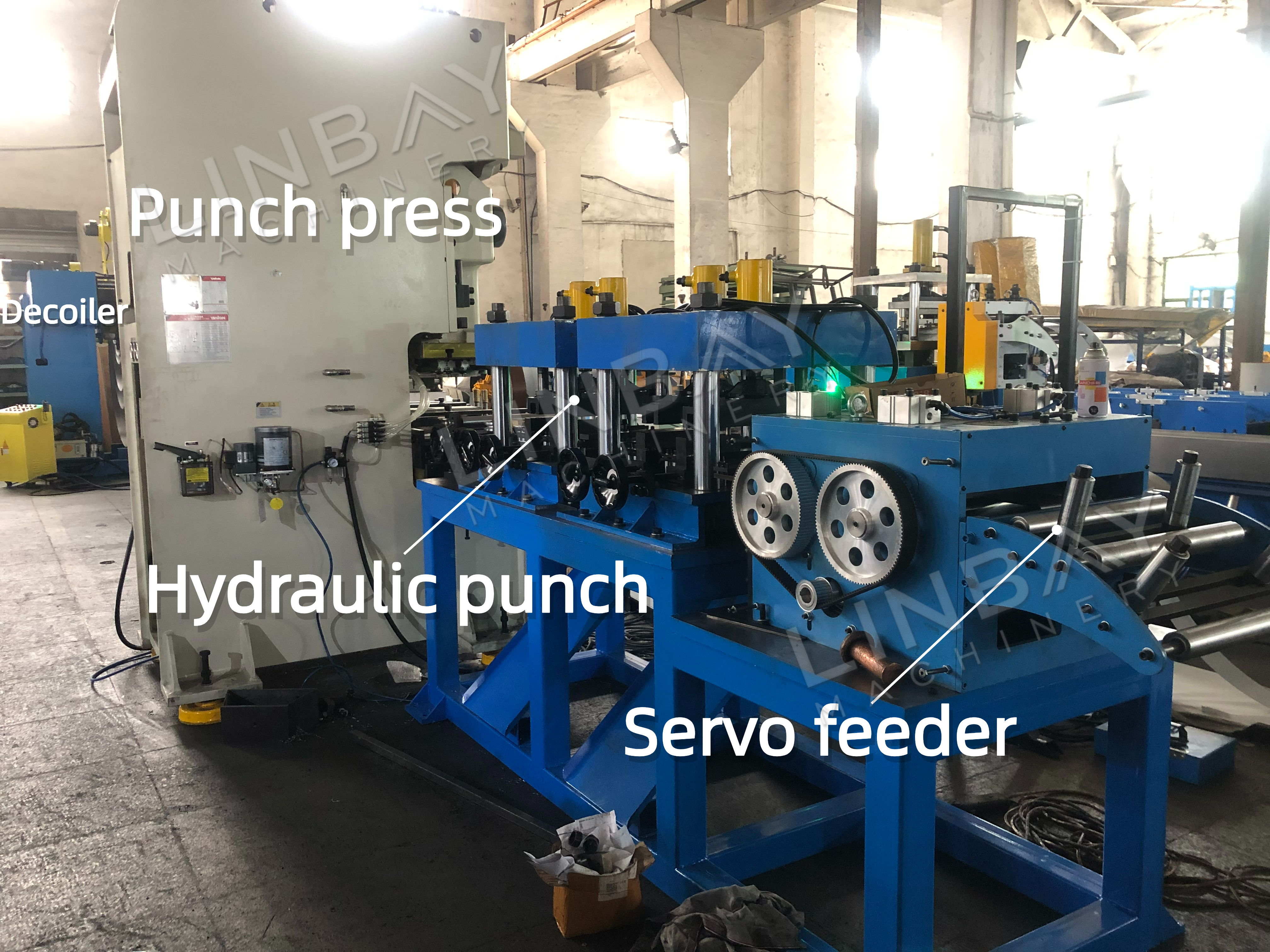

Kurova Chikamu

• Mumutsara wekugadzira uyu, tinoshandisa musanganiswa we punch press uye hydraulic punch yekubaya buri. Chikwata chedu cheinjiniya chakagadzira nzira yakakwana yekubata mapatani egomba akaomarara, kuenzanisa mashandiro uye mutengo nekubatanidza zvakanakira ese ari maviri muchina wekubaya.

Punch Press

· Kukurumidza kushanda.

· Hurukuro hwepamusoro mukuparadzana kwegomba panguva yekubaya.

· Ideal for fixed gomba mapatani.

Hydraulic Punch

• Inopa kuchinjika kukuru kune akasiyana maburi mapatani. Iyo hydraulic punch inogona kuchinjika kune akasiyana gomba maumbirwo, kugadzirisa iyo punching frequency zvinoenderana uye nekusarudza kubaya maumbirwo akasiyana nega rega rega.

Servo Feeder

Iyo yekudyisa, inotyairwa ne servo mota, inonyatso kudzora kudyiswa kwesimbi coils mu punch press kana wega hydraulic punch muchina. Nenguva dzekupindura nekukurumidza uye kunonoka kwekutanga-kumisa kunonoka, servo motors inova nechokwadi chehurefu hwekudya uye kupindirana kwemagomba, kudzikisa zvakanyanya tsvina kubva kune zvibhakera zvisina kurongeka. Iyi sisitimu zvakare inoshanda nesimba, kudhirowa simba chete panguva yekushanda, uye kuchengetedza simba panguva yekusaita basa. Iyo yekudyisa inorongeka zvizere, ichibvumira kukurumidza kugadzirisa munhanho chinhambwe uye punching kumhanya, kucheka panguva yekuseta kana uchichinja punch molds. Pamusoro pezvo, iyo yemukati pneumatic clamping mechanic inodzivirira iyo simbi coil pamusoro kubva kune chero kukuvara kunogona kuitika.

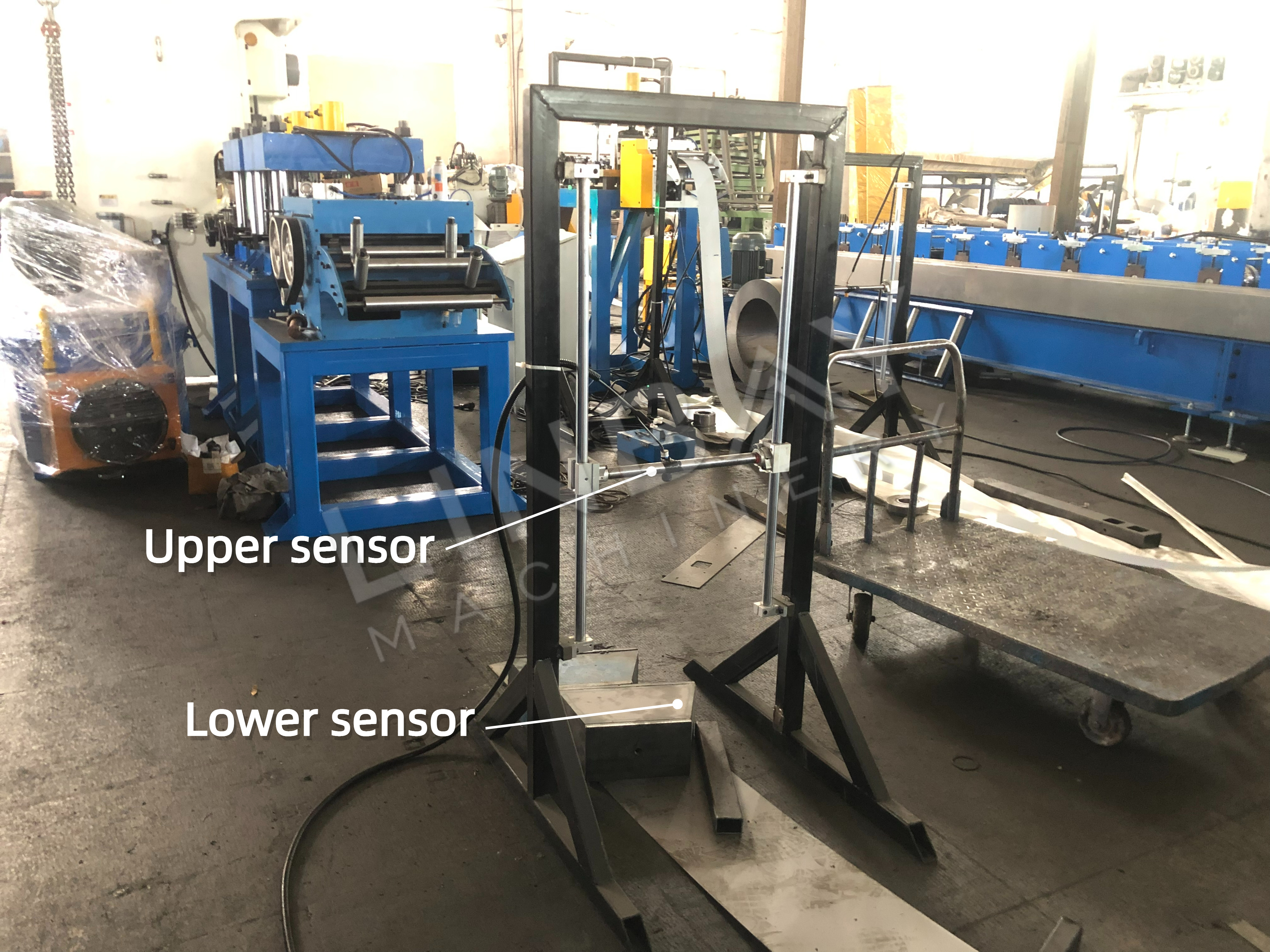

Limiter

Inogadzirisa kumhanya kwekugadzira kuti uwedzere kushanda zvakanaka uye kuchengetedza kushanda kwakachengeteka kweese ari maviri simbi coil uye muchina. Kana iyo coil ikasangana neiyo yepasi sensor, zvinoreva kuti kusunungura, kuyera, uye kurovera maitiro pamberi peiyo limiter ari kushanda nekukurumidza kupfuura anotevera kuumba, welding, uye kucheka matanho. Aya maitiro ekutanga anofanirwa kumbomira kuenzanisa kuyerera kwekugadzira; kana zvisina kudaro, coil buildup inogona kuitika, ichivharidzira kupinda kwayo mumushini wekugadzira uye zvinogona kukonzera deformation. Sezvineiwo, kana iyo coil inobata iyo yepamusoro sensor, inoratidza kuti nhanho dzekupedzisira dziri kufamba nekukurumidza kupfuura dzekutanga, zvinoda kumbomira mumatanho mushure meiyo limiter. Kutadza kuita izvi kunogona kukonzera kuti coil idhonzwe mumuchina wekugadzira roll nekukasira, zvichiisa njodzi yekukuvadzwa pamushini wekubaya uye kugadzira rollers. Chero kumbomira kunokonzeresa chiziviso pane inoenderana PLC kabati kuratidza, zvichibvumira vashandi kuti vatangezve mashandiro nekubvuma kukurumidza.

Kutungamira

Chinangwa chikuru: Inovimbisa kuti coil yesimbi yakanyatsoenderana nepakati yemuchina, kudzivirira nyaya senge kumonyoroka, kukotama, maburrs, uye kusarongeka kwechigadzirwa chakapedzwa. Guiding rollers akaiswa zvine hungwaru panzvimbo yekupinda uye mukati memushini wekugadzira. Izvo zvakakosha kuti utarise aya madhiraivha nguva nenguva, kunyanya mushure mekutakura kana kushandisa kwenguva refu yemuchina wekugadzira roll. Isati yatumira, timu yeLinbay inoyera hupamhi hwekutungamira uye inosanganisira iyi ruzivo mubhuku remushandisi, ichibvumira vatengi kuyera muchina pakutumira.

Sekondari Leveler (Set pachigadziko chimwechete chine roll yekugadzira muchina)

Iyo coil yakatsetseka inovimbisa yepamusoro seam alignment post-forming, iyo inobatsira zvakanyanya mukuita welding. Sekondari leveling inoshanda kuenderera mberi nekuvandudza kunaka kwekuyera uye kuderedza kushushikana pamapoinzi. Sechimwe chiyero chekuwedzera, kuisa iyi leveler pachigadziko chemuchina wekugadzira inopa inodhura-inoshanda uye yakakodzera maitiro.

Roll Kugadzira Machine

· Kugadzirwa kwakasiyana-siyana: Mutsara uyu unokwanisa kugadzira masikweya machubhu ane zviyero kubva pa50-100mm muhupamhi uye 100-200mm pakureba. (Linbay inogona kupawo kugadzirisa kune mamwe saizi masaizi.)

· Automated Size Shanduko: Nekumisikidza uye nekusimbisa saizi yaidiwa paPLC skrini, zviteshi zvekugadzira zvotozvichinja zvichitevedza njanji kuenda kunzvimbo chaidzo, kugadzirisa nzvimbo yekugadzira zvinoenderana. Iyi otomatiki inosimudzira kurongeka uye nyore, kuderedza kudiwa kwekugadzirisa manyore uye mari yakabatana.

· Lateral Movement Detection: Iyo encoder inonyatso kuteedzera mafambiro ekupedzisira ezviteshi zvekugadzira uye ipapo inodzosera iyi data kuPLC, ichichengetedza zvikanganiso zvekufamba mukati me1mm kushivirira.

· Safety Limit Sensors: Maviri ekuchengetedza ekudzivirira masensa akaiswa pamativi ekunze enjanji. Iyo yemukati sensor inodzivirira yekugadzira zviteshi kuti isaswedere pedyo zvakanyanya, kudzivirira kudhumhana, nepo yekunze sensor ichiona kuti haifambire kure kure.

· Yakasimba Cast-iron Frame: Inoratidzira yakazvimiririra yakatwasuka furemu yakagadzirwa kubva kusimbi yakakandwa, iyi yakasimba chimiro chakanakira yepamusoro-chaiyo kugadzirwa zvinodiwa.

· Yakasimba Drive System: Iyo giya bhokisi uye yepasirese yakabatana inoburitsa simba rakasimba, ichigonesa kushanda kwakatsetseka kana uchifambira mberi makoiri akakora kupfuura 2mm kana pakugadzira kumhanya kunodarika 20m/min.

· Durable Rollers: Chrome-yakaputirwa uye inopisa-yakagadziriswa, aya rollers anodzivisa ngura uye kuora, kuchengetedza hupenyu hurefu.

· Main Motor: Iyo yakajairwa gadziriso ndeye 380V, 50Hz, 3-chikamu, ine sarudzo dzekugadzirisa dziripo.

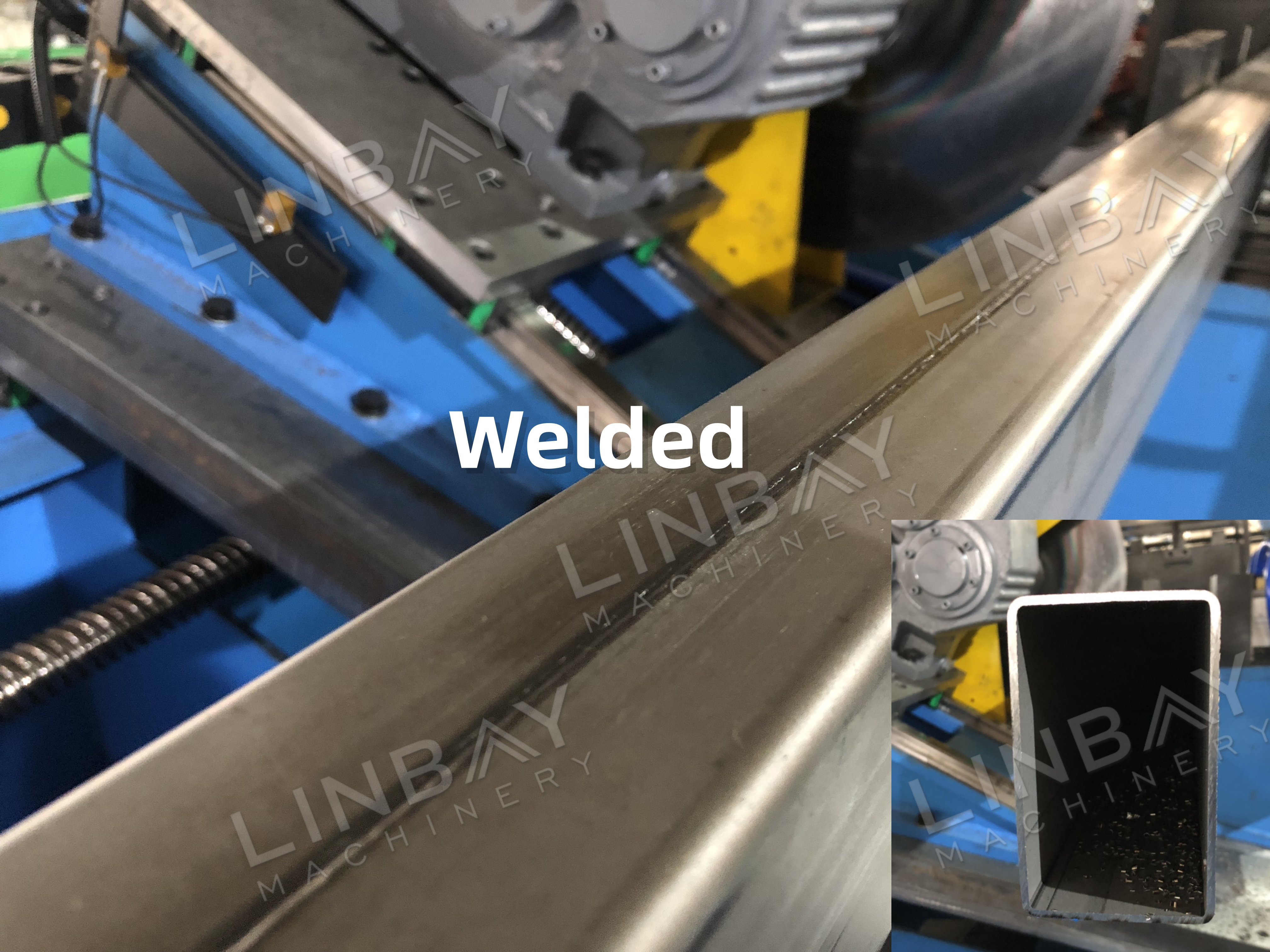

Laser Weld

· Hunhu Hwakagadziridzwa uye Precision: Inopa kurongeka kwepamusoro uye kubatana kwakasimba.

· Yakatsvinda uye Yakakwenenzverwa Joint: Inovimbisa kuchena, kupera kwakatsetseka pakubatanidzwa.

Welding Fume Purifier

• Kudzora Kunhuhwirira uye Kudzora: Inobata uye inobvisa kunhuhwirira nehutsi hunogadzirwa panguva yewelding, kuve nechokwadi chekuchengetedza fekitori nharaunda uye kuchengetedza hutano hwevashandi.

Flying Saw Cut

· Flying Cut: Iyo yekucheka unit inopindirana nekumhanya kwemuchina wekugadzira panguva yekushanda, inowedzera kushanda kwekugadzira uye kubuda.

· Precision Cutting: Iine servo mota uye inofamba controller, iyo yekucheka unit inochengetedza kurongeka kwe ± 1mm.

· Sawing Method: Inopa machekwa chaiwo pasina kukanganisa mipendero yemaprofiles akavharwa.

· Kubudirira Kwezvinhu: Kuchekwa kwega kwega kunoburitsa tsvina shoma, kuderedza mari yezvinhu.

·Flexible Operation: Kusiyana nedzimwe nzira dzekucheka dzinoda mablades chaiwo ehukuru hwakasiyana, kucheka kwemasaha kunochinjika, kunopa mari yekuchengetedza pamashizha.

1. Decoiler

2. Kudyisa

3.Kubaya

4. Roll forming stands

5. Driving system

6. Kucheka hurongwa

Vamwe

Kunze tafura