We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for Wholesale Price Canton fair automatic steel door frame making machines, The principle of our corporation is always to give high-quality merchandise, expert service, and honest communication. Welcome all friends to place trial get for making a long-term enterprise partnership.

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for door frame roll making machine, price door frame roll forming machine, steel door frame roll former, At Current, our solutions have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

Description:

The Door Frame Roll Forming Machine include Roman Column Door frame Roll Forming Machine, Lace Door Frame Roll Forming Machine, Curved Door Frame Roll Forming Machine, Straight Door Frame Roll Forming Machine, Door Plank Roll Forming Machine etc. We offer any kinds of door frame roll forming machines according to your profile drawing.

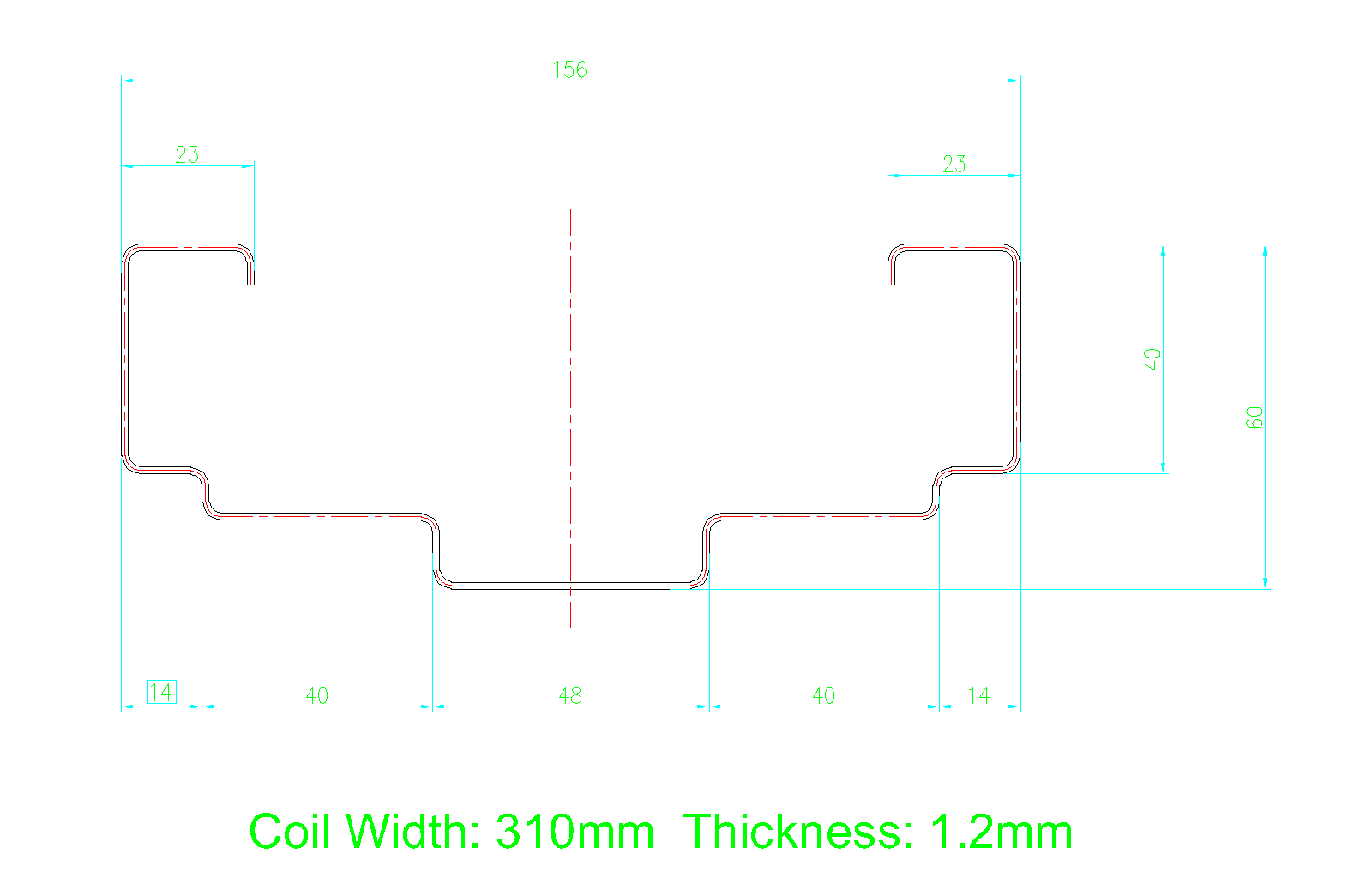

Profile:

Technical specification:

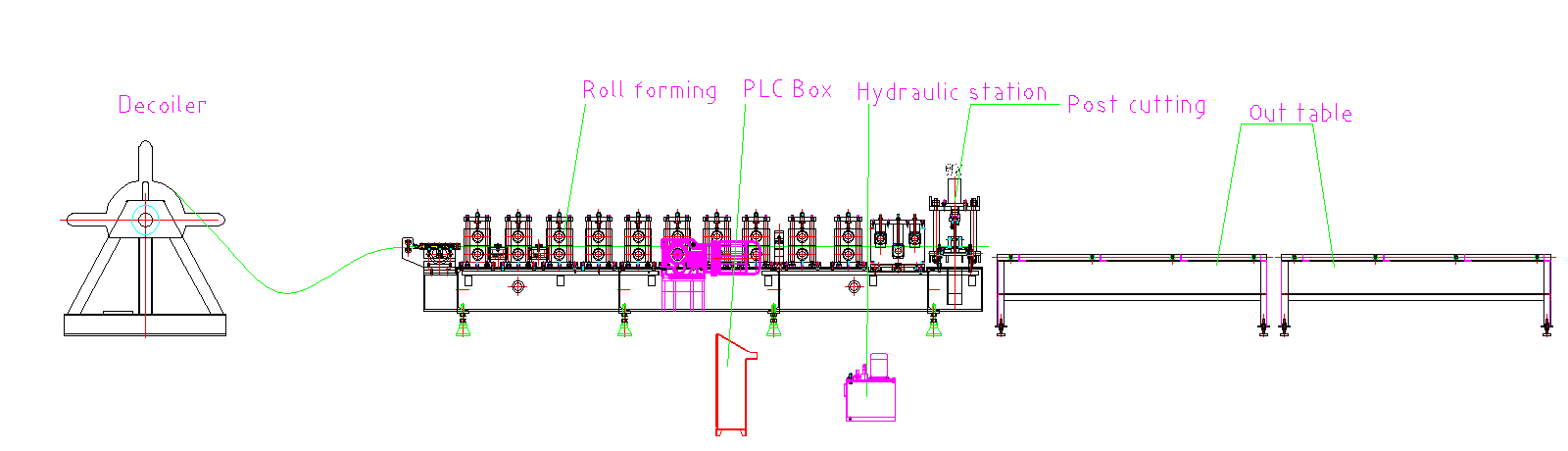

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table