Perfil

Beam ea mohato e phetha karolo ea bohlokoa holitsamaiso tse boima tsa ho roka liphalete, ka ho toba ho susumetsa matla le matla a ho jara moroalo oa mohaho oohle.

Hangata bahlahisi ba sebelisa mechini e etsang roll ka1.5-2mm tšepe e chesang kapa e batangho hlahisa maballo a mohato. Ho ntlafatsa bophelo ba bona le ho thibela deformation e bakoang ke tsitsipano ea tšepe, welding e sebelisoa manonyeletsong a tšepe. Mekhoa e 'meli e tloaelehileng ea welding e sebelisoang indastering keMIG welder (joaloka tabeng ena) le laser full welder.

Ka bobeli MIG welder le laser full welder li kenya letsoho ho matlafatsang botšepehi ba sebopeho. Leha ho le joalo, ka lebaka la ho koaheloa ka botlalo ha manonyeletso a ho cheselletsa ka botlalo, katleho ea ona e feta ea MIG ea ho cheselletsa. Bareki ba ka khetha mokhoa oa ho tjheseletsa ho latela tekanyetso ea bona le litlhoko tsa ho kenya rack.

Taba ea 'nete-Mekhabiso e ka Sehloohong ea Techinical

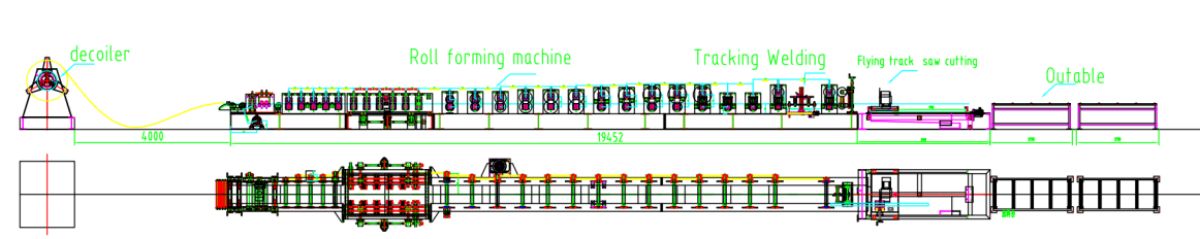

Chate e phallang

Manual decoiler--Guiding--Leveler--Roll forming machine--Flying welder--Flying saw cut--Out table

Mekhahlelo e ka Sehloohong ea Techinical

1.Lebelo la Line: 4-5 m / min, e fetohang

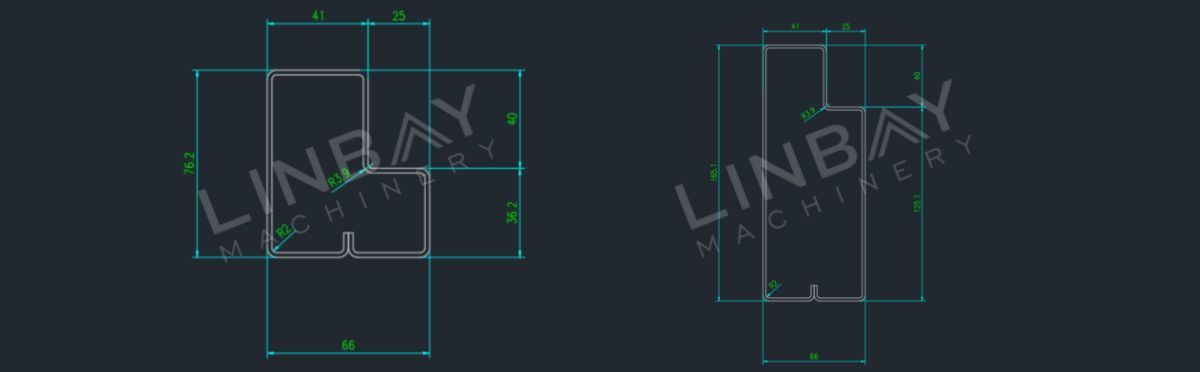

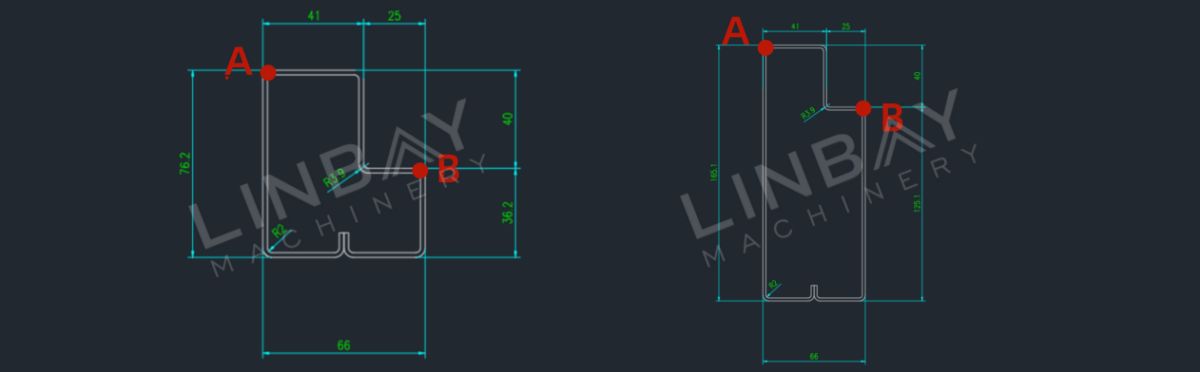

2.Profiles: Mefuta e mengata-bophara bo lekanang ba 66mm, le bophahamo bo fapaneng ba 76.2-165.1mm

3.Material botenya: 1.9mm (tabeng ena)

4.Lisebelisoa tse loketseng: Tšepe e chesang e kolobisitsoeng, tšepe e pholileng e batang, tšepe e entsoeng ka masenke

Mochini oa ho etsa 5.Roll: Sebopeho sa Cast-iron le sistimi ea ho khanna ketane.

6. Che. Ea ho theha seteishene: 26

7.Sistimi ea welding: 2 * litoche tsa welding, roll ea pele ha e emise ha ho chesoa.

8.Cutting system: Saw cutting, rollformer ha e emise ha e khaola.

9.Ho fetola boholo: Ka tsela e iketsang.

10.PLC cabinet: Siemens tsamaiso.

Taba ea 'nete-Tlhaloso

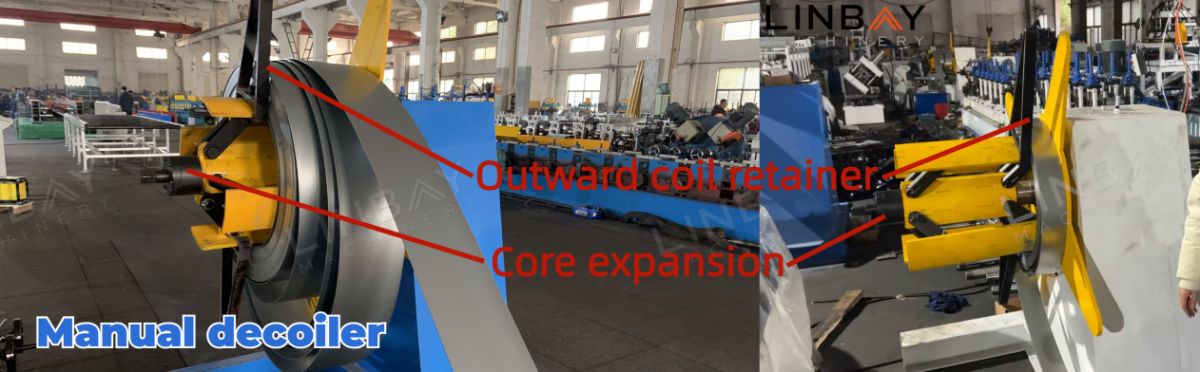

Manual Decoiler

The decoiler manual e na le asesebelisoa sa brakee etselitsoe ho lokisa tsitsipano ea mantlha ea katoloso ka har'a mefuta ea φ490-510 mm, ho netefatsa ts'ebetso e bonolo ea ho koala. Ha ho nahanoa ka ts'ebeliso ea khoele ea tšepe ea 1.9mm, ho na le kotsi ea hore e bulehe ka tšohanyetso nakong ea ha e khoasolla.Ho sebetsana le polokeho enaho tšoenyeha, letsoho la khatiso le kenngoa ho boloka tšepe ea tšepe ka mokhoa o sireletsehileng, ha li-blades tsa tšepe tse sireletsang li kenngoa ho thibela ho thella ha li-coil. Moralo ona ha o fane feela ka tharollo e bolokang chelete e ngata empa hape o etelletsa pele polokeho ts'ebetsong ea ho khoasolla.

The decoiler manual e na leha ho matla. Bakeng sa litlhoko tse phahameng tsa tlhahiso ea tlhahiso, re fana ka khethohydraulic decoilere tsamaisoang ke seteishene sa hydraulic.

Pontsho ya Tataiso & Digital

Lirolara tse tataisang li bapala karolo ea bohlokoa ho boloka tumellano lipakeng tsa coil ea tšepe le mechini, ka hona, li thibela ho khopama ha sethala le ho kenya letsoho ts'ebetsong ea ho theha moqolo.thibela deformation rebound ea tšepe. Ho otlolohaea Beam ea mohato ke ea bohlokoa bakeng sa boleng ba sehlahisoa mme e ama ts'ebetso e jereng mojaro oa sistimi eohle ea racking. Lirolara tse tataisang li behiloe ka mokhoa o hlophisehileng eseng feela qalong ea mochini o etsang moqolo empa hapelintlheng tse fapaneng ho latela mola oohle oa ho etsa moqolo, ho etsa bonnete ba ho lumellana ho nepahetseng ho pholletsa le ts'ebetso ea tlhahiso.

Lisebelisoa tsa ponts'o tsa dijithale lia thusarekoto e loketsengya boemo bo nepahetseng ba dirolara tse tataisang. Lelitekanyo tsa sebakaho tloha ho e 'ngoe le e' ngoe e tataisang rolara ho ea ka lehlakoreng le letšehali le ka ho le letona la mochine oa ho etsa moqolo li ngotsoe bukeng ea litaelo, e leng ho lumellang hore ho be le liphetoho tse bonolo tse thehiloeng ho lintlha tsena esita le haeba ho falla hanyenyane ho etsahala nakong ea lipalangoang kapa tlhahiso.

Leveler

Ka mor'a sena, coil ea tšepe e tsoela pele ho leveler. Ka lebaka la botenya ba eona ba 1.9mm, ho bohlokoa hotlosa kobeha efe kapa efe e teng ka har'a coil ea tšepe, ka tsela eo e ntlafatsa ho bata le ho ts'oana ha eona bakeng sa boleng ba sethala sa mohato. E na le lirolara tse 3 tse holimo le tse 4 tse tlase, mochini o tsamaisang maemo o fihlela sepheo sena ka nepo, a netefatsa ho bata le ho tsamaisana ho hotle bakeng sa ts'ebetso e latelang ea ho theha meqolo.

Mochini oa ho etsa Roll

Bohareng ba mohala oohle oa tlhahiso ho na le mochini o etsang roll. E na le taolo e fapaneng ea lebelo e tsamaisoang ke inverter ea (brand ea Japane) Yaskawa, mochine o fana ka lebelo le fapaneng la lebelo ho tloha ho 0 ho ea ho 10m / min, ho netefatsa ho ikamahanya le maemo ho litlhoko tse fapaneng tsa tlhahiso. E na le liteishene tse 26 tsa ho theha, e sebelisasebopeho sa lebota le tsamaiso ea ketane ea ho khanna, e entsoeng ka makhethe ho fana ka ho nepahala le ho sebetsa hantle ha ho etsoa. Ka theknoloji ea eona e tsoetseng pele le moralo o matla, mochini o etsang roll o sebetsa e le lejoe la sekhutlo la boleng le tlhahiso ka har'a mohala oa tlhahiso.

E khona ho hlahisaboholo bo fapaneng, ka bophara ba 66mm le bophahamo ho tloha ho 76.2 ho isa ho 165.1mm, tsamaiso ena e fana ka ho feto-fetoha ha tlhahiso. Kamora ho kenya bophara le bophahamo bo tlase bo lakatsehang ka har'a khabinete ea taolo ea PLC, liteishene tsa ho etsa li ikamahanya le maemo le ho li fetola.lintlha tsa bohlokoa tsa ho theha (lintlha tsa A le B), e bebofatsang liphetoho tsa boholo ka nako ea metsotso e ka bang 10. Liphetoho tsa bophahamo li lumellana le ho fapana ha lintlha tsa bohlokoa tsa ho theha (lintlha tsa A le tsa B), tse nolofalletsang tlhahiso ea maballo a mehato e nang le bophahamo bo fapaneng.

Gcr15, tšepe e nang le carbon e phahameng ea chromium e tsebahalang ka ho thatafala ha eona le ho se mamelle, e sebelisoa bakeng sa thepa ea ho etsa lirolara. Ho eketsa nako e telele, li-roller li kenngoa ka chrome plating. Ntle le moo, li-shafts tse entsoeng ka thepa ea 40Cr li fumana kalafo ea mocheso, li matlafatsa matla le ho netefatsa kaho e matla.

Flying MIG Welder

Ho lelefatsa bophelo ba leballo la mohato le ho thibela karohano ho likhoele tsa tšepe, ho sebelisoa tjheseletsa manonyeletsong a likhoele tsa tšepe ka mokhoa oa matheba. Sekhahla lipakeng tsa letheba ka leng se ka fetoloa ho latela litlhoko tsa bareki. Ho feta moo, litoche tse peli tsa welding li kentsoe ho eketsa lebelo la mohala. Lirumula tsenae ka tsamaea ka nako e le 'ngoe le lebelo la ho etsa moqolo, ho netefatsa ts'ebetso e tsoelang pele ea mochini o etsang roll.

Flying Saw Cutting

Ka mor'a ho etsoa ha moqolo, mohato oa mohato o tsoela pele ho ea mochine oa ho itšeha, o sebelisa mochine oa ho itšeha ka lebaka la sebopeho se koetsoeng sa sefate sa mohato. Li-blades tse khethehileng tsa saw li tiisa ho nepahala le ho thatafala, ha a ntse asefafatsi se phodilenge sireletsa mahare a sakha, e lelefatsa bophelo ba eona. Le hoja lebelo la ho seha sa saw le lieha ho feta ho kuta ka hydraulic,mosebetsi oa selefouno o kenyelelitsoe ho amahanya le lebelo la tlhahiso ea mochini o etsang roll, ho netefatsa ts'ebetso e sa sitisoeng. Ho feta moo, mochini oa ho itšeha o tiisa litšila tse fokolang nakong ea phetolo ea tšepe ea tšepe le ho itšeha ha profil.

Encoder & PLC

Ka har'a mochini o etsang roll, encoder ea Japane ea Koyo e fetolela bolelele ba coil ka nepo hore e be lets'oao la motlakase, ebe le fetisetsoa khabineteng ea taolo ea PLC. Selaoli sa motsamao, se kentsoeng ka har'a khabinete ea taolo ea motlakase, se netefatsa ho potlakisa ho se nang moeli le ho fokotseha nakong ea motsamao o eang pele le oa morao oa mochini oa ho itšeha, ka hona o fihlela bolelele bo nepahetseng ba ho itšeha. Mokhoa ona oa ho laola ka hloko o tiisa mats'oao a tsitsitseng le a boreleli, ho thibela libalaka hore li se ke tsa peperana le ho netefatsa tlhahiso e tsitsitseng, ea boleng bo holimo. Basebelisi ba ka laola lebelo la tlhahiso habonolo, ba beha litekanyo tsa tlhahiso, bolelele ba ho itšeha, le tse ling ka skrine ea PLC. Ntle le moo, khabinete ea taolo ea PLC e na le ts'ebetso ea polokelo ea memori bakeng sa liparamente tse sebelisoang hangata mme e fana ka ts'ireletso khahlano le moroalo o mongata, potoloho e khuts'oane le tahlehelo ea karolo, ho netefatsa ts'epo ea ts'ebetso le polokeho.

Puo e skrineng sa PLC e ka etsoa ho latela litlhoko tsa bareki.

Seteishene sa Hydraulic

Seteishene sa rona sa hydraulic se na le fan ea motlakase e pholileng ho felisa mocheso hantle, ho netefatsa ts'ebetso ea nako e telele le e ts'epahalang ka litefiso tse tlase tsa ho hloleha.

Tiisetso

Ka mor'a ho romelloa, letsatsi la ho pepa le bontšoa ka lebitso la tšepe, ho fana ka tiiso ea lilemo tse peli bakeng sa mohala oohle oa tlhahiso le tiiso ea lilemo tse hlano bakeng sa li-roller le shafts.

1. Decoiler

2. Ho fepa

3.Ho phunya

4. Litomo tsa ho etsa roll

5. Mokhoa oa ho khanna

6. Mokhoa oa ho khaola

Ba bang

Tafole e kantle

1-300x168.jpg)