PALESO

Li-tubes tse chitja tse awning ke likarolo tsa bohlokoa bakeng sa li-awnings, hangata li hahiloe ka aluminium kapa tšepe e entsoeng ka masenke. Li-diameter tse tloaelehileng li kenyelletsa 60/63/70/78/80/85mm, 'me hangata li fumaneha ka bolelele ba limithara tse 4, 5, 6, kapa 7.

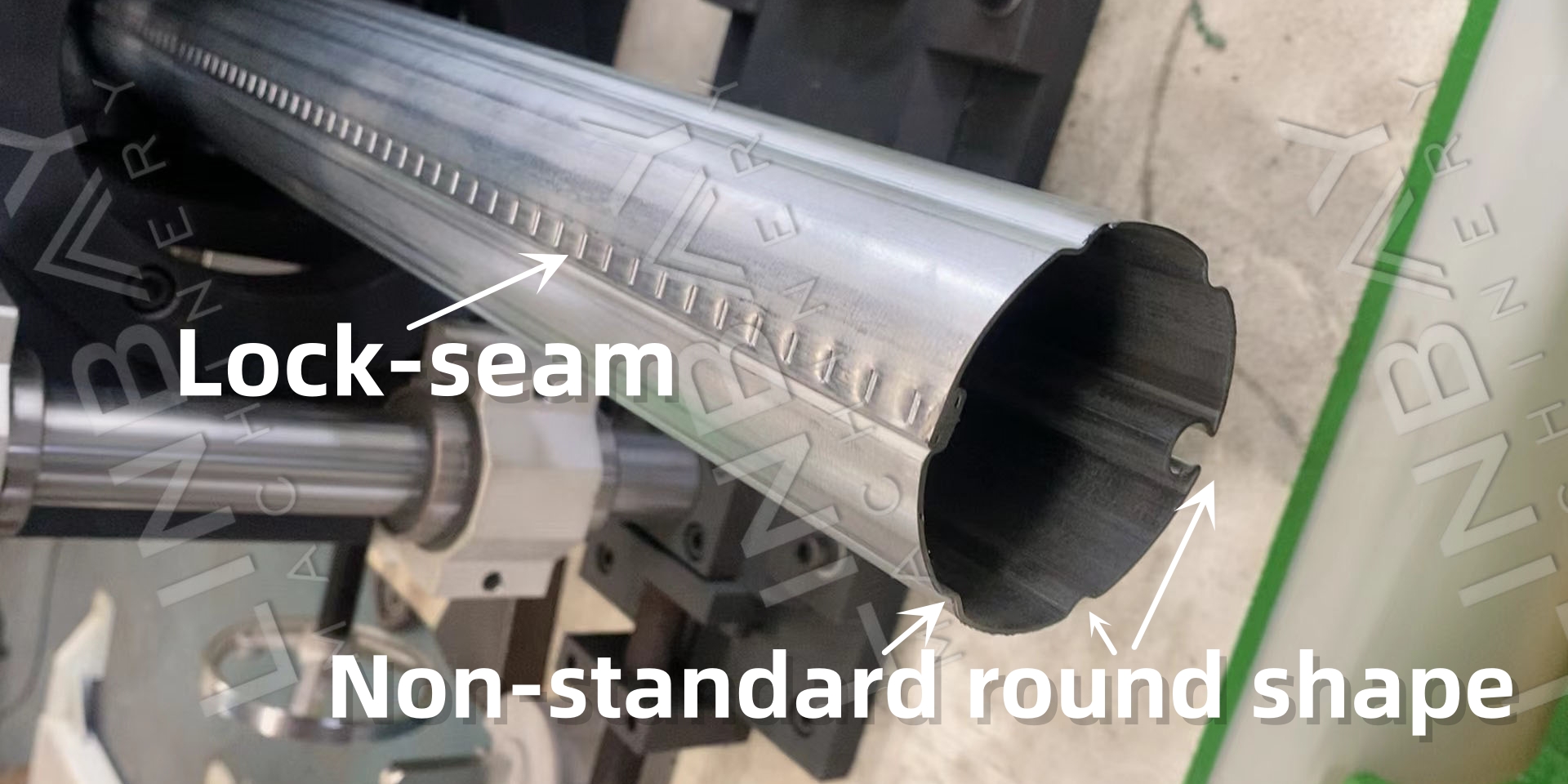

Mokhoa o tloaelehileng oa tlhahiso: Likhoeli tsa tšepe li pota-potiloe ho pota-pota hlobo ea cylindrical ebe lia hatelloa ho etsa tšupu e chitja. Mokhoa ona o fella ka kabo e sa lekaneng ea matla, ts'ebetso e tlase, le mefokolo ho bolelele ba li-tube le bophara bo fokolang. Ho feta moo, ho thata ho etsa li-tubes tse nang le meralo e sa tloaelehang, joalo ka ha ho bonts'itsoe setšoantšong se ka tlase.

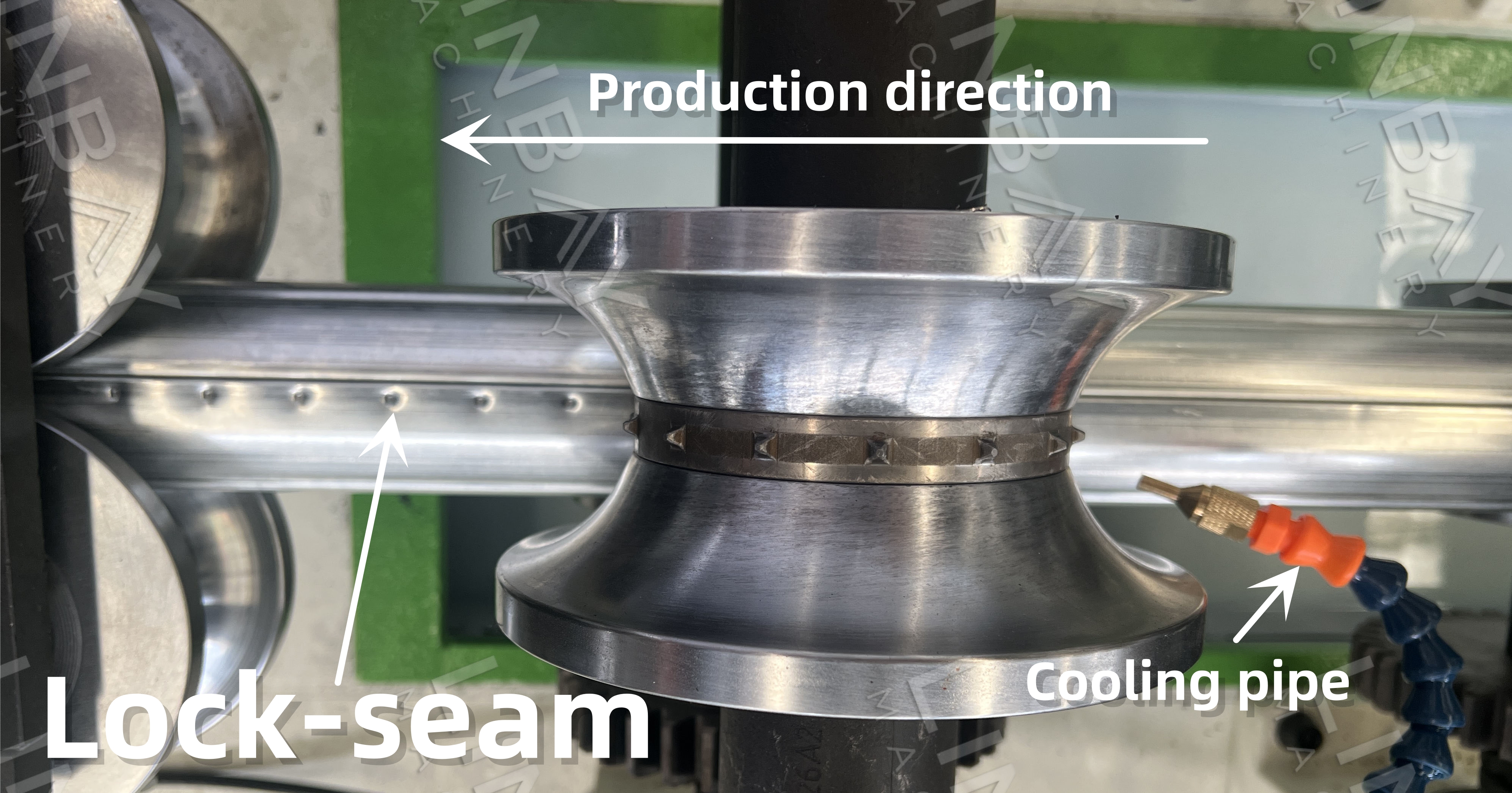

Mokhoa o Mocha: Mochini oa ho Etsa Roll.Mokhoa oa ho etsa moqolo butle-butle o bopa thepa ka rolara e 'ngoe le e 'ngoe, e ntse e e kobeha ho fihlela e fetoha tube e chitja, e notletsoeng. Kabo ena ea matla a tšoanang e fokotsa ho khutla. Likhoele tsa tšepe li ka fepeloa khafetsa ntle le ho hloka ho sehoa pele, 'me bolelele ba li-tube bo ka khaoloa hantle ka nepo ea ± 1mm. Mokhoa ona o nepahetse bakeng sa ho hlahisa li-tubes tse nyane tsa bophara le meralo e tloaelehileng ea moeli. Ke tharollo e sebetsang hantle le ea moruo bakeng sa bareki.

SEBELE-TEKELETSO TSE KHOLO EA LITŠOANTŠISO

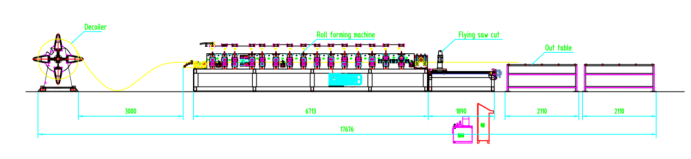

Chate e phallang: Decoiler--Guiding-Roll former--Flying saw cut--Out table

SEBELE-TEKELETSO TSE KHOLO EA LITŠOANTŠISO

1.Lebelo la Line: 0-10m / min, e ka fetoloa

2.Lisebelisoa tse loketseng: Tšepe e entsoeng ka galvanized, aluminium

3.Material botenya: 0.8-1mm

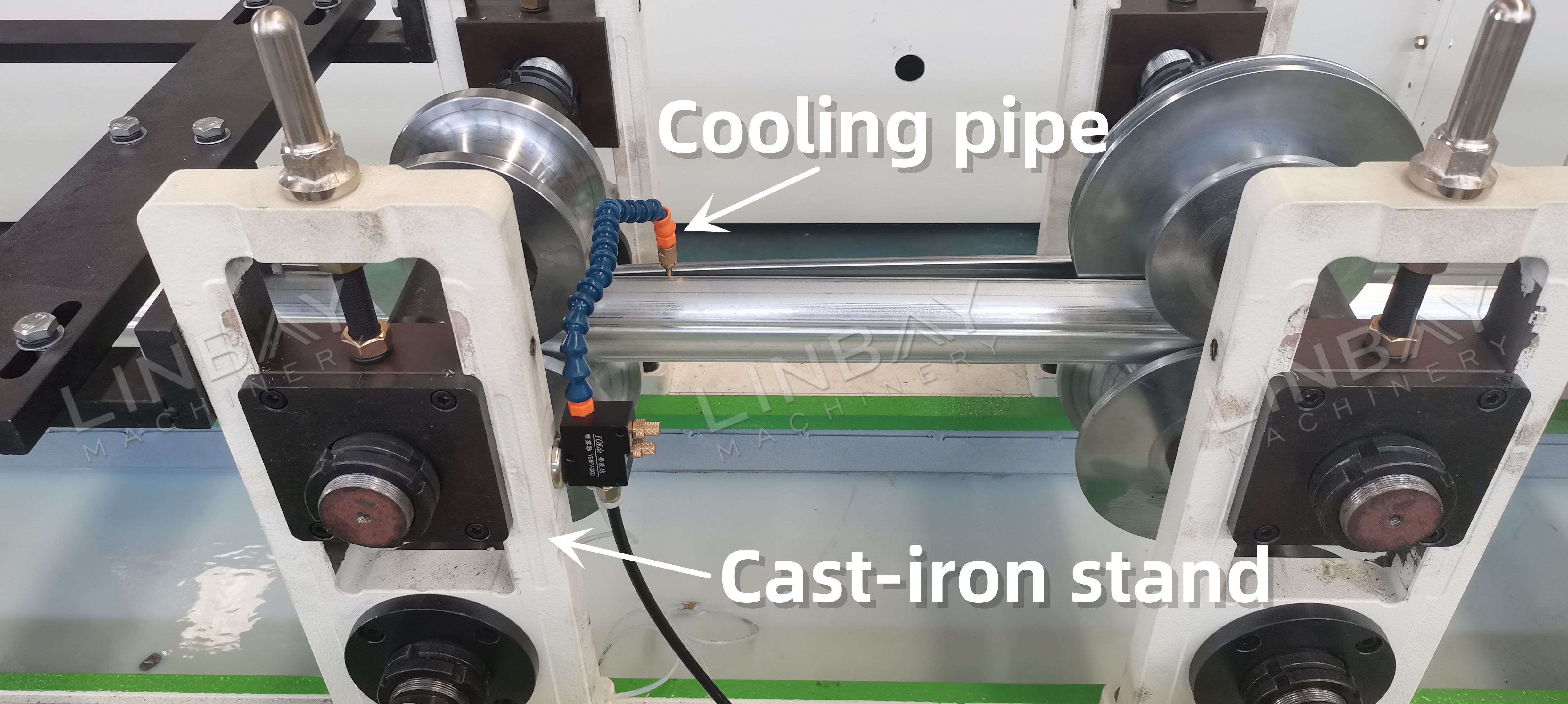

Mochine oa ho etsa 4.Roll: Sebopeho sa Cast-iron

5.Sistimi ea ho khanna: Sistimi ea ho khanna ea Gearbox e nang le mochini o kopaneng oa cardan shaft.

6.Cutting system: Flying saw cut, roll ea pele ha e emise ha e khaola.

7.PLC cabinet: Siemens tsamaiso.

SEBELE-MACHINA

1.Manual Decoiler*1

2.Roll forming machine*1

3.Flying saw mochini o sehang*1 (Ho kenyeletsoa lehare la saw*1)

4.Ka ntle ho tafole*2

5.PLC control cabinet*1

6.Seteishene sa Hydraulic*1

7.Lebokose la li-spare parts(Mahala)*1

TLHALOSO SEBELE

Manual Decoiler

· Frame e tiileng:Foreimi e hahiloe hore e be matla le ho tsitsa, e entsoe ka ho khetheha ho tšehetsa likhoele tsa tšepe ka mokhoa o sireletsehileng.

Katoloso ea Mandrel:Mandrel kapa arbor e ka fetoloa ka letsoho ho atolosa le ho amohela lithapo tsa tšepe tse nang le bophara bo ka hare ho tloha ho 490-510mm. Sena se etsa bonnete ba hore khoele e ts'oaroe ka thata bakeng sa ho qhibiliha hamonate.

· Coil Retainer:Karolo ena e etselitsoe ho thibela khoele ea tšepe hore e se ke ea theoha mandrel. Ho bonolo ho hokela le ho tlosa.

· Likhetho tse teng:Bakeng sa matla a ntlafalitsoeng le boiketsetso, mefuta ea motlakase kapa haeteroliki ea sesebelisoa sa mantlha sa katoloso ea fumaneha. Leha ho le joalo, mofuta oa tataiso o ratoa bakeng sa li-tubes tse chitja tse awning ka lebaka la likhoele tsa tšepe tse tšesaane le tse tšesaane tse amehang.

Tataiso

· Karolo ea mantlha: E boloka tumellano e nepahetseng ea khoele ea tšepe le setsi sa mochini oa mochini, e thibela litaba tse kang ho sotha, ho kobeha le ho etsa li-burr. Ho tsamaisana hantle ho bohlokoa bakeng sa ho netefatsa hore seams tsa li-tubes tse chitja tse sirelelitsoeng li tiile ebile li sireletsehile.

· Multiple Guides Systems: Ha e fumanehe feela sebakeng sa ho fepa empa hape le ho pholletsa le mochine oa ho etsa ho etsa bonnete ba hore tube e lula e otlolohile nakong ea tlhahiso.

· Kemiso ea kamehla: Ho lokisoa khafetsa ha litsamaiso tse tataisang hoa hlokahala, haholo kamora lipalangoang kapa nako e telele ea ts'ebeliso.

· Litokomane tsa Pre-Shipment: Sehlopha sa Linbay se lekanya ka hloko le ho tlaleha bophara ba tataiso pele se romelloa, se fana ka lintlha tsena bukeng ea mosebelisi ho thusa ho lekanya hantle ha moreki a fumana.

Roll Former

· Kaho e Matla: E na le sethala sa tšepe bakeng sa ho tšoarella ho matlafalitsoeng.

· Sistimi e matla ea ho khanna: E na le lebokose la li-gear le motsoako oa bokahohleng o fanang ka matla a matla a ho khanna ho lirolara, ho netefatsa hore ho etsoa li-coil tsa tšepe tse boreleli le tse tsitsitseng.

· Flexible Production: Mochini o le mong oa ho etsa moqolo o amohela likhasete tse fapaneng, e 'ngoe le e' ngoe e etselitsoe li-diameter tse itseng tse chitja. Fetola lik'hasete feela ho hlahisa liphaephe tsa boholo bo sa tšoaneng.

· Tšebeliso ea Litšenyehelo: E fana ka tharollo ea moruo haholoanyane ka ho felisa tlhoko ea mela e arohaneng ea tlhahiso bakeng sa li-diameter tse fapaneng tsa tube.

· Seam Seam: E fana ka tiisetso ea moroko oa senotlolo o tla lula o tiile, o thibela ho hloleha hofe kapa hofe ho ka bang teng.

· Sustainable Cooling System: E sebelisa mochine o pholileng o potolohang ho boloka mocheso oa rolara o le tlase, ho ntlafatsa boleng ba ho bopa le ho lelefatsa bophelo ba rolara.

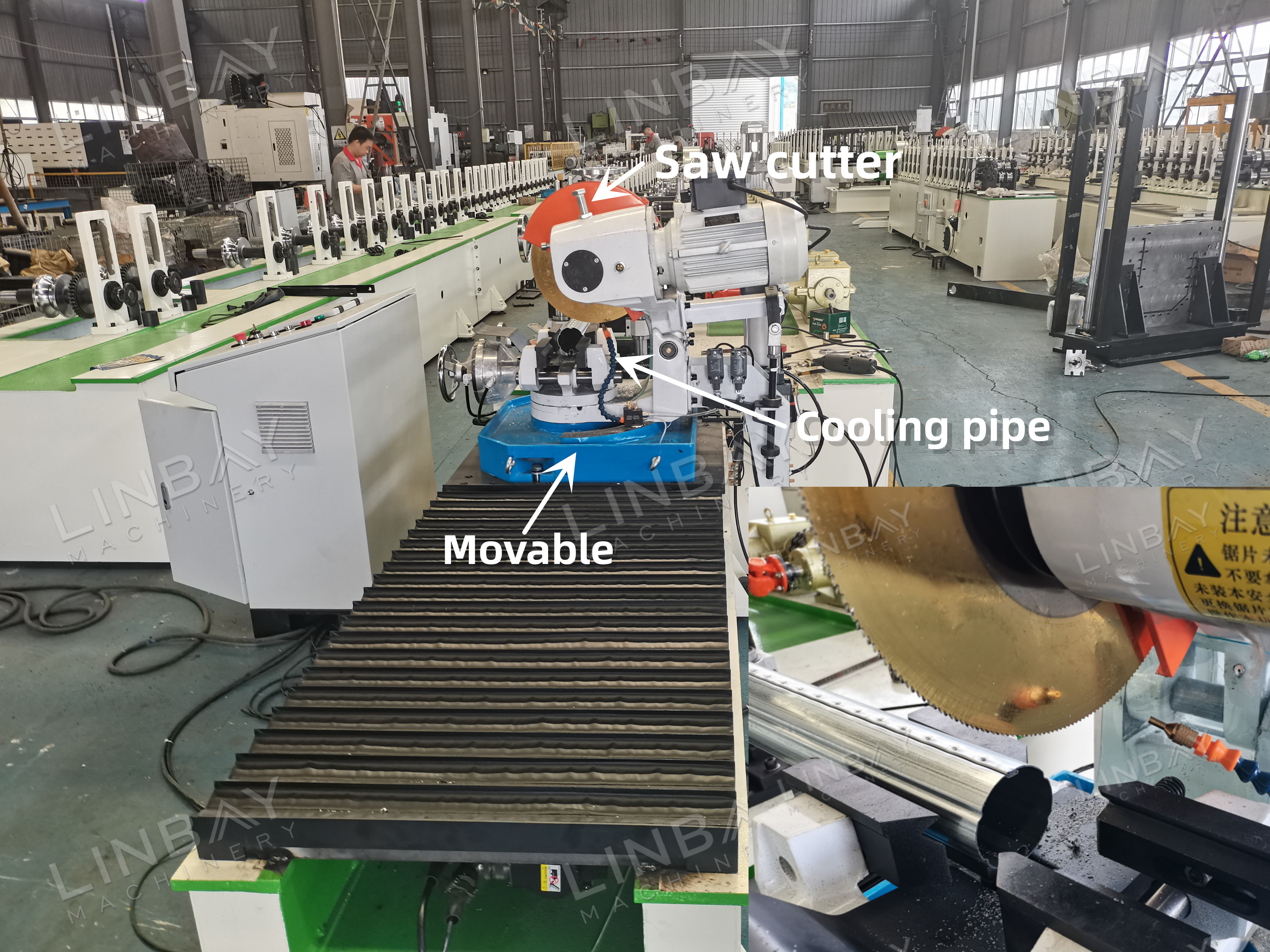

Flying Saw Cut

· Multi-diameter Saw: E etselitsoe ho amohela boholo bo fapaneng ba li-tubes, ho thusa ho fokotsa litšenyehelo tsa ho khutlisa lehare.

· Precision Cutting: E netefatsa likheo tse hloekileng, tse se nang deformation, tse nang le likarolo tse boreleli, tse se nang burr.

· Tšebeliso e Ntle ea Lintho: E felisa litšila ka sehiloeng se seng le se seng, e ntlafatsa tšebeliso ea tšepe ea tšepe le ho fokotsa litšenyehelo.

· Ntlafatso ea Lebelo la Tlhahiso: Sehlopha sa cutter se tsamaea ka pina ka lebelo le ts'oanang le mokhoa oa ho theha, ho nolofalletsa ts'ebetso e sa sitisoeng.

· Ho Nepaha ha Phahameng: E kopantsoe le motlakase oa servo le molaoli oa motsamao, ho boloka ho nepahala ho itšeha ka har'a mamello ea ± 1mm.

· Mokhoa o pholileng oa ho pholisa: Recirculates coolant ho boloka lehare la sakha le pholile, ho netefatsa boleng bo tsitsitseng ba ho itšeha nakong ea tšebeliso e tsoelang pele le ho lelefatsa bophelo ba lehare.

1. Decoiler

2. Ho fepa

3.Ho phunya

4. Litomo tsa ho etsa roll

5. Mokhoa oa ho khanna

6. Mokhoa oa ho khaola

Ba bang

Tafole e kantle