We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for Wholesale Discount China Steel Scaffolding Plank Walking Board Roll Forming Machine, Our tenet is clear many of the time: to deliver top quality product or service at competitive price to consumers round the globe. We welcome opportunity prospective buyers to speak to us for OEM and ODM orders.

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for China Scaffolding Making Machine, construction platform making machine, iron scaffold plank machine, Roll Forming Machine, scafflod roll forming machine, scaffold board rolling machine, scaffold foot pedal machine, scaffold panel, Scaffold plank roll forming machine, Scaffold Roll Forming Machine, scaffold step, scaffolding foot plate machine, scaffolding plate making machine, Scaffolding Platform machine, Scaffolding Platform making machine, Scaffolding Platform roll former, scaffolding walk plank machine, When It produced, it making use of the world’s major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a “people-oriented, meticulous manufacturing, brainstorm, make brilliant” company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we’ll be delighted to serve you.

Description

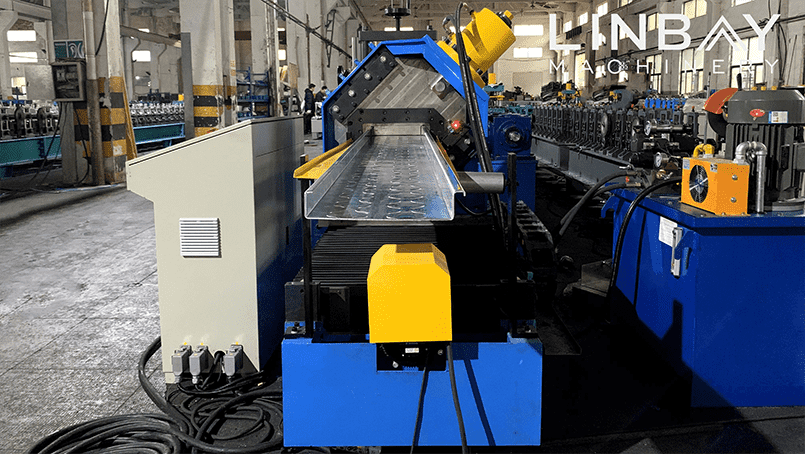

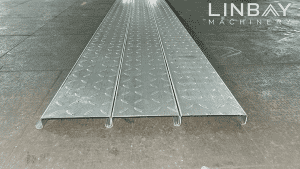

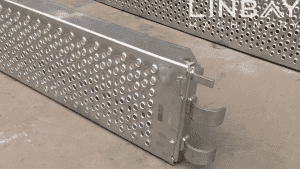

Scaffold plank roll forming machine can make scaffold plank. We adopt servo feeder to make sure the holes are in high precision. We use punching press to make line speed faster and we use hydraulic post cutting to make sure the profile perfect.

The thickness of raw material is around 1-2mm.

Application

Technical Specifications

Flaw Chart

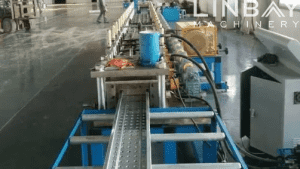

Manual decoiler–feeding–hydraulic punching station–forming machine–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

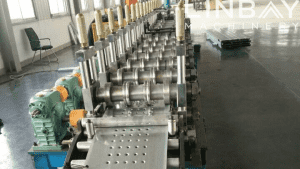

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table