video

Advantages

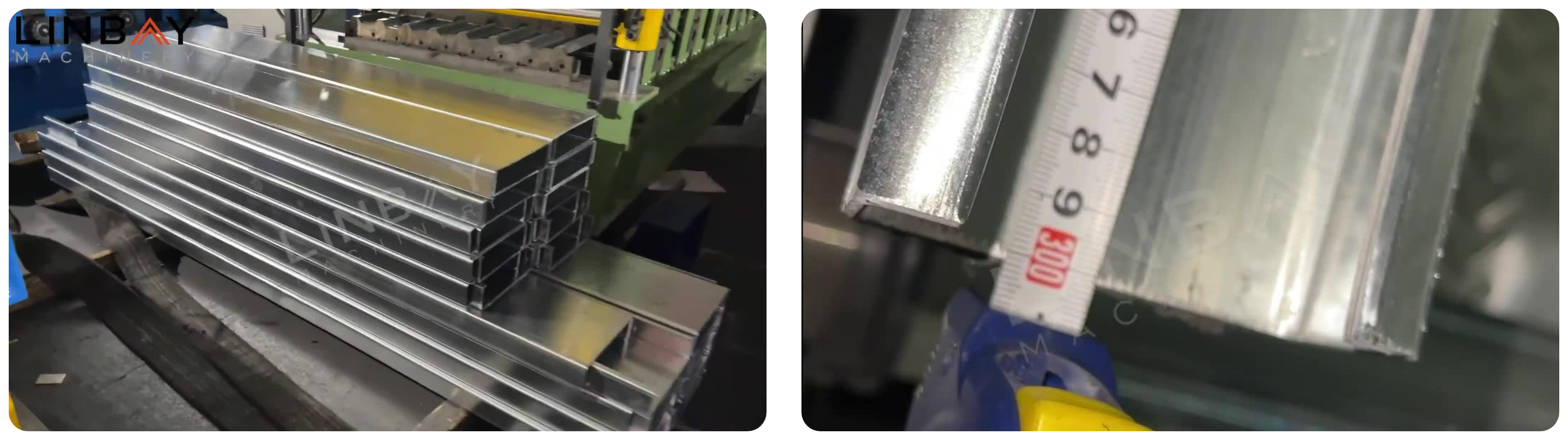

1. Produce purlins with varying widths and heights.

2. Automatic size adjustment, easy operation, and high efficiency.

3. Waste-free cutting.

Profile

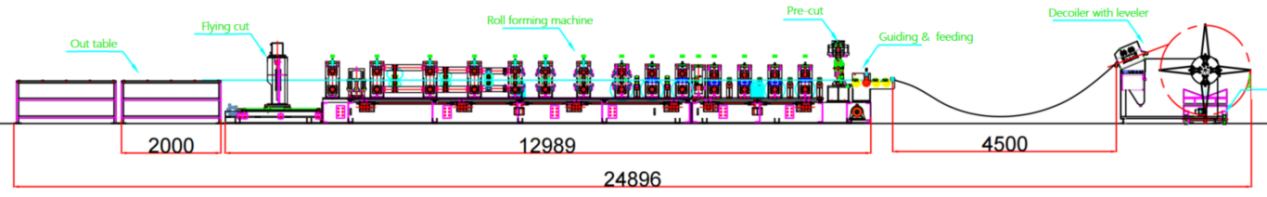

Flow chart

Decoiler with leveler-Guiding-Pre cut-Roll former-Flying hydraulic cutting-Out table

Decoiler with leveler

This is a combination machine that integrates a decoiler and a leveler, effectively saving factory space. When the steel coil thickness exceeds 1.5 millimeters or the material's yield strength surpasses 300 MPa, a leveler is essential. It removes irregularities in the steel coil, enhancing its flatness and parallelism, thereby improving the quality of the steel coil and the final purlin product.

We have also incorporated press-arm to secure the steel coils, preventing unexpected unwinding during the replacement process. An outward coil retainer further safeguard against coil slippage. These designs are implemented to ensure worker safety.

Guiding rollers

The steel coil passes through guiding rollers before entering the leveler. Multiple guiding rollers are strategically positioned to keep the steel coil aligned with the machine's central axis, preventing distortion in the formed profiles.

Pre cut

To facilitate the convenient and efficient switching of steel coils with different widths for various size production and to avoid material wastage, a pre-cut device has been designed.

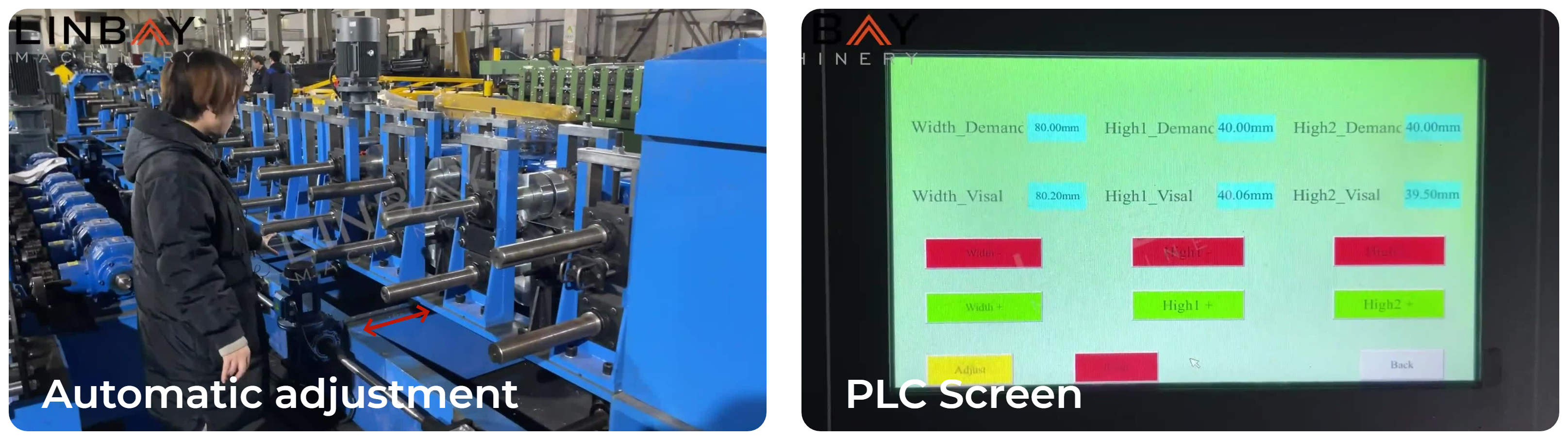

Roll former

This roll forming machine features a robust cast-iron structure, providing exceptional stability and durability. It is equipped with gearbox and universal joint driving system, ensuring efficient processing of 4mm thick steel coils with higher yield strength.

The machine is capable of producing purlins of varying heights and widths, with adjustments made via the PLC control panel. Motors and reducers facilitate the movement of forming stations on the rails, then variations in height and width are achieved by varying the gap between the left and right forming stations.

Flying hydraulic cutting

This cutting machine is powered by a hydraulic station. As depicted, a single set of blades can accommodate three different sizes. The slanted cutting machine resembles a pair of scissors, ensuring a smooth, burr-free and waste-free cutting surface. The term "Flying" signifies that the cutting machine can move back and forth in coordination with the roll forming machine's speed, without disrupting its continuous operation, thus enhancing productivity.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table