Which has a positive and progressive attitude to customer’s desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of Special Price for China Scaffolding Plank Walking Board Galvanized Steel Plank Machine, We sincerely welcome overseas consumers to consult for your long-term cooperation as well as the mutual advancement.We strongly think that we will do superior and far better.

Which has a positive and progressive attitude to customer’s desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of China Scaffolding Machine, construction platform machine, construction platform making machine, iron scaffold plank machine, iron scaffold plank roll former, scaffold board rolling machine, scaffold foot pedal machine, Scaffold plank roll forming machine, scaffold slab roll forming machine, scaffolding foot plate machine, scaffolding foot plate making machine, scaffolding plate making machine, Scaffolding Platform machine, Scaffolding Platform making machine, Scaffolding Platform roll former, scaffolding walk plank machine, Walk Board Machine, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Description

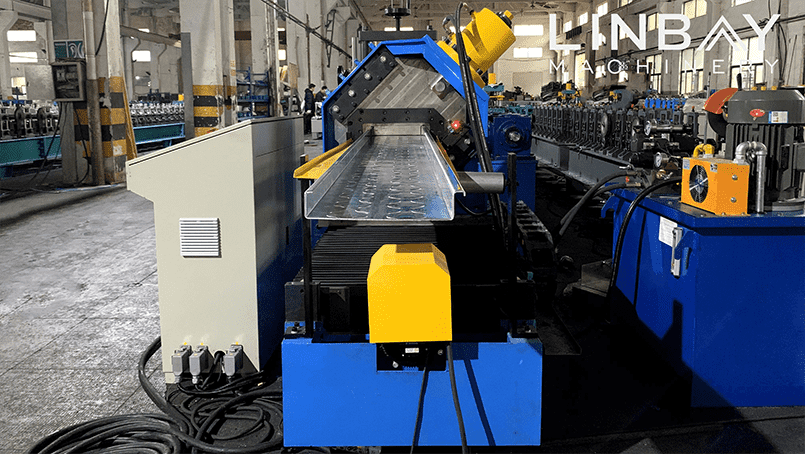

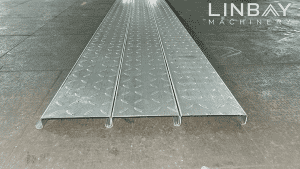

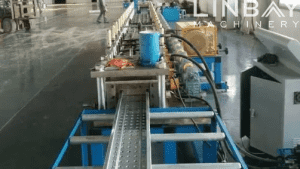

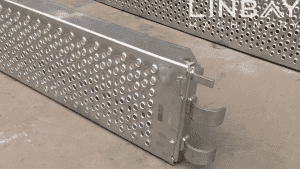

Scaffold plank roll forming machine can make scaffold plank. We adopt servo feeder to make sure the holes are in high precision. We use punching press to make line speed faster and we use hydraulic post cutting to make sure the profile perfect.

The thickness of raw material is around 1-2mm.

Application

Technical Specifications

Flaw Chart

Manual decoiler–feeding–hydraulic punching station–forming machine–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

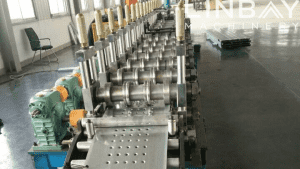

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table