ividiyo

Iphrofayela

Lo mugqa wokukhiqiza ungakhiqiza osayizi abahlukene bohlobo lwe-C, uhlobo lwe-Z, nohlobo lwe-M-purlins ngezinga eliphezulu lokuzishintshashintsha. Kuyinketho yokutshala imali eyongayo.

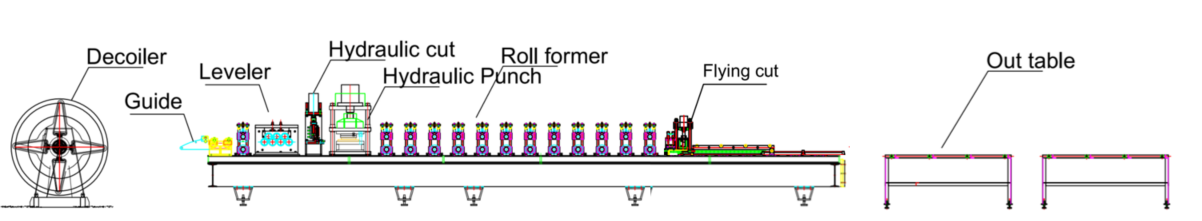

Ishadi eligelezayo

I-Decoiler

Sifaka acindezela-ingalokwi-decoiler ukuze ubambe ikhoyili yensimbi lapho ushintsha amakhoyili, ukuvimbela ukukhululwa kungazelelwe kanye nokulimala okungenzeka kubasebenzi. Ngaphezu kwalokho,amaqabunga ensimbi avikelayozifakwe ukuvikela ukushelela kwekhoyili ngesikhathi sokuqaqa. Lo mklamo awuvikeli kuphela ikhoyili yensimbi nomshini kodwa futhikuqinisekisa ukuphepha.

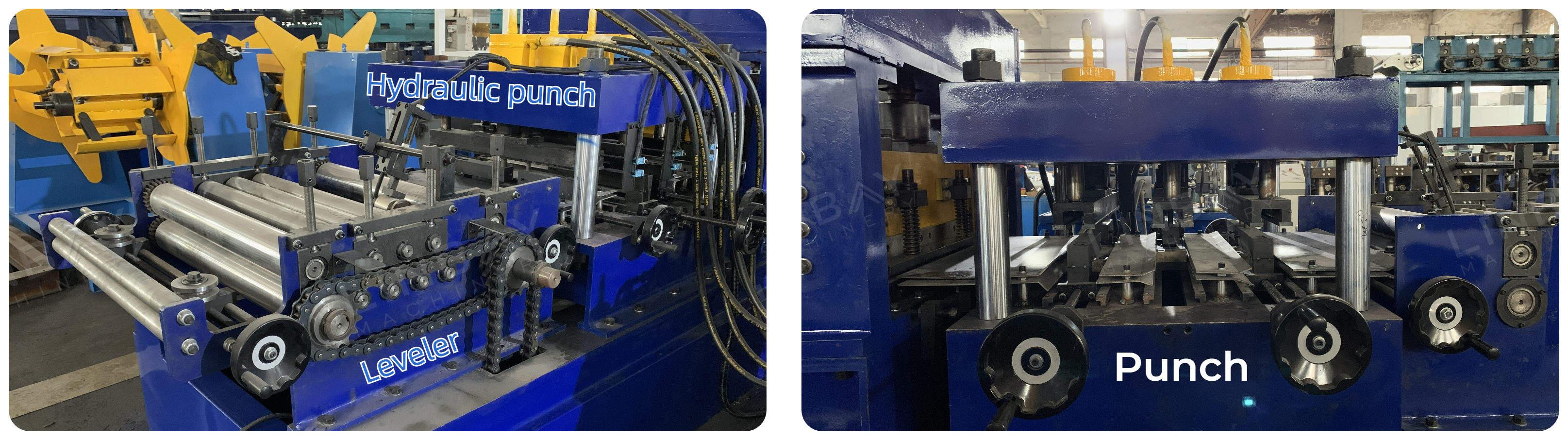

Ukuqondisa&Leveler

Amarola aqondisayo agcina ikhoyili yensimbi nemishini kumugqa ofanayo omaphakathi ukuyavimbela ukuhlanekezelayamaphrofayili akhiwe. Amarola amaningi aqondisayo abekwe ngendlela ehlelekile kuwo wonke umugqa wokukhiqiza. Futhi-ke, ikhoyili yensimbi ingena ku-level, okuyintoisusa noma yikuphi ukungahambi kahle, ithuthukise ukucaba nokuhambisanawekhoyili yensimbi. Lokhu-ke,ithuthukisa ikhwalithikokubili ikhoyili kanye nomkhiqizo wokugcina we-purlin.

I-punch ye-hydraulic

I-hydraulic punching machine iza nayoamasethi amathathu efanamasilinda amafutha ahambisanayo. Lezi zingafangokushesha futhi kalulailungiswe ukuze ihlangabezane nezidingo zekhasimende, ihlinzekeukuguquguquka okuhle kakhulu. Inqubo yokushintsha ifa iyasebenza futhi ngokuvamile iqedwa ngaphakathi5 amaminithi.

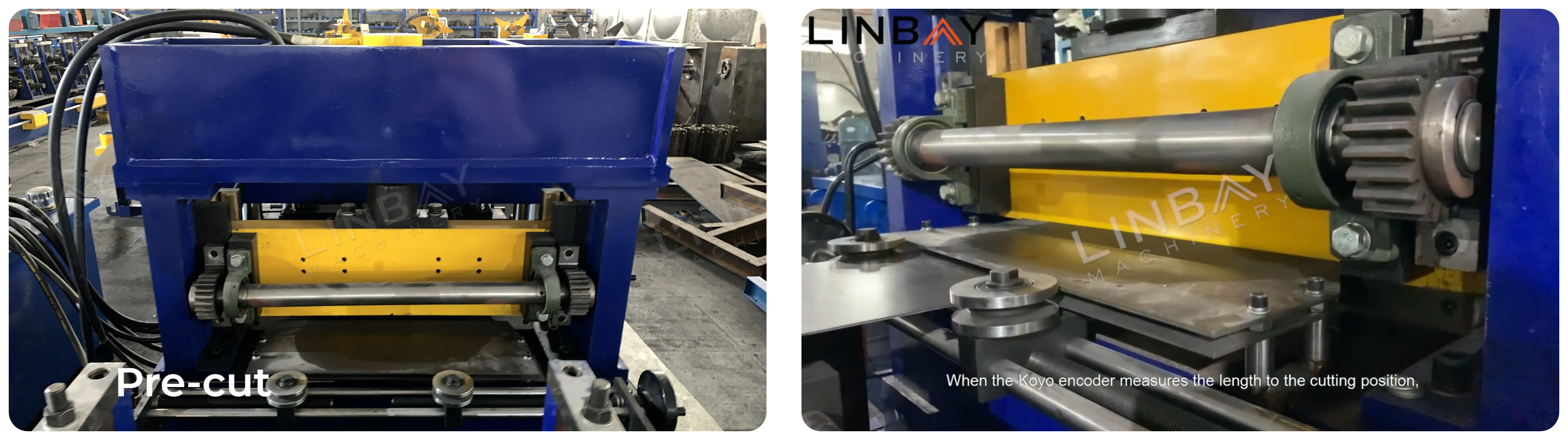

Ngaphambi kokusika

Ukuze kube lula ukushintshwa kobubanzi bekhoyili obuhlukene ukuze kukhiqizwe osayizi abahlukahlukene kanye nokugcina impahla eluhlaza, umshini wokusika ngaphambilini uklanyelwe ukusebenza kahle,ukunciphisa imfucuza.

I-level, umshini wokubhoboza kanye nomshini wokusika kuhlanganiswe nomshini wokwenza umqulu, okuyinto enhle kakhuluumklamo ongabizi kakhulu.

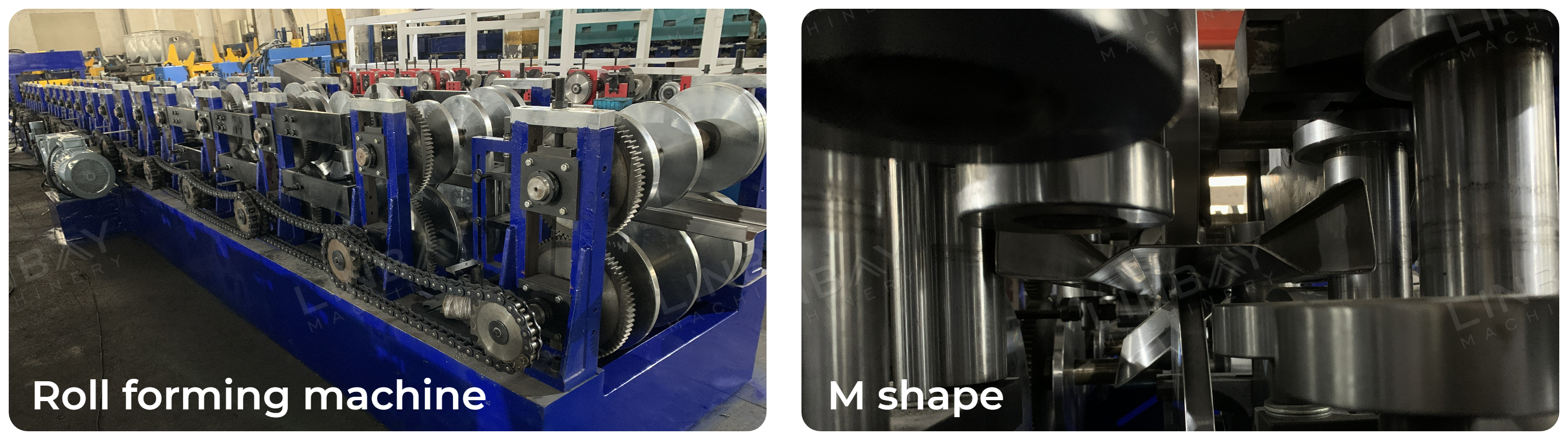

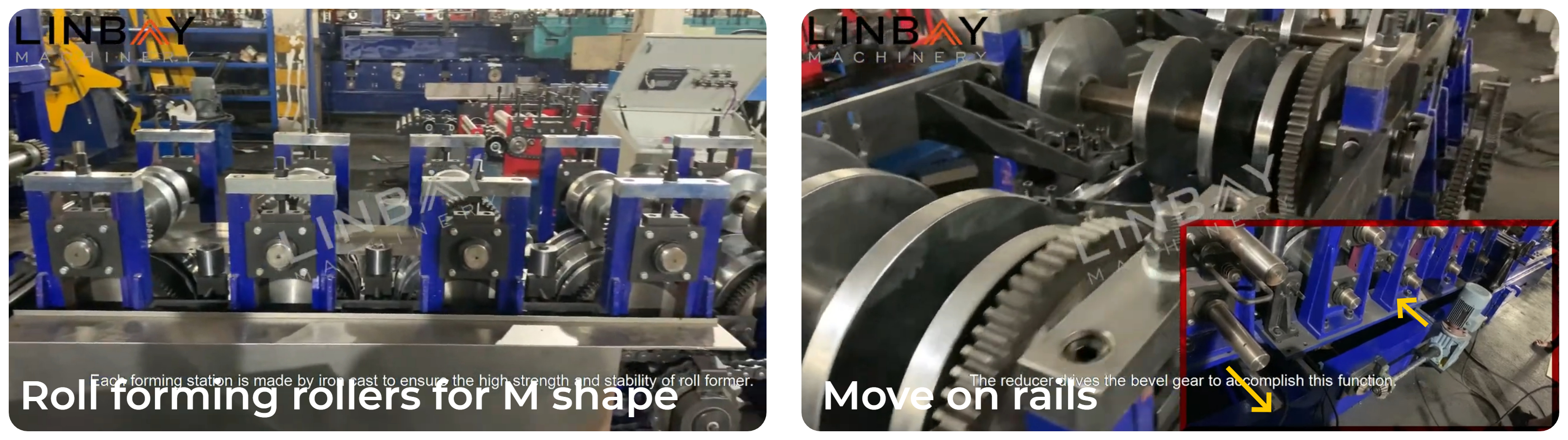

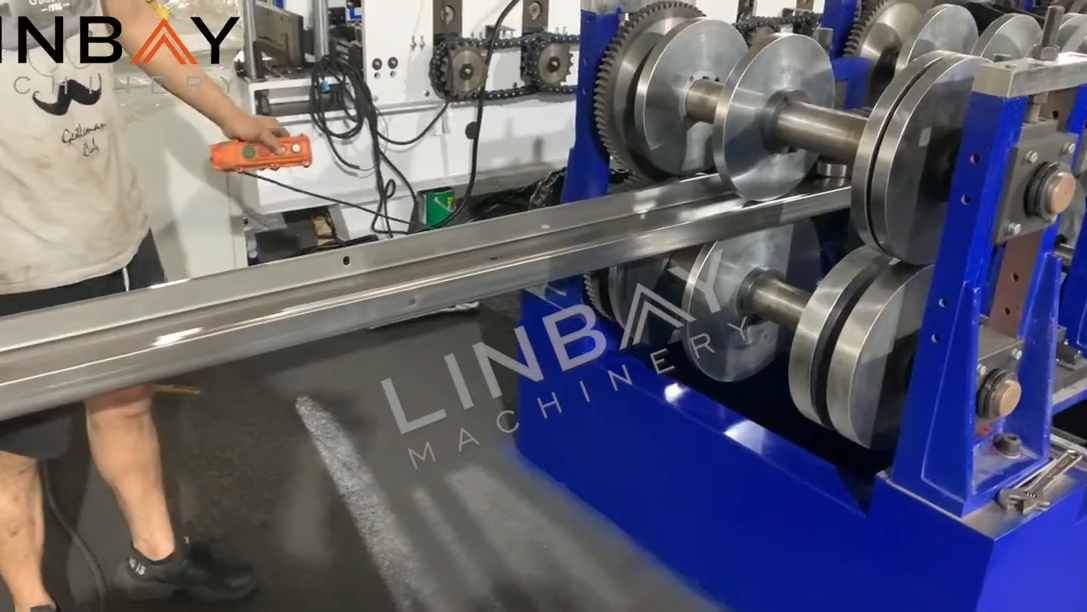

Roll ngaphambili

Umshini wokwenza umqulu uhlanganisa aukwakheka kwensimbifuthiuhlelo lokushayela lwe-chain. Isakhiwo se-cast-ironucezu lwensimbi oluqinile, ukuqinisekisa ukuqina nokuzinza. Lo mshini uyakwazi ukukhiqizaC, Z, kanye ne-Sigma purlins. Amarola amane okuqala asetshenziselwa umumo we-Sigma, futhi aphakanyiswa lapho enza umumo ongu-C noma u-Z. Ukwengeza, ngokuzungezisa mathupha2-3 ukwakha iziteshi ngo-180°, ungashintsha phakathi kokukhiqiza i-C ne-Z purlins. Iziteshi ezakha ohlangothini olulodwa lomshini zihamba kuma-rails ukukhiqiza ama-purlinsububanzi obuhlukene. Kubalulekile ukuqaphela ukuthi, ngesicelo, singakwazi futhi ukukhiqiza imishini ye-purlin ehlukahlukayokokubili ukuphakama nobubanzi obuphansikanyekanye.

Isiteshi samanzi

Isiteshi sethu se-hydraulic sifakwe isiphephetha-moya esipholile esiza ukugcina izinga lokushisa elilungile lokusebenza, siqinisekiseukusebenza kahle okwandisiwengesikhathi sokusebenza okuqhubekayo.

Isifaki khodi&PLC

Abasebenzi bangalawula umshini ngesikrini se-PLC, ukulungisa ukukhiqizwai-peed, ukubeka ubukhulu bokukhiqiza, nobude bokusika, njll. I-encoder ihlanganiswe emugqeni wokukhiqiza, iguqule ubude bekhoyili yensimbi ezwayo ibe amasiginali kagesi adluliselwe kuphaneli yokulawula ye-PLC. Lokhu kuvumela umshini wethu ukuthi unakekeleukusika ukunemba ngaphakathi kwe-1mm, eqinisekisa imikhiqizo esezingeni eliphezulu futhiukunciphisa udoti wezinto ezibonakalayongenxa yamaphutha okusika.

Sinikezela ngezinsizakalo zokwenza ngendlela oyifisayo, okuhlanganisa kodwa kungagcini nje ngamamodeli ezimoto, izinhlobo, izinhlobo zemikhiqizo kagesi, nolimi lwephaneli yokulawula ye-PLC.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle