ividiyo

Inkangeleko yesimo

Umsele:Iigatha zesinyithi ziqhele ukusetyenziselwa ukuhambisa amanzi emacaleni ophahla lwesakhiwo, ikakhulu ukuqokelela kunye nomjelo wamanzi emvula. Izimbo eziqhelekileyo zibandakanyahalf-ngeenxa zonkeuhlobokunye noK-isimbouhlobo. Ngokuqhelekileyo zenziwe ngezinto zetsimbi ukusuka kwi-0.3-0.8mm, ezifana ne-aluminium, intsimbi epeyintwe ngaphambili, okanye intsimbi.

Umnqwazi womphetho:Umqoloikepusiyiisetiapho amacala amabiniMbiniuphahlaiiphaneliukuhlangabezana, eyaziwa ngokuba uphahlaphezulu. Kuqhelekilesebenzisad ukunyusa ukutywinwa kunye nobuhle bophahla. Ii-Ridge caps zihlala zenziwe ngentsimbi epeyintwe ngaphambili okanye isinyithi esine-galvanized ukusuka kwi-0.3-0.8mm.

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

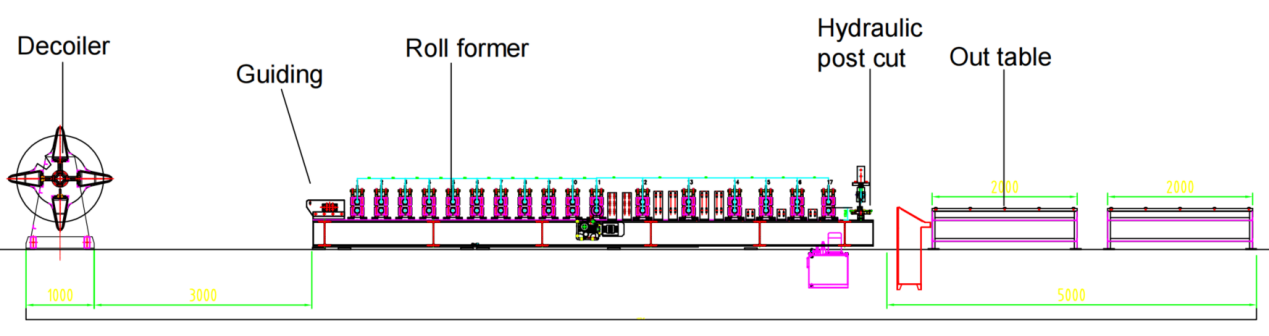

Itshathi equkuqelayo: I-Decoiler--Isikhokelo--Roll ukwenza umatshini--Hydraulic cut--Out table

- I-1.Ridge cap-Line isantya: 0-12m / min, adjustable

- Isantya se-2.Gutter-Line: 0-4m / min, ukulungiswa

- 3.Suyiizinto zetafile:Intsimbi, intsimbi epeyintwe kwangaphambili, ialuminiyam

- 4.Ubukhulu bezinto: 0.3-0.8mm

- I-5.Umatshini wokwenza i-Roll: Isakhiwo sephaneli yodonga kunye nenkqubo yokuqhuba ikhonkco

- I-6.Inkqubo yokusika: Yeka ukusika emva komatshini wokwenza umqulu, i-roll yangaphambili iyayeka xa usika.

- Ikhabhinethi ye-7.PLC: Inkqubo ye-Siemens.

Uluhlu lokupakisha lwetyala lokwenyani

- 1.I-Hydraulic decoiler*2

- 2.Umatshini wokwenza umqolo ophindwe kabini*1

- 3.Umatshini wokusika we-hydraulic we-double-row *1

- 4.Ngaphandle kwetafile*2

- 5.PLC iKhabhinethi yolawulo*1

- 6.Isikhululo samanzi*1

- 7.Ibhokisi yezahlulo ezisecaleni(Mahala)

Imeko yokwenyani-Inkcazo

- I-Decoiler

Kwi-ridge cap kunye ne-gutter, ukucwangciswa kwe-decoiler kuphantse kufane, kusetyenziswa i-hydraulic decoilers enomthamo womthwalo weetoni ezi-3 nganye. Ngenxa yobubanzi obahlukeneyo beekhoyili zentsimbi ezisetyenziselwa i-ridge cap kunye ne-gutter, kungcono ukwabelwa i-decoiler ezinikeleyo kumgca wemveliso ngamnye. Le ndlela inciphisa ixesha lokuphumla ngexesha lokutshintshwa kwekhoyili kwaye iphucula ukusebenza kakuhle kumgca ngamnye wemveliso.

Ukukhokela

Iiirola ezikhokelayo ziqinisekisa ulungelelwaniso phakathi kwekhoyili yentsimbi kunye ne ukwenza umquluumatshini, ukuthintela ukuphazamiseka ngexesha lenkqubo yokwenza.

Umatshini wokwenza umqulu

Lo matshini wokwenza umqulu usebenzisa isakhiwo sepaneli yodonga kunye nenkqubo yokuqhuba ikhonkco. Ngokungafaniyo noseto oluqhelekileyo lwemiqolo emibini ebonisa iisayizi ezimbini ezahlukeneyo zeprofayile efanayo, lo matshini uphatha iiprofayili ezahlukileyo ngokupheleleyo kumqolo ngamnye.

Kubalulekile ukuqaphela ukuba imiqolo emibini ayikwazi ukusebenza ngaxeshanye. Sincoma ukunikezela umgca wemveliso owahlukileyo kwiprofayili nganye ukuba unemfuno ephezulu yemveliso.

Ukongezelela, kufakwe izigqubuthelo zentsimbi phezu kwamatyathanga ukukhusela abasebenzi ekudibaneni ngengozi namatyathanga ajikelezayo kunye nokukhusela amatyathanga ekonakalisweni eluthulini nakwinkunkuma.

Ukusika kweHydraulic

Imishini yokusika igxininiswe kulo mgca wokuvelisa, ukumisa ukuhamba kwentsimbi yensimbi ngexesha lokusika. Kuba abathengi bafuna isantya esiphezulu sokuvelisa, sinikezela ngomatshini wokusika ondizayo ukuba isiseko sinokuhamba ngokutyibilikayo phambili nangasemva kwiireyile ngesantya esifanayo somatshini wokwenza umqulu. Olu lwakhiwo olutsha lwenza ukuba i-coil yensimbi iqhubele phambili ngomatshini wokwenza ngaphandle kokuphazamiseka ngexesha lokusika, ngaloo ndlela ikhulise kakhulu ukusebenza kakuhle komgca wokuvelisa.

Ekupheleni kwayo yomibini imiqolo, iincakuba zokusika ziyilwe ngobunono ukuze zihambelane ngokuchanekileyo neekhonto zeeprofayili ezifanelekileyo. Oku kuqinisekisa ukuba imida kwiiprofayili azichanekanga, zigcina imigangatho ephezulu yokuchaneka kunye nomgangatho.

Isitishi seHydraulic

Inika amandla okuqala kumsiki ngetanki yeoli evaliweyo. Icinyiwe ngaphandle kokusika, enokugcina amandla.

Isikhululo se-hydraulic sixhotyiswe ngefeni yokupholisa, iququzelela ukuchithwa kobushushu okusebenzayo ukuqinisekisa ukusebenza ixesha elide kunye nokufanelekileyo. Ngezinga eliphantsi lokungaphumeleli kunye nokuqina okukhethekileyo, isikhululo se-hydraulic siqinisekisa ukusebenza okuthembekileyo kwixesha elide.

Ikhabhathi yolawulo ye-PLC kunye ne-Encoder

Umgca wokwenza umqulu wemveliso uxhotyiswe nge-encoder form yaseJapan i-KOYO. I-encoder igcina ukuguqulela ubude obufunyenweyo beekhoyili zentsimbi kwimiqondiso yombane, idlulisela kwikhabhinethi yokulawula ye-PLC. Abaqhubi banokuhlengahlengisa isantya semveliso, ubuninzi, kunye nobude bokusika. Umatshini wokusika ufezekisa ukuchaneka okumangalisayo ngokubonga kumlinganiselo ochanekileyo we-encoder kunye nempendulo, ukugcina iimpazamo zokusika ngaphakathi kwe-± 1mm.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile