Our intention would be to provide top quality products and solutions at competitive charges, and top-notch support to customers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Wholesale OEM China Double-Layer Color Steel Sheet Roof Panel Roll Forming Machine, Quality is factory’s life , Focus on customers’ demand is definitely the source of firm survival and progress, We adhere to honesty and great faith performing attitude, searching ahead towards your coming !

Our intention would be to provide top quality products and solutions at competitive charges, and top-notch support to customers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their quality specifications for China Roll Forming Machine Prices, Double Layer Roll Forming Machine, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer’s wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Description

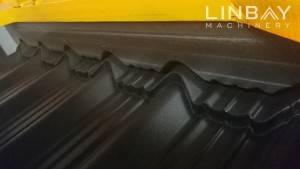

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

Technical Specifications

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):0.3-0.8 |

|||

|

Yield strength: 250 – 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

10-25 |

Or according to your requirement |

|

3 |

Forming station |

20-23 |

According to your profile |

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Chain drive |

Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Wall panel station |

Forged Iron station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

Flow Chart

Manual decoiler–feeding–roll forming–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Good quality China High Precision L Channel Stu...

-

Trending Products China Dixin New Metal Roofing...

-

OEM Supply China 2020 Customized Auto Changed C...

-

Newly Arrival China Kxd C Z Purlin Cold Roll Fo...

-

China Gold Supplier for China Water Gutter Roll...

-

Quality Inspection for High Speed Guardrail Rol...