ividiyo

Inkangeleko yesimo

Lo mgca wemveliso unokuvelisa ubukhulu obuhlukeneyo be-C-uhlobo, uhlobo lwe-Z, kunye nohlobo lwe-M-purlins kunye neqondo eliphezulu lokuzenzekelayo. Lukhetho lotyalo-mali olungabizi kakhulu.

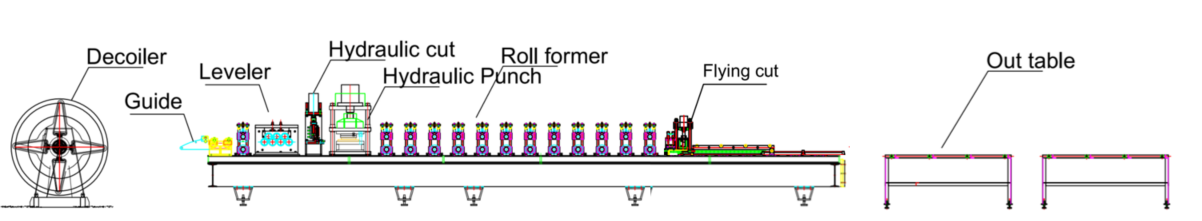

Itshathi equkuqelayo

I-Decoiler

Sifaka icofa-ingalokwi-decoiler ukubamba i-coil yensimbi kwindawo xa utshintsha ii-coil, ukuthintela ukukhululwa ngokukhawuleza kunye nokulimala okunokwenzeka kubasebenzi. Ukongeza,amagqabi akhuselayo entsimbizifakelwe ukuthintela ukutyibilika kwekhoyili ngexesha lokukhulula. Olu yilo alukhuseli kuphela i-coil yensimbi kunye nomatshini kodwa kwakhonaiqinisekisa ukhuseleko.

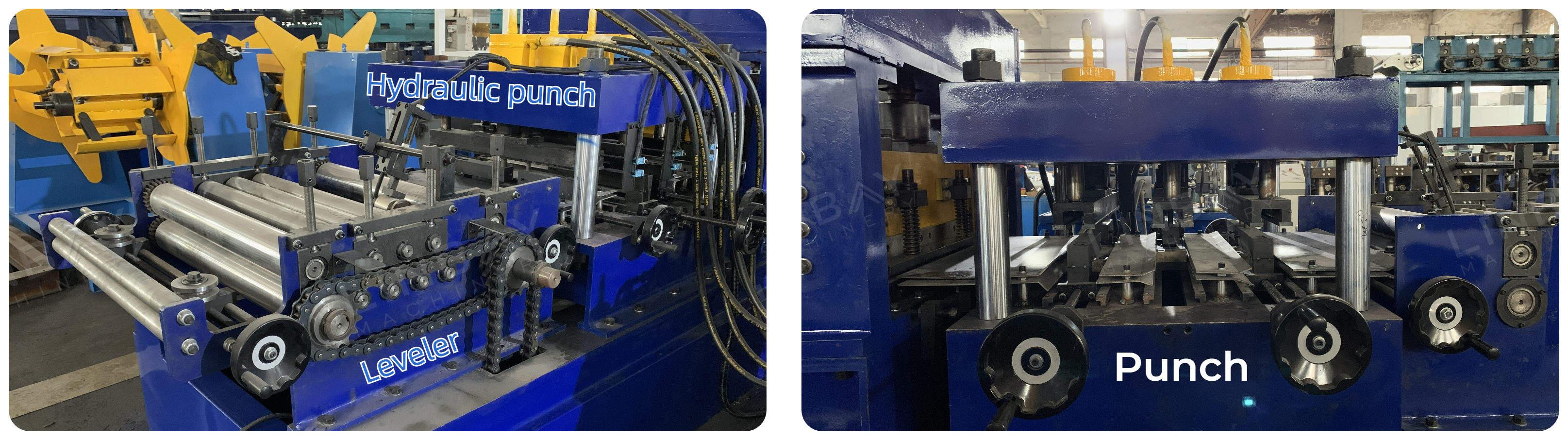

IsiKhokelo&Umgangatho

Iirola ezikhokelayo zigcina icoil yentsimbi kunye noomatshini kwiziko elifanayo ukuyaukuthintela ukugqwethekayeeprofayili ezenziweyo. Iirola ezikhokelayo ezininzi zibekwe ngobuchule ecaleni komgca wemveliso wonke. Kwaye ke, i-coil yensimbi ingena kwi-level, leyoisusa naziphi na izitenxo, iphucula ukucaba kunye nokuhambelanayekhoyili yentsimbi. Oku, kwakhona,iphucula umgangathozombini ikhoyili kunye nemveliso yokugqibela ye-purlin.

I-hydraulic punch

Umatshini wokubhoboza nge-hydraulic uza kunyeiiseti ezintathu zokufakunye neesilinda zeoli ezihambelanayo. Oku kufa kunokubangokukhawuleza kwaye kululailungiswe ukuhlangabezana neenkcukacha zabathengi, ukubonelelaukuguquguquka okugqwesileyo. Inkqubo yokutshintsha i-die iyasebenza kwaye ngokuqhelekileyo igqitywe ngaphakathiImizuzu emi-5.

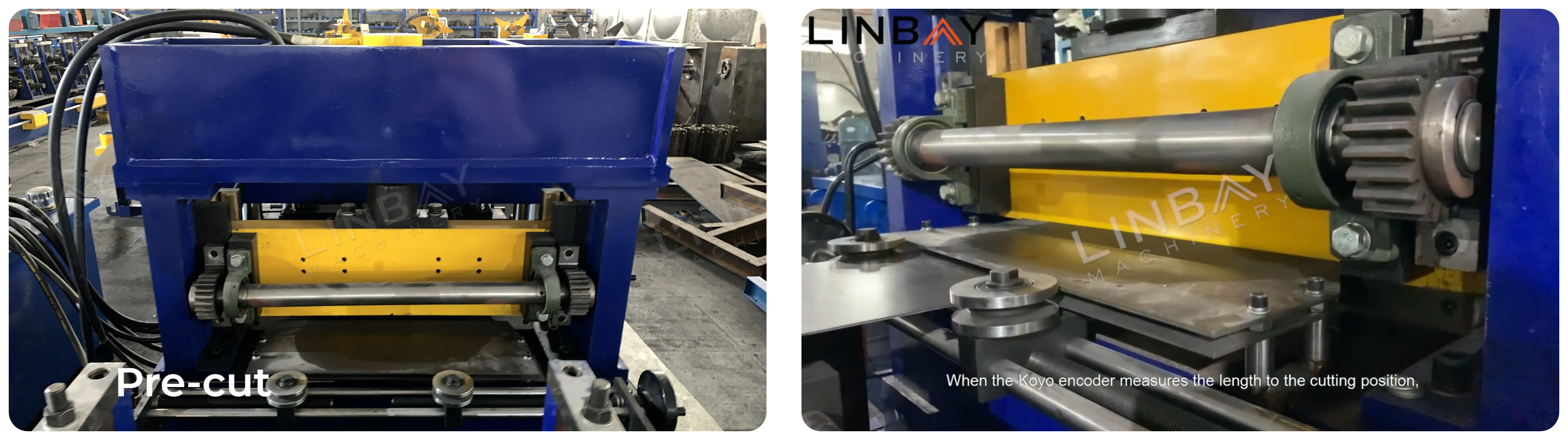

Ukusika kwangaphambili

Ukuququzelela ukutshintshwa ngokulula kobubanzi bekhoyili obahlukeneyo bokuvelisa ubukhulu obahlukeneyo kunye nokugcina imathiriyeli ekrwada, isixhobo sokusika kwangaphambili siyilelwe ukusebenza kakuhle,ukunciphisa inkunkuma.

I-level, umatshini wokubetha kunye nomatshini wokusika uhlanganiswe nomatshini wokwenza umqulu, oyinto enzima kakhuluuyilo olungabizi kakhulu.

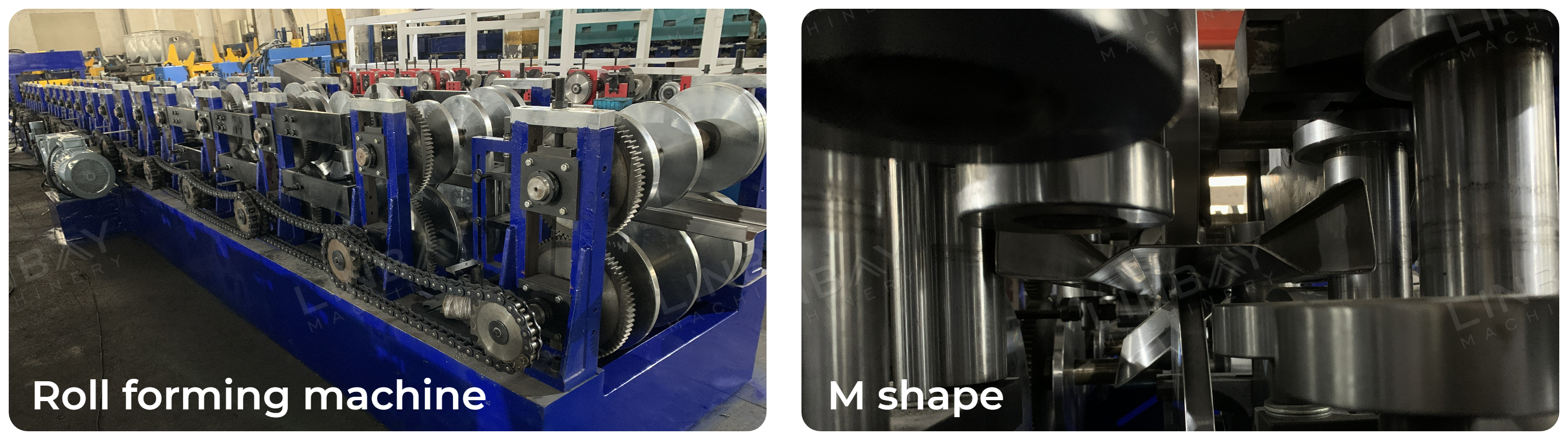

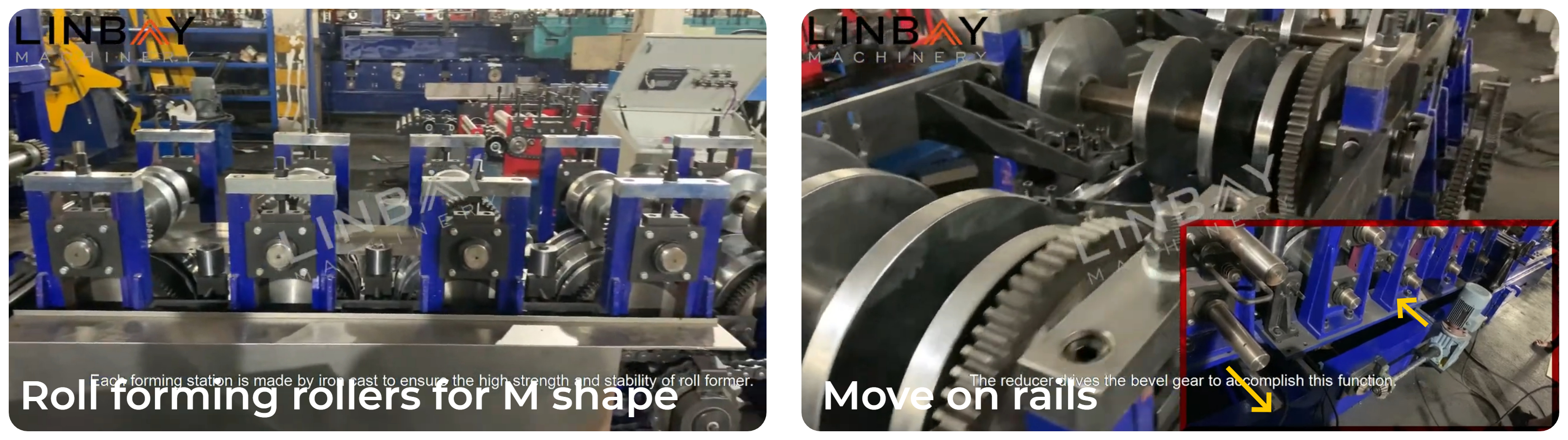

Roll yangaphambili

Umatshini wokwenza umqulu uneempawu aisakhiwo sentsimbikwayeinkqubo yokuqhuba ngetsheyini. Ulwakhiwo lwentsimbi yentsimbiintsimbi eqinileyo, ukuqinisekisa ukuqina kunye nokuzinza. Lo matshini uyakwazi ukuvelisaC, Z, kunye ne-Sigma purlins. Iirola ezine zokuqala zisetyenziselwa imilo ye-Sigma, kwaye ziyaphakanyiswa xa zenza iimilo ze-C okanye ze-Z. Ukongeza, ngokujikeleza ngesandla2-3 ukwenza izikhululo nge-180 °, ungatshintsha phakathi kokuvelisa i-C kunye ne-Z purlins. Izikhululo zokubumba kwicala elinye lomatshini zihamba ngeentsimbi zokuvelisa i-purlinsububanzi obahlukeneyo. Kubalulekile ukuqaphela ukuba, xa siceliwe, sinokwenza oomatshini be-purlin abahlukileyozombini ubude kunye nobubanzi obusezantsingaxeshanye.

Isitishi seHydraulic

Isikhululo sethu se-hydraulic sixhotyiswe ngefeni yokupholisa enceda ukugcina amaqondo obushushu afanelekileyo okusebenza, ukuqinisekisaukwandisa ukusebenza kakuhlengexesha lomsebenzi oqhubekayo.

I-Encoder&PLC

Abasebenzi banokulawula umatshini ngesikrini se-PLC, ukulungelelanisa imveliso si-peed, ukuseta imilinganiselo yemveliso, kunye nobude bokusika, njl. I-encoder idityaniswe kumgca wemveliso, iguqula ubude bekhoyili yentsimbi evakalayo ibe ziimpawu zombane ezigqithiselwe kwiphaneli yokulawula yePLC. Oku kuvumela umatshini wethu ukuba agcineukusika ukuchaneka ngaphakathi kwe-1mm, eqinisekisa iimveliso ezikumgangatho ophezulu kunyeukunciphisa inkcitho yezinto eziphathekayongenxa yeempazamo zokusika.

Sinikezela ngeenkonzo zokwenza ngokwezifiso, kubandakanywa kodwa kungaphelelanga kwiimodeli zeemoto, iibrendi, iimpawu zecandelo lombane, kunye nolwimi lwephaneli yolawulo yePLC.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile