We pursue the administration tenet of “Quality is top-quality, Services is supreme, Popularity is first”, and will sincerely create and share success with all clients for Trending Products Lower Cost Galvanized Steel Sheet Door Frame Roll Forming Machine, We’ve been really aware of excellent, and have the certification ISO/TS16949:2009. We are dedicated to provide you good quality items with affordable price.

We pursue the administration tenet of “Quality is top-quality, Services is supreme, Popularity is first”, and will sincerely create and share success with all clients for door frame forming machine, metal door frame roll making machine, Stainless steel door frame roll forming machine, After 13 years of researching and developing products and solutions, our brand can represent wide range of merchandise with outstanding quality in world market. Now we have completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

Description:

The Door Frame Roll Forming Machine include Roman Column Door frame Roll Forming Machine, Lace Door Frame Roll Forming Machine, Curved Door Frame Roll Forming Machine, Straight Door Frame Roll Forming Machine, Door Plank Roll Forming Machine etc. We offer any kinds of door frame roll forming machines according to your profile drawing.

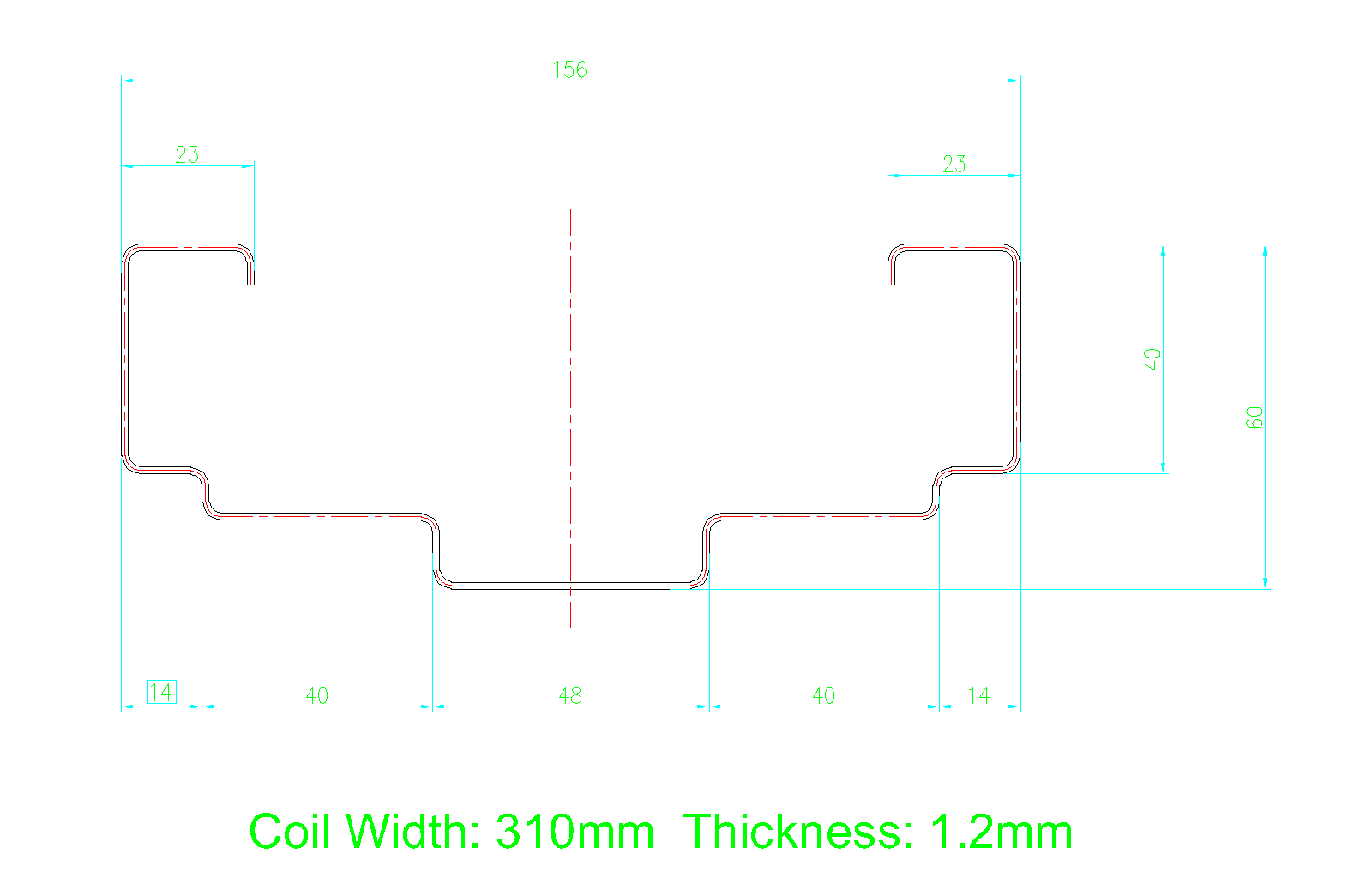

Profile:

Technical specification:

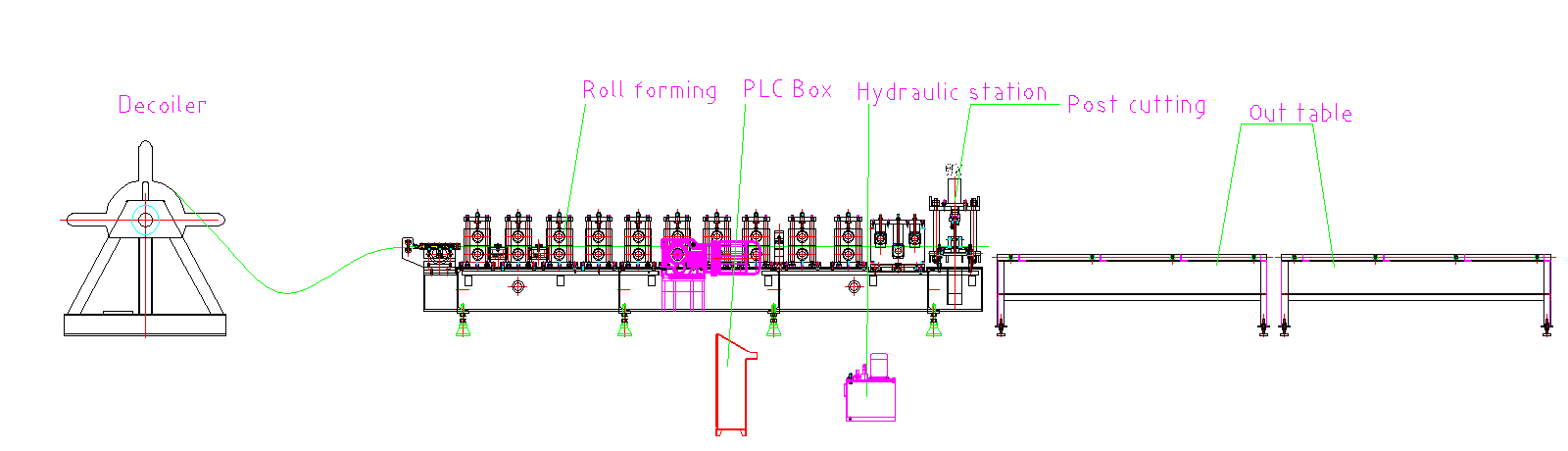

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table